크레인은 현대 산업의 일꾼입니다., 리프팅에 꼭 필요한, 움직이는, 정밀하고 효율적으로 무거운 하중을 포지셔닝합니다.. 제조 현장부터 분주한 항만, 대규모 건설 현장까지, 다양한 유형의 크레인이 특정 작업 및 환경에 맞게 설계되었습니다.. 이러한 변화를 이해하는 것이 작업에 적합한 장비를 선택하는 데 중요합니다.. 이 가이드에서는 산업용 및 물류용 크레인의 주요 유형을 살펴봅니다., 그들의 독특한 특징, 및 주요 응용 프로그램.

오버헤드 크레인은 공장 어디에나 존재합니다., 창고, 그리고 워크샵. 수평 빔을 따라 움직이는 호이스트로 구성됩니다. (다리), 건물 길이를 따라 높은 활주로를 따라 자체적으로 이동합니다..

단일 대들보 오버헤드 크레인

이중 대들보 오버헤드 크레인

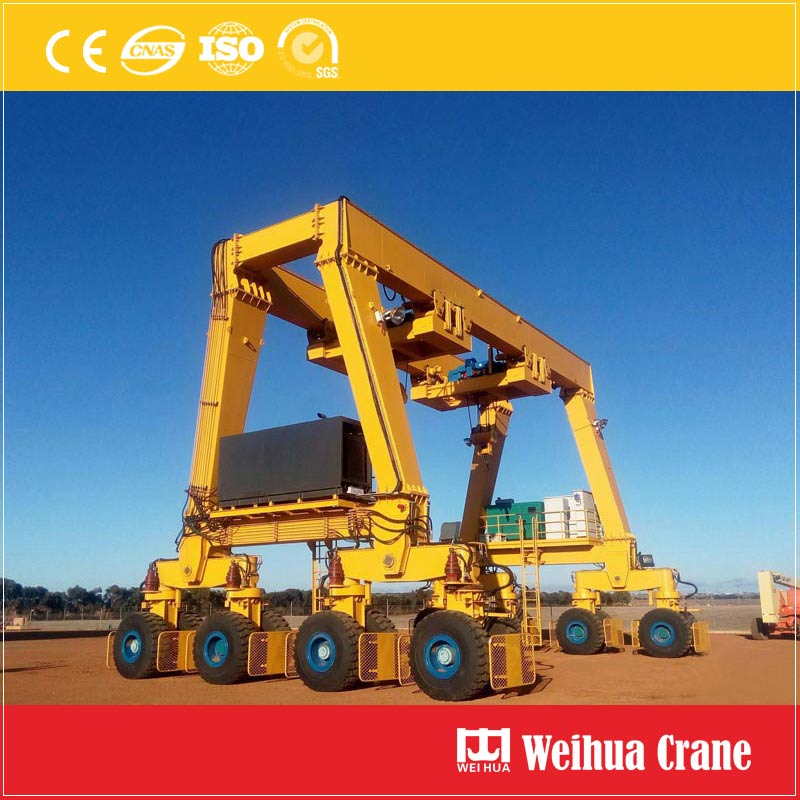

갠트리 크레인은 오버헤드 크레인과 유사하지만 지면을 따라 바퀴나 레일로 움직이는 독립형 다리로 지지됩니다., 건물의 지붕 구조가 필요하지 않음. 그들은 실내 및 실외 사용 모두에 매우 다재다능합니다..

고무로 지친 갠트리 (RTG) 기중기

고무로 지친 갠트리 (RTG) 기중기: 컨테이너 터미널에 주로 사용되는 이동식 갠트리 크레인. 고무타이어로 달린다, 야드 작업에서 컨테이너를 쌓을 때 유연성이 뛰어납니다..

레일 장착형 갠트리 (RMG) 기중기

레일 장착형 갠트리 (RMG) 기중기: RTG와 유사하지만 고정 레일 트랙에서 실행됩니다.. 이를 통해 보다 정확한 위치 지정이 가능합니다., 더 높은 스태킹 능력, 자동화된 작업에 더 적합합니다..

이들은 선박의 신속한 적재 및 하역을 위해 특별히 설계된 대형 거인입니다..

선박에서 해안으로 (STS) 기중기

선박에서 해안으로 (STS) 기중기 / 컨테이너 갠트리 크레인: 이것들은 상징적이다, 컨테이너 터미널에 보이는 거대 크레인. 그들은 정박한 배에 걸터앉아 있다, 선박과 부두 사이에서 직접 컨테이너 이동. 현대 컨테이너 운송에 필수적입니다..

컨테이너 갠트리 크레인

모바일 하버 크레인: 다재다능한, 다양한 작업을 수행할 수 있는 바퀴형 또는 레일 장착형 크레인, 컨테이너 취급을 포함하여, 대량 재료, 일반화물. 다목적 포트에 뛰어난 유연성을 제공합니다..

흔히 "골리앗" 크레인이라고 불립니다., 이것들은 무겁다, 대형 리프트에 사용되는 대용량 갠트리 크레인.

Q1: 공장 내에서 가장 일반적인 유형의 크레인은 무엇입니까??

에이: 오버헤드 브리지 크레인이 가장 일반적입니다., 가벼운 작업을 위한 싱글 거더 크레인과 무거운 작업을 위한 더블 거더 크레인.

Q2: RTG와 RMG의 주요 차이점은 무엇입니까?

에이: RTG (고무로 지친 갠트리) 이동성이 있고 유연하다, 마당에서 자유롭게 이동. RMG (레일 장착형 갠트리) 고정된 트랙에서 달리다, 더 높은 정밀도 제공, 더 높은 스택을 위한 안정성, 자동화하기가 더 쉽습니다..

Q3: 컨테이너 선박 하역을 위해 특별히 설계된 크레인은 무엇입니까??

에이: 선박에서 해안까지 (STS) 컨테이너 갠트리 크레인은 이러한 고속 작업을 위해 특별히 설계되었습니다., 대용량 작업.

Q4: 대형 선박을 건조하려면 어떤 유형의 크레인이 사용됩니까??

에이: 대규모 포털/갠트리 크레인 (종종 골리앗 또는 조선 갠트리라고 불림) 선박 선체 및 상부 구조의 조립식 대형 부분을 들어 올리고 위치를 지정하는 데 사용됩니다..

Q5: 올바른 유형의 크레인을 선택하는 방법?

에이: 주요 요인은 다음과 같습니다: 화물의 무게와 크기, 필요한 스팬 및 리프팅 높이, 듀티 사이클 (사용빈도), 사용 가능한 공간 (실내/실외), 이동성 요구, 그리고 예산. 항상 크레인 전문가와의 상담을 권장합니다.

작업장 오버헤드 크레인의 정밀도부터 항만 STS 크레인의 원동력까지, 각 유형의 크레인은 글로벌 산업 및 인프라에서 중요한 역할을 합니다.. 다용도 갠트리인지 여부에 관계없이 올바른 크레인 선택, 전문 컨테이너 핸들러, 또는 무거운 리프트 포털 크레인은 안전을 달성하는 데 필수적입니다., 능률, 모든 자재 취급 작업의 생산성.

우리는 귀하의 의견을 소중히 여깁니다! 귀하의 특정 요구에 맞게 서비스를 조정할 수 있도록 아래 양식을 작성하십시오..

최신 의견