Overhead crane wheels are responsible for bearing the full load of the crane and the lifted materials, while simultaneously facilitating smooth and precise longitudinal travel along the runway. Engineered for extreme durability and reliability, these wheels are a fundamental part of ensuring the safety, 능률, and longevity of your material handling operations. They are typically mounted on wheel forks or end trucks and are driven by motors or move freely as idler wheels.

| 매개 변수 | 사양 | 메모 |

| 휠 직경 | 250mm – 800mm (10″ – 32″) | 맞춤형 직경 이용 가능 |

| Wheel Width (Tread) | 90mm – 200mm (3.5″ – 8″) | Varies with load capacity |

| 보어 직경 | 60mm – 200mm (2.4″ – 8″) | Matched to standard bearing sizes |

| 플랜지 높이 | 20mm – 35mm (0.8″ – 1.4″) | 기준 & custom profiles |

| 재료 등급 | 55# 강철, 65MN, 42CRMO, SS | Alloy steel 42CrMo is common for heavy-duty |

| 표면 경도 | HRC 55-60 | Hardened depth: 15-20mm |

| 코어 경도 | HB 240-280 | 인성과 내충격성을 보장합니다. |

| Max Load Capacity | 5 Tons – 100+ Tons per wheel | Dependent on wheel size and material |

메모: The above parameters are general. Exact specifications must be determined based on your crane’s design and operational requirements.

We offer a comprehensive range of overhead crane wheels to meet diverse needs.

1. 이중 플랜지 휠: 가장 일반적인 유형, with flanges on both sides to securely guide the crane along the runway rail, preventing derailment.

2. 단일 플랜지 휠: Used in specific configurations where one side of the wheel runs against a guide, often found in specialized crane systems or to compensate for tracking issues.

3. Flangeless (Plain) 바퀴: 별도의 수평 가이드 롤러와 함께 사용됩니다.. Common in very heavy-duty applications like furnace charging cranes or where lateral forces are high.

1. Drive Wheels: Feature a machined groove or keyway on the tread or side to engage with a drive pinion or are directly driven via a shaft. They provide the motive force for the crane.

2. Idler (Free-Running) 바퀴: These wheels are not driven and rotate freely, supporting the load and following the movement of the driven wheels.

1. Standard Steel Wheels: For general indoor industrial use.

2. 합금 강철 바퀴: For heavy-duty, high-cycle applications (예를 들어, 42CRMO).

3. Heat-Treated Steel Wheels: For extreme duty cycles and maximum wear resistance.

4. Stainless Steel Wheels: For corrosive environments (food processing, 화학공장).

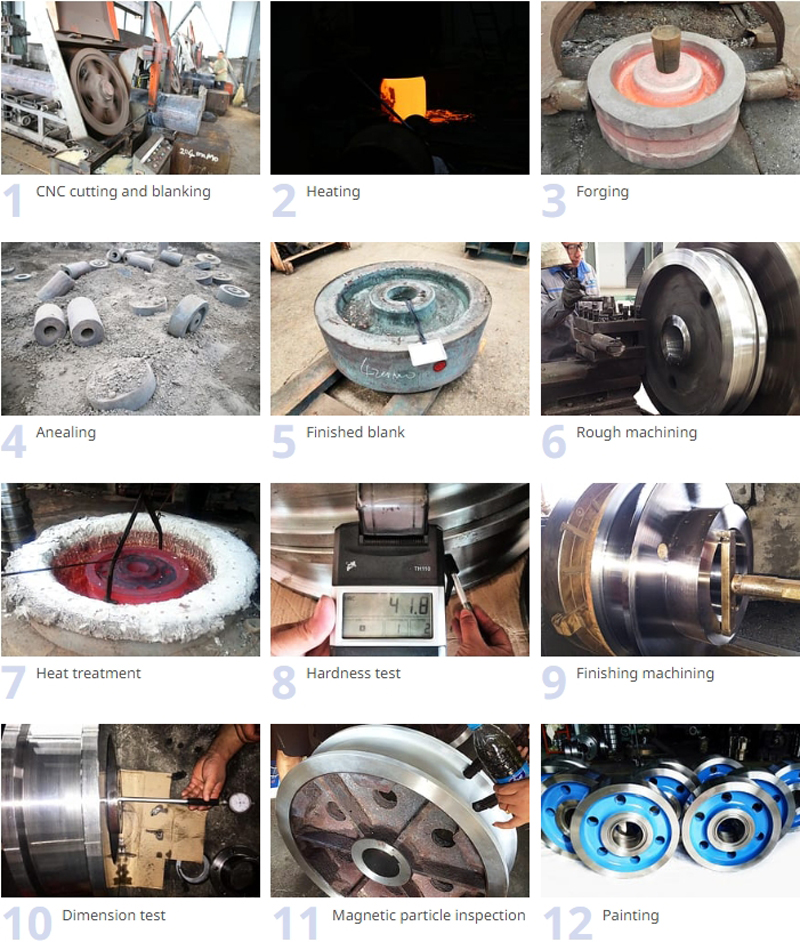

5. 단조 강철 바퀴: For the most demanding applications requiring superior strength and impact resistance.

Q1: How do I know when my overhead crane wheels need to be replaced?

에이: Regular inspection is key. 일반적인 징후는 다음과 같습니다:

Q2: Can I replace just one worn wheel?

에이: It is highly recommended to replace wheels in sets on the same end truck or, ideally, across the entire crane bridge. Replacing only one wheel can lead to uneven load distribution, causing rapid and uneven wear on the new wheel and potential alignment issues.

Q3: What is the difference between flame hardening and induction hardening?

에이: Both processes harden the wheel’s surface.

Q4: How important is the wheel hardness compared to the rail hardness?

에이: It is crucial. Ideally, the crane wheel should be harder than the rail. A harder wheel will wear down slower, transferring the wear to the rail, which is typically longer, cheaper, and easier to replace than a wheel set. A common rule is for the wheel to be 20-40 HB points harder than the rail.

Q5: Do you provide custom-made wheels?

에이: 예, we specialize in providing custom solutions. We can manufacture wheels to your specific drawings, including non-standard diameters, widths, bore sizes, and special heat treatment requirements. Please provide your technical specifications for a quotation.

Q6: What information do I need to provide to order the correct replacement wheel?

에이: To ensure a perfect fit, please provide:

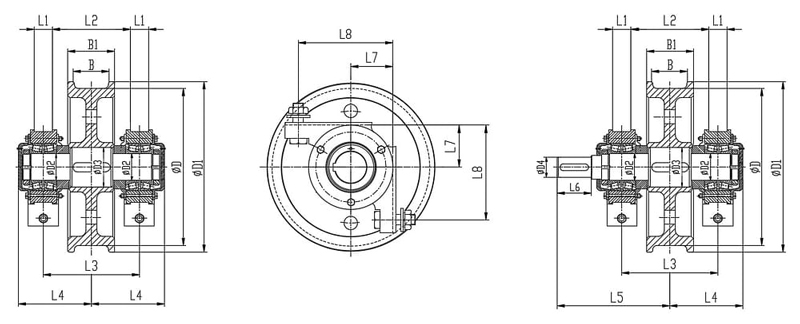

1. Wheel Outside Diameter and Tread Width.

2. Bore Diameter and Keyway Dimensions (해당되는 경우).

3. Flange Height and Profile.

4. Overall Width of the Wheel.

5. Photos of the old wheel and the assembly can also be very helpful.

우리는 귀하의 의견을 소중히 여깁니다! 귀하의 특정 요구에 맞게 서비스를 조정할 수 있도록 아래 양식을 작성하십시오..

최신 의견