크레인 후크가 붙어 있습니까?, 매끄럽게 회전하는 것을 거부합니다? A crane hook that won’t rotate is more than just an annoyance—it’s a major safety hazard and a significant productivity killer. It can cause load instability, uneven stress on the sling, and even dangerous accidents.

If you’re searching for a fix for a “crane hook not rotating,” you’ve come to the right place. This guide will walk you through the most common causes and provide practical, step-by-step solutions to get your hook moving freely again and ensure safe operation.

A freely rotating hook is essential for proper rigging. It allows the load to self-center, prevents slings from twisting and kinking, and ensures the load is balanced. A seized hook forces the wire rope or chain to twist instead, leading to accelerated wear, 손상, and potential failure.

1. Lack of Lubrication (The Most Common Cause)

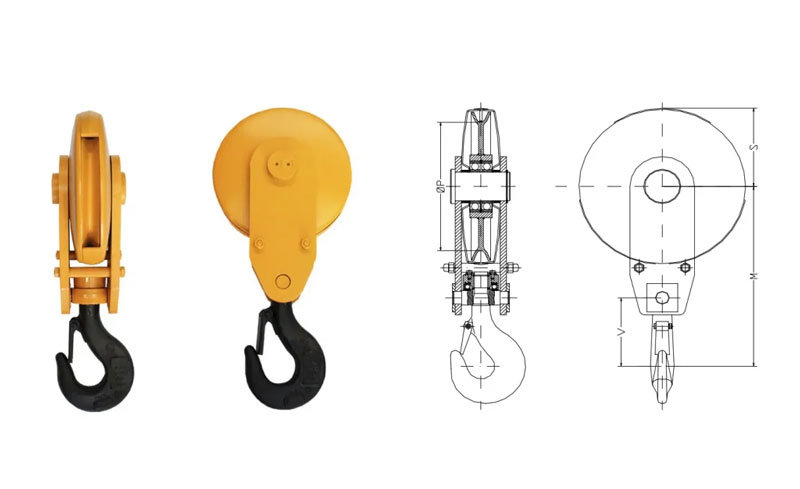

The swivel mechanism (bearings or bushing) inside the hook requires regular lubrication to function smoothly. 시간이 지남에 따라, grease hardens, collects dirt, and washes away, leading to increased friction and eventual seizing.

2. Dirt, Debris, and Contamination

Construction and industrial sites are dirty environments. 먼지, grit, concrete splatter, and metal filings can work their way into the swivel assembly, acting as an abrasive paste that grinds down components and prevents movement.

3. Corrosion and Rust

습기에 노출, 비, or humid conditions can cause the internal components of the swivel to rust and corrode. This bonds the moving parts together, effectively welding them in place.

4. Mechanical Damage (Bent Hook or Damaged Swivel)

A direct impact from a dropped load or snagging can physically damage the hook or its swivel assembly. A bent hook or deformed throat will not rotate correctly.

5. Overloading and Bearing Failure

Exceeding the Working Load Limit (wll) of the hook can cause catastrophic internal damage. It can crack the hook, collapse the bearing races, or deform internal components, leading to a complete and sudden seizure.

6. Improper Storage or Lack of Use

A hook that sits idle for long periods, especially outdoors, is prone to seizing up for all the reasons listed above—lubricant dries out, and corrosion sets in.

7. Worn-Out Swivel Bushing or Bearings

Like any mechanical component, the swivel mechanism has a finite lifespan. After years of use, bearings can wear out, become pitted, and lose their ability to turn smoothly.

Your number one priority is safety. Before any repair attempt, 다음 단계를 따르세요:

The best fix for a “crane hook not rotating” is to prevent it from happening in the first place.

A non-rotating crane hook is a clear sign that maintenance is overdue or that damage has occurred. By understanding these common causes—from simple lack of lubrication to serious mechanical damage—you can diagnose the issue and apply the correct fix. 기억하다, when in doubt, always err on the side of caution and consult a qualified crane technician. Keep your hooks moving freely to ensure a safe and efficient worksite.

우리는 귀하의 의견을 소중히 여깁니다! 귀하의 특정 요구에 맞게 서비스를 조정할 수 있도록 아래 양식을 작성하십시오..

최신 의견