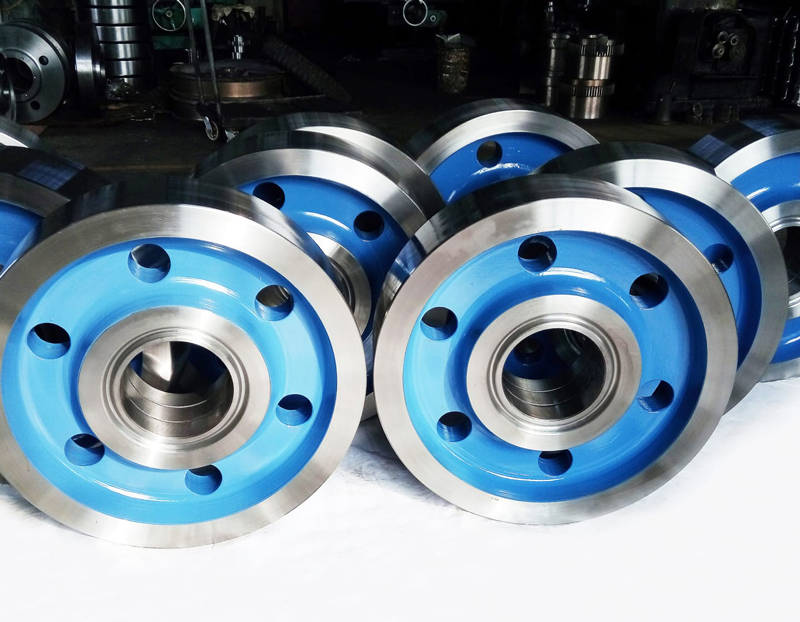

Forged crane wheels are core load-bearing components in various industrial crane systems, playing a critical role in ensuring the stable, 안전한, and efficient operation of cranes. Manufactured through advanced forging processes, these wheels exhibit exceptional mechanical properties, 내마모성, 및 내하중 능력, making them indispensable for heavy-duty material handling scenarios across industries.

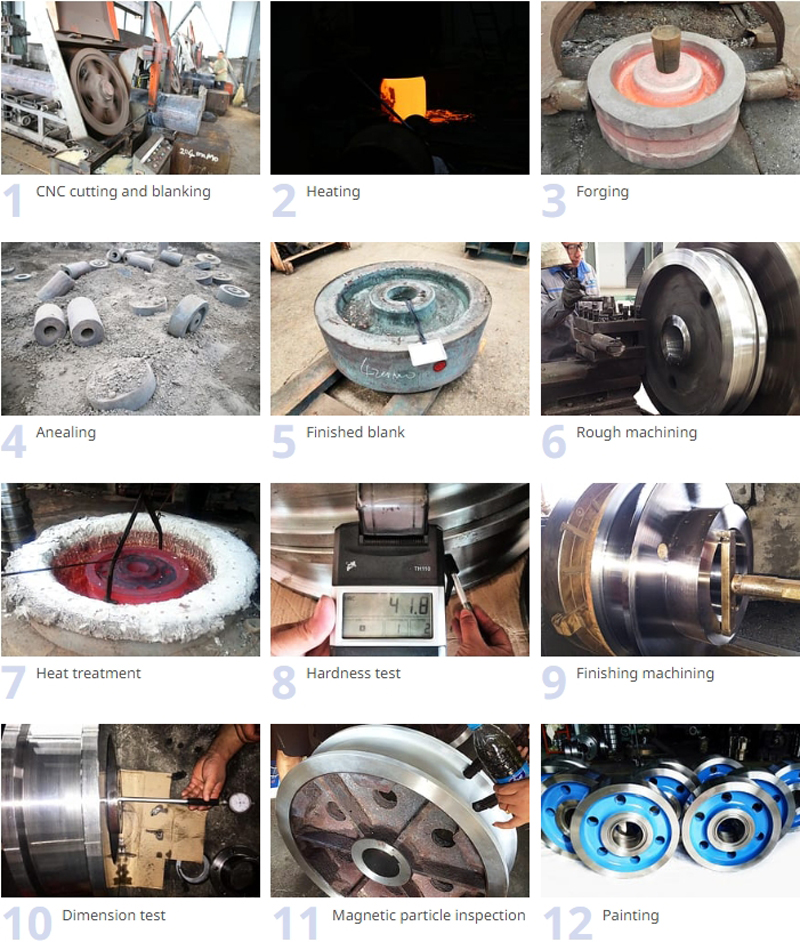

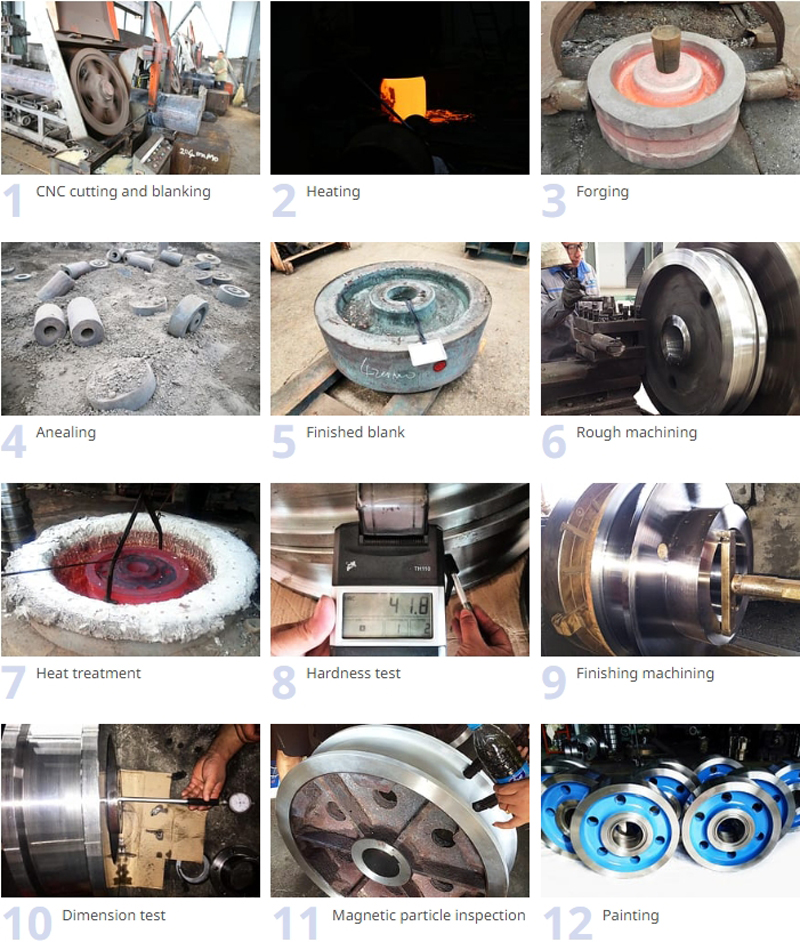

Forged Crane Wheels Advanced Manufacturing Process

Our forged crane wheels are produced using a strict and sophisticated forging process, ensuring superior quality and performance:

- 1. High-Quality Raw Material Selection: We adopt high-strength alloy steels (42CrMo와 같은, 60Si2Mn, 등.) as raw materials. These materials have excellent toughness, 경도, 그리고 피로 저항, laying a solid foundation for the durability of the crane wheels.

- 2. 정밀 단조: The raw materials are heated to the optimal forging temperature (typically 1100-1250°C) and then subjected to repeated die forging. This process refines the metal grain structure, eliminates internal defects (such as porosity and segregation), and enhances the material’s density and mechanical strength.

- 3. 열처리: 단조 후, the crane wheels undergo quenching and tempering heat treatment. Quenching improves the surface hardness and wear resistance, while tempering reduces internal stress and improves toughness, achieving an ideal balance between hardness and toughness.

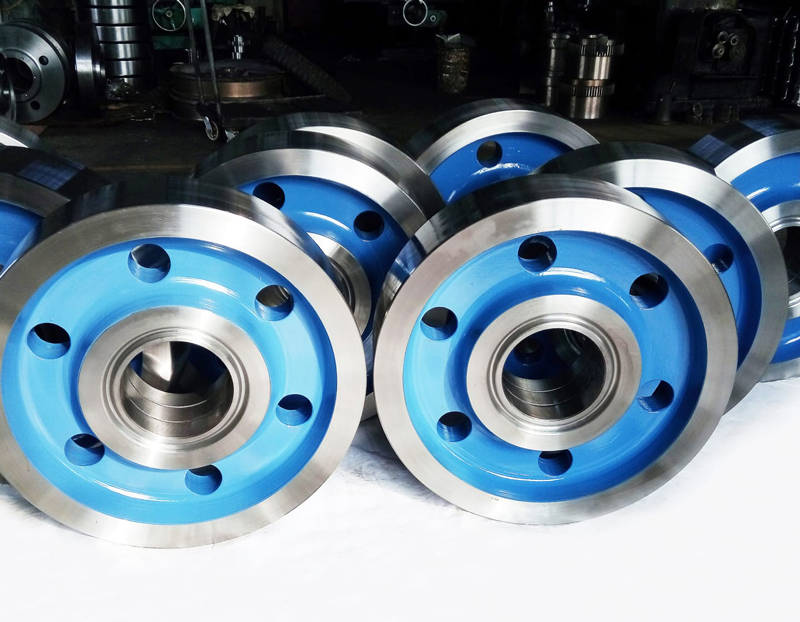

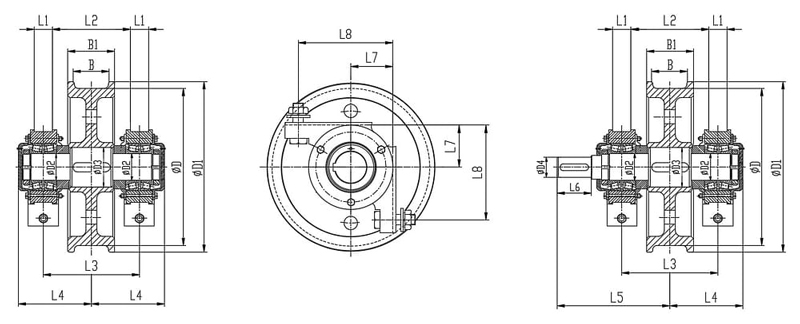

- 4. 정밀 가공: The heat-treated blanks are processed through CNC lathes, grinders, and other precision equipment to ensure strict dimensional accuracy (직경 포함, 너비, 동심도, and surface roughness) that meets or exceeds industry standards.

Outstanding Product Features & 장점

- 1. 고강도 & Load-Bearing Capacity: The forging process significantly improves the material’s tensile strength and yield strength. Our forged crane wheels can withstand extremely high loads, ranging from tens of tons to hundreds of tons, adapting to the heavy-duty requirements of large cranes.

- 2. Excellent Wear Resistance: The quenched surface of the wheels has a high hardness (HRC 45-55), which effectively reduces wear caused by long-term contact and friction with crane rails. This extends the service life of the wheels, reducing replacement frequency and maintenance costs.

- 3. Superior Fatigue Resistance: The refined grain structure and reasonable heat treatment process make the crane wheels have strong fatigue resistance. They can resist the alternating loads generated during crane operation for a long time without cracking or deformation, ensuring operational safety.

- 4. Precise Dimensional Accuracy: Advanced CNC machining technology ensures that the dimensional tolerance of the wheels is controlled within a very small range. This guarantees smooth matching with crane axles and rails, reducing vibration and noise during operation, and improving the overall stability of the crane.

- 5. Stable Performance Consistency: Strict quality control throughout the production process (from raw material inspection to finished product testing) ensures that each batch of forged crane wheels has consistent performance, avoiding quality fluctuations that may affect crane operation.

Wide Application Scenarios

Our forged crane wheels are widely used in various types of cranes and industrial equipment, 포함하되 이에 국한되지는 않습니다.:

- 1. Bridge cranes, 갠트리 크레인 휠, jib cranes in steel mills, metallurgical plants, and foundries

- 2. Container cranes, portal cranes in ports, docks, and logistics yards

- 3. Overhead crane wheel, electric hoists in warehouses, 워크샵, 건설 현장

- 4. Special cranes for heavy machinery manufacturing, 발전소, and chemical industries

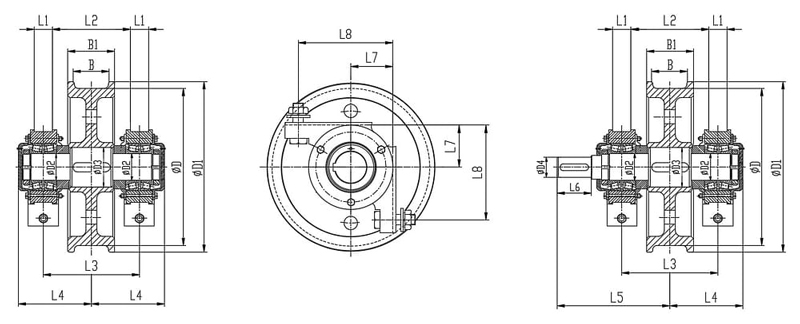

Forged Crane Wheels Technical Parameters

|

매개 변수

|

사양

|

|

재료

|

42CRMO, 60Si2Mn, 45# 강철, 등. (사용자 정의 가능)

|

|

Diameter Range

|

Φ200mm – Φ1500mm (customizable according to customer needs)

|

|

표면 경도

|

HRC 45-55

|

|

Load-Bearing Capacity

|

5t – 500t (depending on material and size)

|

|

Surface Roughness

|

Ra ≤ 1.6μm

|

|

열처리

|

담금질 + 템퍼링

|

Forged Crane Wheels Quality Assurance

We adhere to the principle of “quality first” and have established a complete quality management system certified by ISO9001. Each forged crane wheel undergoes strict testing before leaving the factory, 포함:

- 1. Raw material chemical composition analysis and mechanical property testing

- 2. 비파괴 테스트 (ndt) such as ultrasonic testing and magnetic particle testing to detect internal and surface defects

- 3. Hardness testing and metallographic structure analysis

- 4. Dimensional accuracy inspection using precision measuring instruments (such as coordinate measuring machines)

We also provide customized services according to customers’ specific requirements, including size, 재료, heat treatment process, and surface treatment. Our professional technical team will work closely with you to provide the most suitable forged crane wheel solutions.

If you are looking for reliable, high-performance forged crane wheels, 오늘 저희에게 연락해주세요. We are committed to providing you with excellent products and professional services!

PDF로 공유: 다운로드

최신 의견