Overhead cranes are indispensable workhorses in manufacturing plants, 창고, 건설 현장, relied upon for lifting and moving heavy loads efficiently. 하지만, 오버헤드 크레인 정전 is a common and frustrating issue that can bring operations to a grinding halt, leading to costly downtime, delayed projects, and even safety risks. Understanding the root causes of these power outages and having a clear troubleshooting process is essential for minimizing disruptions and ensuring workplace safety. 이 블로그에서는, we’ll dive into the main reasons behind overhead crane power failures and provide a step-by-step guide to resolving them effectively.

To solve a power failure, it’s first crucial to identify its source. Overhead crane power issues typically stem from three core areas: electrical system malfunctions, 환경적 요인, and operational errors.

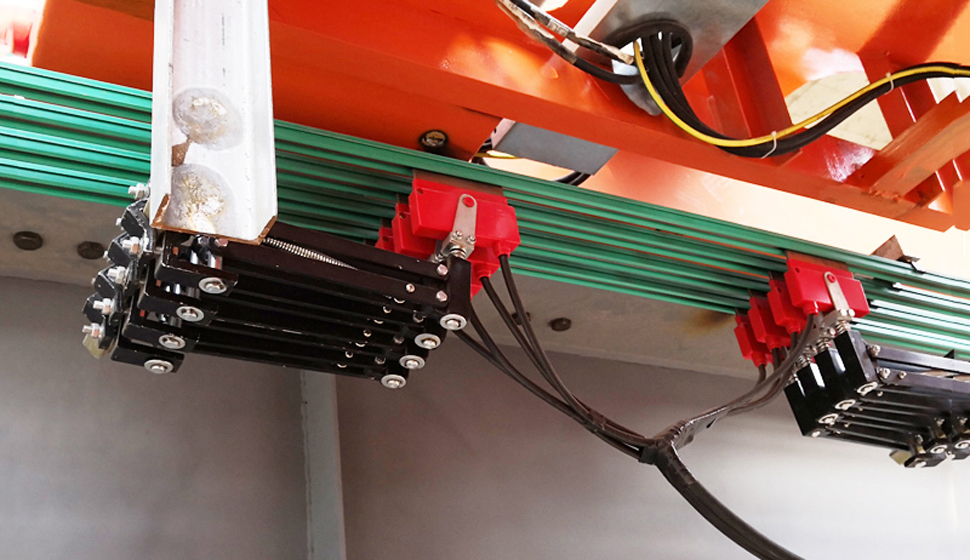

The electrical system is the lifeline of an overhead crane, and any fault within it can trigger a power outage. One of the most frequent culprits is damaged power cables or conductors. 시간이 지남에 따라, the cables that supply power to the crane (such as festoon cables or trailing cables) can wear out due to constant movement, friction against the crane structure, or exposure to heavy loads. 균열, 닳아 해어짐, or breaks in the insulation can cause short circuits or complete power loss. 추가적으로, loose or corroded electrical connections—including terminals, 커넥터, and junction boxes—can disrupt the flow of electricity. Corrosion often occurs due to moisture ingress, while loose connections may result from vibration during crane operation.

Another common electrical issue is faulty control panels or components. The crane’s control panel houses circuit breakers, 접촉기, relays, and fuses, all of which are prone to wear and tear. A tripped circuit breaker (caused by overloads or short circuits) or a blown fuse can cut off power instantly. Contactors and relays, which regulate the flow of electricity to the crane’s motors, may fail due to overheating, dust accumulation, or mechanical wear.

Harsh working environments can significantly impact the reliability of 오버헤드 크레인 power systems. Extreme temperatures—whether scorching heat or freezing cold—can degrade electrical components. High temperatures may cause insulation to melt, while low temperatures can make cables brittle and prone to cracking. Humidity and moisture are also major threats: when water seeps into electrical enclosures, 제어판, or cable connections, it can cause short circuits, 부식, or rust on metal parts, leading to power failures.

먼지, 부스러기, and industrial pollutants are another environmental hazard. In factories or construction sites with high levels of dust, particles can accumulate on circuit boards, 접촉기, and other electrical components, interfering with their functionality. For outdoor cranes, inclement weather such as rain, 눈, lightning, or strong winds can damage power lines, 케이블, or electrical enclosures, resulting in sudden power outages.

Human error and poor maintenance practices are often overlooked causes of overhead crane power failure. Overloading the crane beyond its rated capacity is a common operational mistake: excessive weight strains the crane’s motors and electrical system, leading to overheating, tripped circuit breakers, or even permanent damage to components. Improper operation, such as abrupt starts, stops, or changes in direction, can also cause voltage spikes that disrupt the power supply.

Neglecting regular maintenance is equally problematic. Failing to inspect cables, 사이, and electrical components for wear, 부식, or damage allows small issues to escalate into major power failures. 예를 들어, if a frayed cable is not replaced promptly, it may eventually break, cutting off power mid-operation. Similarly, skipping routine cleaning of control panels and electrical enclosures allows dust and debris to build up, increasing the risk of short circuits.

When an overhead crane experiences a power failure, it’s important to act quickly but safely. Follow this structured troubleshooting process to identify and resolve the issue:

Before attempting any troubleshooting, prioritize safety to prevent accidents or further damage. Stop all crane operations immediately and secure the load (if possible) to avoid it falling. Turn off the main power switch to the crane and lock it out (using a lockout-tagout procedure) to prevent accidental reconnection while working. Wear appropriate personal protective equipment (PPE), such as insulated gloves, 안전 안경, and non-slip shoes, to protect against electrical shocks or falling debris. If the crane is outdoors and weather conditions are hazardous (예를 들어, lightning, heavy rain), wait until the weather clears before inspecting.

Start with a basic visual check to identify obvious issues. Inspect the power cables and conductors (festoon cables, trailing cables, and power lines) for signs of damage—fraying, 균열, breaks, or exposed wires. Check cable connections at the crane, power source, and junction boxes for looseness, 부식, or burning marks (which indicate a short circuit). Examine the control panel for tripped circuit breakers, blown fuses, or visible damage such as melted insulation or smoke residue. 또한, check the crane’s motors and electrical enclosures for signs of overheating, 수분, or dust accumulation.

If the visual inspection doesn’t reveal the issue, verify that the crane is receiving power from the source. Use a multimeter to check the voltage at the main power input to the crane—ensure it matches the crane’s rated voltage (예를 들어, 220다섯, 380다섯). If there’s no voltage, the problem may lie with the external power supply, such as a tripped main circuit breaker in the building, a damaged power line, or a fault in the electrical grid. Contact the facility’s electrical team to resolve external power issues. If the voltage is too low or fluctuating, this may indicate a problem with the power source or a loose connection in the main wiring.

If the power source is functioning correctly, focus on the crane’s control panel. Reset any tripped circuit breakers and replace blown fuses with ones of the correct rating (never use a higher-rated fuse, as this can cause overheating and fire hazards). Check contactors and relays for signs of wear, such as pitted contacts or broken springs. Use a multimeter to test if these components are receiving and transmitting power properly—if a contactor fails to engage, it may need to be cleaned, repaired, or replaced. 또한, clean the control panel of dust and debris using a dry cloth or compressed air (ensure the power is off before cleaning).

Loose or damaged cables are often the root cause of power failures. Tighten any loose connections using the appropriate tools (avoid over-tightening, as this can damage terminals). If cables are frayed, cracked, or broken, replace them immediately with cables of the same specifications (계량기, insulation type) to ensure compatibility and safety. For festoon cables, check the trolley system to ensure cables are not getting caught or pinched during movement—adjust the cable support system if necessary.

If the power failure was caused by environmental factors, take corrective action to prevent recurrence. 예를 들어, if moisture entered the control panel, dry it thoroughly and install waterproof enclosures or seals. If extreme temperatures are an issue, consider adding cooling or heating systems for electrical components. For operational errors, retrain operators on proper crane use—emphasize avoiding overloading, abrupt movements, and following load capacity guidelines.

After resolving the issue, turn on the main power switch (remove lockout-tagout) and conduct a test run. Operate the crane at low speed, testing all functions (리프팅, 저하, moving left/right) to ensure power is consistent and there are no unusual noises or vibrations. Monitor the electrical system for overheating during the test run—if issues persist, repeat the troubleshooting process or contact a professional technician.

Overhead crane power failure can be disruptive, but with a clear understanding of the causes and a structured troubleshooting process, you can resolve issues quickly and safely. Regular maintenance—including inspecting cables, 사이, and electrical components, cleaning control panels, and training operators—is key to preventing power failures in the first place. By prioritizing safety, conducting thorough inspections, and addressing issues promptly, you can minimize downtime, protect your equipment, 원활한 작동을 보장합니다. If you’re unsure about any step in the troubleshooting process, don’t hesitate to consult a qualified electrical technician or crane maintenance expert.

우리는 귀하의 의견을 소중히 여깁니다! 귀하의 특정 요구에 맞게 서비스를 조정할 수 있도록 아래 양식을 작성하십시오..

최신 의견