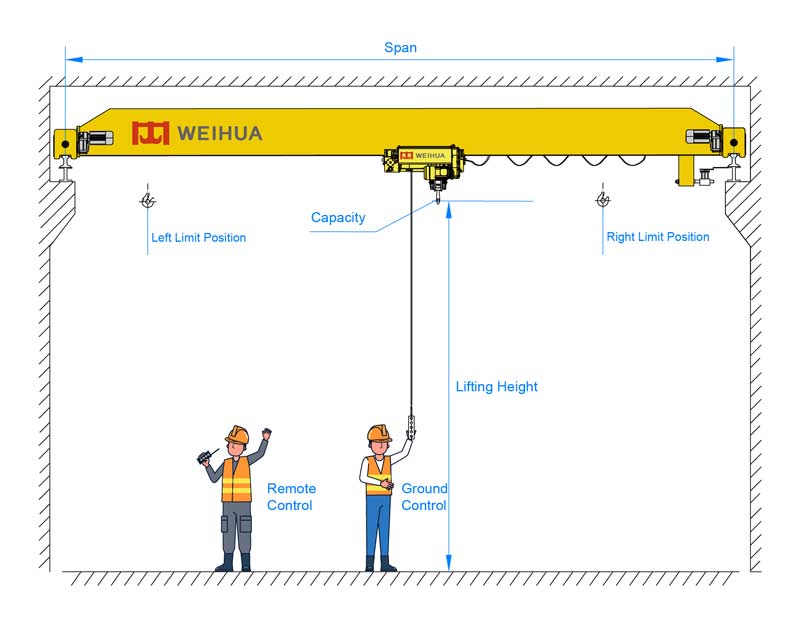

Warehouse overhead cranes, also known as bridge cranes, are essential material handling equipment widely used in warehouse environments. They are designed to lift, 動く, and position heavy loads horizontally within the warehouse space.

Warehouse Single Girder Overhead Cranes

It has a single main beam structure, コンパクトなデザイン, and light dead weight. The lifting capacity is usually 0.5-20 トン, and the span is 7.5-31.5 メーター. It is suitable for warehouses with small to medium lifting requirements, such as light industry workshops, logistics distribution centers, and small parts storage warehouses, where the operation frequency is not too high.

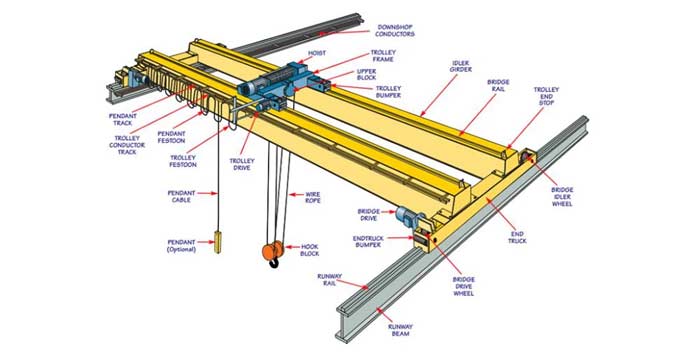

Warehouse Double Girder Overhead Cranes

Equipped with two parallel main beams, it has stronger load-bearing capacity and stability than single girder cranes. The lifting capacity can reach 5-500 トン, and the span is 10-40 メーター. It is widely used in heavy industry warehouses, machinery manufacturing workshops, and large-scale logistics warehouses that need to lift heavy equipment, 金型, or bulk materials.

Warehouse Low Headroom Overhead Crane

Designed with a special structure to reduce the headroom (the distance from the top of the crane to the top of the warehouse). It is suitable for warehouses with limited vertical space, such as old warehouses or buildings with low ceiling heights, ensuring maximum utilization of the available lifting height.

A general term for electric-driven overhead cranes, which can be single-girder or double-girder. It uses electric motors for lifting and traveling, with stable operation and high efficiency. It is the most common type of crane in various warehouses, applicable to most material handling scenarios, including loading/unloading, transfer, and stacking.

Its main beam is suspended from the roof truss or special track of the warehouse, without occupying the ground or column space. It is suitable for warehouses with complex ground layouts, such as workshops with many production equipment on the ground, or places where the ground needs to be kept unobstructed for other operations.

防爆天井クレーン

Made of explosion-proof components and materials, it can prevent sparks and static electricity during operation. It is specially used in warehouses storing flammable, explosive, or corrosive materials, such as chemical warehouses, oil storage depots, and pharmaceutical workshops with explosive environments.

Warehouse overhead cranes, also known as bridge cranes, are essential material handling equipment widely used in warehouse environments. They are designed to lift, 動く, and position heavy loads horizontally within the warehouse space. These warehouse overhead cranes operate on an overhead runway system consisting of rails mounted on the warehouse ceiling or support columns, allowing them to cover a large working area without occupying valuable floor space. Warehouse overhead cranes play a crucial role in various warehouse operations such as loading and unloading goods from trucks, transferring materials between different storage areas, stacking heavy items on high shelves, and assisting in the assembly or maintenance of equipment within the warehouse. Their ability to handle heavy loads efficiently makes them indispensable for improving productivity and streamlining material flow in warehouses of all sizes, from small distribution centers to large industrial warehouses.

|

モデル

|

定格吊り上げ能力 (t)

|

スパン (m)

|

高さを持ち上げる (m)

|

労働者階級

|

持ち上げ速度 (私/私)

|

Running Speed (私/私)

|

電源

|

|---|---|---|---|---|---|---|---|

|

QD-5

|

5

|

10-30

|

6-18

|

A3-A5

|

8-16

|

20-40

|

380V/50Hz/3相

|

|

QD-10

|

10

|

10-35

|

6-20

|

A4-A6

|

5-12

|

15-30

|

380V/50Hz/3相

|

|

QD-20

|

20

|

12-40

|

8-22

|

A5-A7

|

3-10

|

10-25

|

380V/50Hz/3相

|

|

Customized

|

According to customer needs

|

According to customer needs

|

According to customer needs

|

According to customer needs

|

According to customer needs

|

According to customer needs

|

According to customer needs

|

The price of warehouse overhead cranes is closely related to various equipment parameters, as different parameter configurations will directly affect the production cost and performance of the crane. Key parameters that influence the price include the rated lifting capacity (the higher the capacity, the higher the corresponding cost due to stronger structural requirements and more powerful components), スパン (longer spans require more robust bridge structures and runway systems), 持ち上げ高さ (greater heights need longer lifting mechanisms and enhanced safety protections), working class (higher working classes demand more durable components to withstand frequent use), control method (advanced control systems like remote or cabin control may increase costs compared to basic pendant control), and additional customized accessories (such as special hooks, anti-sway devices, or monitoring systems). These parameters interact to determine the final price of the warehouse overhead crane.

For customized warehouse overhead cranes, the price will be accurately calculated based on the specific parameter requirements provided by the customer, such as the exact rated lifting capacity, スパン, 持ち上げ高さ, and any special functional additions. We are committed to offering cost-effective solutions that match the performance needs of our customers. After understanding your detailed parameter demands, our professional sales team will provide a tailored quotation plan that clearly reflects the correlation between each parameter and the corresponding cost component.

Q1: What safety devices are equipped with the warehouse overhead crane?

a: Our warehouse overhead cranes are equipped with multiple safety devices, 過負荷保護を含む, リミットスイッチ (upper and lower limit for lifting, left and right limit for running), 非常停止ボタン, 衝突防止装置, および電圧損失保護. These devices effectively ensure the safety of personnel and equipment during operation.

Q2: Do I need professional personnel to install the warehouse overhead crane?

a: はい, the installation of warehouse overhead cranes requires professional technical personnel. Our company provides professional installation teams with rich experience. They will carry out on-site installation, デバッグ, and acceptance in strict accordance with relevant standards and safety regulations to ensure the crane is installed correctly and can operate safely.

Q3: What is the maintenance cycle of the warehouse overhead crane?

a: The maintenance cycle includes daily maintenance, weekly maintenance, monthly maintenance, and annual maintenance. Daily maintenance mainly involves checking the safety devices, 潤滑, and appearance of the crane; weekly maintenance focuses on inspecting the mechanical components and electrical systems; monthly maintenance includes more in-depth inspections and adjustments; annual maintenance is a comprehensive overhaul of the entire crane. Specific maintenance content and cycles can refer to the product manual or consult our after-sales service team.

Q4: Can the warehouse overhead crane be customized according to the size of my warehouse?

a: はい, we provide customized services. We can design and manufacture cranes with appropriate span, 持ち上げ高さ, and other parameters according to the actual size of your warehouse, the layout of support columns, and your material handling needs to ensure the crane can be perfectly adapted to your warehouse environment.

Q5: How long is the warranty period for the warehouse overhead crane?

a: Our warehouse overhead cranes have a standard warranty period of 12 months from the date of successful installation and acceptance. During the warranty period, if there are any quality problems caused by the product itself, we will provide free repair or replacement of parts. We also offer extended warranty services for customers who need it.

PDFで共有: ダウンロード

私たちはあなたのフィードバックを大切にします! あなたの特定のニーズに合わせてサービスを調整できるように、以下のフォームに記入してください.

Steel Coil Handling Overhead Crane For Sale Designed exclusively for the rigorous deman……

もっと発見してください →

最新のコメント