A double girder overhead crane is a robust material handling equipment designed to lift and transport heavy loads in industrial settings.

A double girder overhead crane is a robust material handling equipment designed to lift and transport heavy loads in industrial settings. Engineered with two parallel main girders, it delivers superior stability and load-bearing capacity compared to single girder models, making it the go-to choice for heavy-duty applications such as steel mills, 제조 공장, 창고, 건설 현장. Whether you need to move machinery, 원료, 또는 완제품, our double girder overhead cranes combine precision, 내구성, and safety to optimize your workflow.

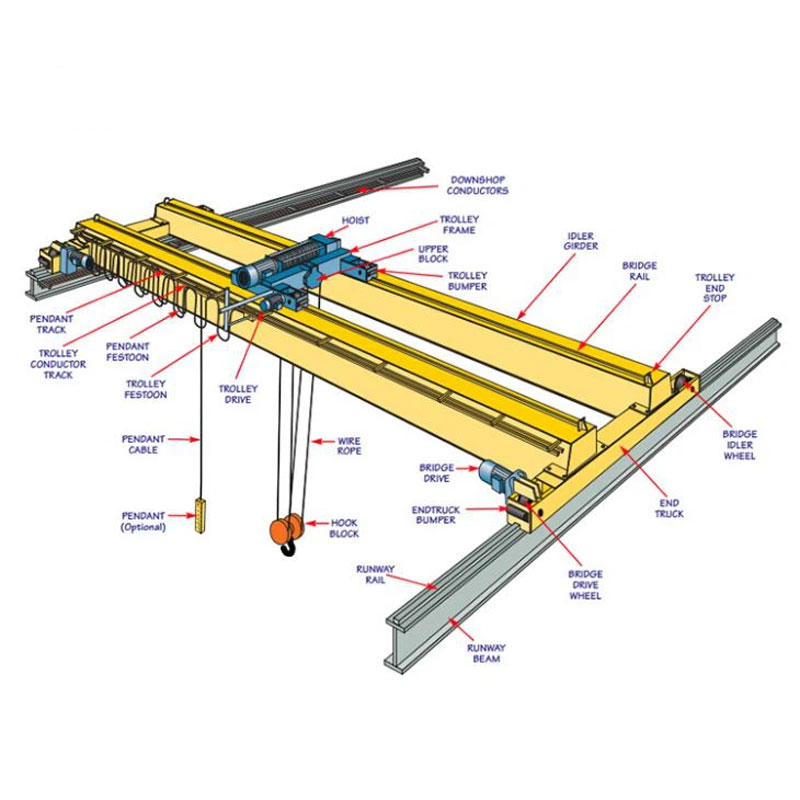

A double girder overhead crane is a type of bridge crane consisting of two horizontal main girders supported by end trucks (or end carriages) that run along elevated rails (runways) mounted on building columns or standalone structures. The crane’s lifting mechanism—typically a hoist or trolley—is mounted on a trolley that travels along the length of the main girders, allowing 360° coverage of the workspace below.

같지 않은 single girder overhead cranes, which rely on a single main beam, double girder designs distribute weight more evenly, enabling them to handle much heavier loads (often up to 500 톤 이상). This makes them essential for industries requiring frequent heavy lifting, where reliability and safety are non-negotiable.

Our double girder overhead cranes are built to excel in demanding environments. Here are their standout features:

|

매개 변수

|

범위/세부사항

|

|

최대 리프팅 용량

|

10 tons – 500 톤 (custom options available for higher loads)

|

|

스팬 길이

|

10m – 35m (custom spans on request)

|

|

리프팅 높이

|

6m – 30m (adjustable based on application)

|

|

호이스트 속도

|

0.5분/분 – 10m/분 (variable speed with frequency inverter option)

|

|

트롤리 이동 속도

|

5분/분 – 30m/분

|

|

크레인 이동 속도

|

10분/분 – 50m/분

|

|

노동 계급

|

A5 – A8 (ISO 표준; suitable for light to heavy-duty, continuous use)

|

|

전원 공급 장치

|

380V/3Ph/50Hz (customizable for 220V/440V or other regions)

|

|

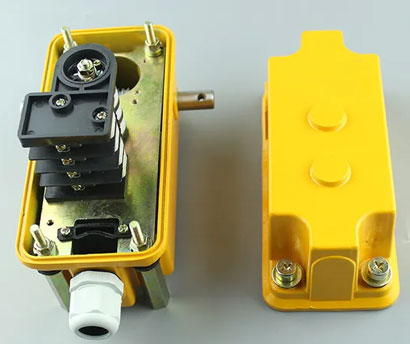

제어 모드

|

펜던트 제어, 원격 제어 (무선 전화), 또는 객실 제어

|

A double girder overhead crane consists of several key components working together to ensure efficient lifting and movement:

주요 대들보

Two parallel steel beams (girders) that form the bridge structure. They bear the load of the trolley and the lifted material, requiring high strength and rigidity.

엔드 트럭

Mounted at both ends of the main girders, these house the wheels and motors that drive the crane along the runway rails.

트롤리

A movable unit that travels along the top or bottom of the main girders. It carries the hoist and is powered by its own motor for horizontal movement.

감아 올리기

The lifting mechanism, including a crane drum, wire rope/cable, 그리고 크레인 후크. It is responsible for raising and lowering loads, with options for electric or hydraulic operation.

전기 시스템

모터 포함, 제어판, 스위치, and wiring to power and operate the crane, 트롤리, 그리고 호이스트.

Overload limiters, 여행 제한 스위치, 비상 정지 시스템, and anti-sway devices to ensure safe operation.

Q1: What’s the difference between a double girder and single girder overhead crane?

에이: 이중 대들보 크레인에는 두 개의 주요 대들보가 있습니다., 더 높은 부하 용량 제공 (10+ 톤) 안정성, making them suitable for heavy-duty use. Single girder cranes have one main girder, 더 가볍다, and better for lighter loads (최대 10 톤) in smaller workspaces.

Q2: Which industries use double girder overhead cranes?

에이: They are widely used in steel mills, automotive manufacturing, 조선소, 건설 현장, 창고 (for heavy pallet handling), and power plants.

Q3: How often should a double girder overhead crane be maintained?

에이: 정기점검 (매일 착용 점검, 매끄럽게 하기) and professional maintenance (every 6–12 months) are recommended to ensure safety and longevity.

Q4: Can double girder cranes be customized for specific applications?

에이: 예. We offer customizations for load capacity, 기간, 리프팅 높이, 제어 시스템, and specialized attachments (예를 들어, magnets for metal handling, grabs for bulk materials).

Q5: Are double girder overhead cranes compliant with international safety standards?

에이: Our cranes meet ISO, FEM, 및 OSHA 표준, with built-in safety features to ensure compliance with global industrial regulations.

PDF로 공유: 다운로드

우리는 귀하의 의견을 소중히 여깁니다! 귀하의 특정 요구에 맞게 서비스를 조정할 수 있도록 아래 양식을 작성하십시오..

최신 의견