製品紹介

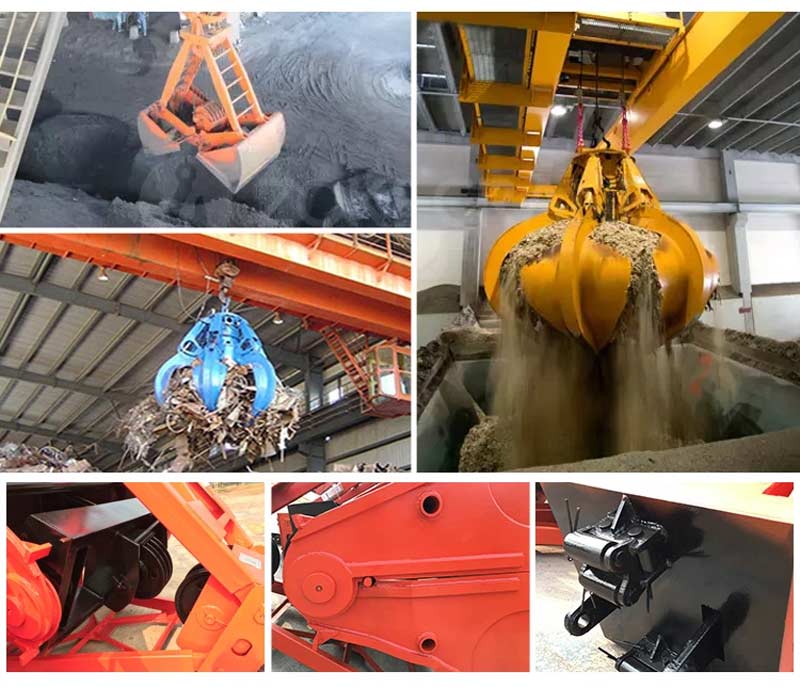

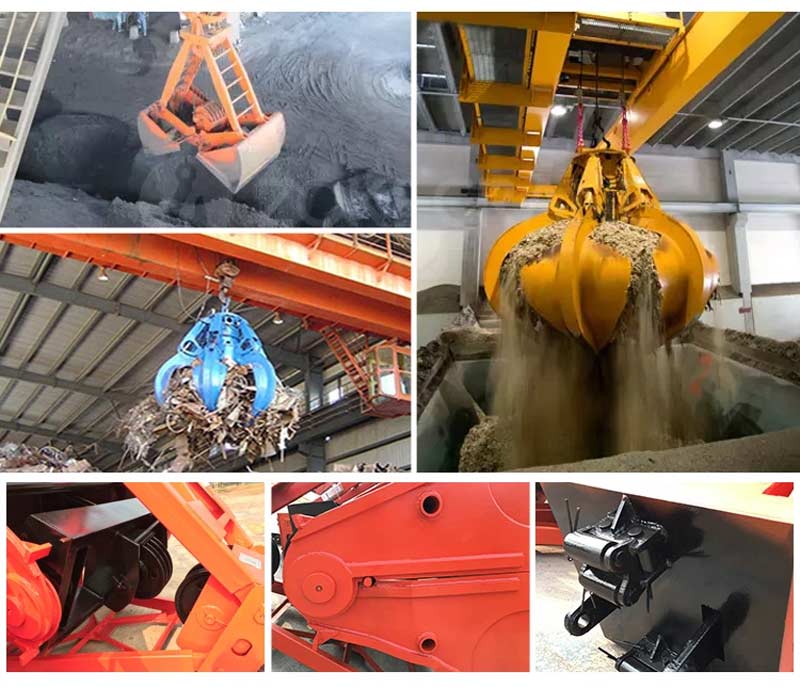

The double girder overhead crane with grab is a specialized material handling equipment designed for efficient grabbing, 持ち上げる, and transporting bulk materials. It integrates a sturdy double-girder bridge structure with a high-performance バケツをつかむ, making it an indispensable tool in industries that require large-scale and continuous bulk material handling. Unlike single girder overhead cranes, the double girder design provides superior load-bearing capacity, 安定性, and working range, enabling it to adapt to harsh working environments such as high temperature, ほこり, and heavy load. The grab bucket, as the core working component, is customized according to the characteristics of the handled materials (such as density, particle size, and corrosiveness), ensuring reliable grabbing and unloading operations. This crane is widely recognized for its high efficiency, 安全性, そして耐久性, and is widely used in ports, 製鉄所, 発電所, mines, garbage treatment plants, and other fields.

Double Girder Overhead Crane With Grab Features

- 1. Strong Load-Bearing Capacity: The double girder structure adopts high-quality steel plates and optimized welding technology, which effectively improves the overall rigidity and load-bearing capacity of the crane. It can bear larger lifting weights (いつもの 5-32 トン) and has excellent resistance to deformation, ensuring stable operation under heavy load conditions.

- 2. Efficient Grab Operation: Equipped with a high-performance grab bucket (mechanical or hydraulic type), it can quickly grab, リフト, and unload bulk materials such as coal, 鉱石, 粒, and garbage. The grab opening and closing speed is adjustable, and the grabbing force is strong, which greatly improves the material handling efficiency.

- 3. Stable and Reliable Performance: The crane is equipped with high-precision lifting and traveling mechanisms, adopting famous brand motors, 減速機, そしてブレーキ. The transmission is smooth, the operation is stable, and the failure rate is low. It can work continuously for a long time under severe working conditions.

- 4. Flexible and Convenient Operation: It supports multiple operation modes such as ground operation (button station), remote control operation, and cab operation. The operation interface is simple and intuitive, and the operator can easily control the crane’s lifting, traveling, and grab opening and closing actions, reducing the labor intensity of the operator.

- 5. 総合的な安全保護: The crane is equipped with a complete set of safety protection devices, 過負荷保護を含む, over-lifting protection, リミットスイッチ (持ち上げ高さ制限, 走行制限), 非常停止ボタン, そして衝突防止装置. These devices can effectively prevent operational errors and equipment failures, ensuring the safety of operators and equipment.

- 6. 簡単なメンテナンス: The structural design of the crane is reasonable, and the key components (モーターなどの, 減速機, and bearings) are easy to disassemble and maintain. The surface of the crane is treated with anti-corrosion coating, which improves the anti-corrosion performance and extends the service life of the equipment.

Double Girder Overhead Crane With Grab Technical Parameters

|

パラメータ名

|

仕様範囲

|

|

定格吊り上げ能力

|

5 - 32 T

|

|

スパン

|

10 - 40 m (customizable according to user needs)

|

|

高さを持ち上げる

|

6 - 34 m (customizable according to user needs)

|

|

持ち上げ速度

|

0.5 - 10 私/私 (variable frequency speed regulation optional)

|

|

走行速度 (クレーン)

|

10 - 40 私/私

|

|

走行速度 (トロリー)

|

5 - 20 私/私

|

|

労働者階級

|

A5~A8 (GB/Tによると 3811-2008)

|

|

電源

|

380V/50Hz (customizable for different voltage and frequency)

|

|

Grab Type

|

Mechanical grab, hydraulic grab (customizable according to material characteristics)

|

Double Girder Overhead Crane With Grab Composition Structure

The double girder overhead crane with grab is composed of six main parts: bridge structure, trolley assembly, grab device, 昇降機構, traveling mechanism, および電気制御システム. Each part cooperates closely to ensure the stable and efficient operation of the crane.

- 1. Bridge Structure: It is the main load-bearing part of the crane, consisting of two main girders, two end girders, and connecting beams. The main girders are usually made of box-shaped section steel, which has high rigidity and strength. The end girders are connected to the main girders by welding or bolts, and are equipped with traveling wheels to realize the movement of the crane along the track.

- 2. トロリーアセンブリ: Installed on the track of the main girders, it can move horizontally along the main girders. The trolley assembly includes a trolley frame, 昇降機構, およびトロリー走行機構. It is the core part that drives the grab bucket to lift and move horizontally.

- 3. Grab Device: As the working component that directly contacts the materials, it is composed of a grab bucket, connecting rod, and driving mechanism. According to the driving mode, it can be divided into mechanical grab and hydraulic grab. The mechanical grab is driven by the steel wire rope of the lifting mechanism to realize opening and closing; the hydraulic grab is driven by a hydraulic system, which has stronger grabbing force and is suitable for handling high-density and large-particle materials.

- 4. 昇降機構: Installed on the trolley frame, it consists of a motor, reducer, brake, ドラム, and steel wire rope. It is used to drive the grab bucket to lift and lower. The motor drives the drum to rotate through the reducer, and the steel wire rope winds around the drum to drive the grab bucket to move up and down. The brake is used to stop the grab bucket at any position to ensure safety.

- 5. Traveling Mechanism: It includes the crane traveling mechanism and the trolley traveling mechanism. Both are composed of motors, 減速機, ブレーキ, and traveling wheels. The crane traveling mechanism drives the entire crane to move along the factory building track; the trolley traveling mechanism drives the trolley to move along the main girder track, realizing the full-range coverage of the working area.

- 6. 電気制御システム: 鶴の「頭脳」です, consisting of a control cabinet, operation device (button station, リモコン, cab), contactor, 周波数変換器, and various sensors. It is used to control the start, stop, speed regulation, and safety protection of the crane. The frequency converter can realize the stepless speed regulation of the lifting and traveling mechanisms, making the operation more stable and energy-saving.

Double Girder Overhead Crane With Grab Industry Applications

Due to its excellent performance in bulk material handling, the double girder overhead crane with grab is widely used in various industries that involve bulk material loading, 荷降ろし, and transportation. The specific application fields are as follows:

- 1. Port and Wharf: Used for loading and unloading bulk materials such as coal, 鉱石, 粒, and fertilizer on ships and trucks. It can efficiently complete the transfer of bulk materials between ships, 倉庫, and transportation vehicles, improving the loading and unloading efficiency of the port.

- 2. Steel Mill: Used for handling raw materials (such as iron ore, coking coal) そして完成品 (such as steel billets, スチールプレート) in the steel production process. It can adapt to the high-temperature, dusty working environment in the steel mill, and realize the continuous and stable transportation of materials.

- 3. Power Plant: Used for loading and unloading coal in the coal yard of the power plant. It can grab coal from the coal pile and transport it to the coal feeder, ensuring the continuous supply of fuel for the boiler, which is an important equipment for the normal operation of the power plant.

- 4. Mine: Used for handling ore, 石炭, and other minerals in the mine. It can transport the mined minerals from the underground or open-pit mine to the storage yard or transportation equipment, improving the mining efficiency.

- 5. Garbage Treatment Plant: Used for grabbing and transporting garbage in the garbage transfer station and incineration plant. It can realize the classification, transfer, and loading of garbage, and is an important equipment for environmental protection projects.

- 6. Cement Plant and Chemical Plant: Used for handling raw materials (such as limestone, clay) そして完成品 (such as cement, chemical fertilizers) in the production process. It can adapt to the corrosive and dusty working environment in chemical plants and ensure the smooth progress of the production process.

Types of Grabs for Overhead Cranes

The grab is a key component of the double girder overhead crane with grab, and its type is selected according to the characteristics of the handled materials and the working environment. Common types of grabs for overhead cranes are as follows:

- Mechanical Grab: It is the most commonly used type of grab, which is driven by the steel wire rope of the crane’s lifting mechanism to realize opening and closing. According to the number of steel wire ropes, it can be divided into single-rope grab, double-rope grab, and four-rope grab. The single-rope grab has a simple structure and low cost, but its grabbing force is small, suitable for handling light bulk materials; the double-rope grab and four-rope grab have larger grabbing force and higher work efficiency, suitable for handling heavy and high-density bulk materials such as ore and coal. The mechanical grab has the advantages of simple maintenance, low failure rate, and strong adaptability to the working environment.

- Hydraulic Grab: It is driven by a hydraulic system, which consists of a hydraulic pump, hydraulic cylinder, control valve, and oil tank. The hydraulic cylinder drives the jaw plate of the grab to open and close. Compared with the mechanical grab, the hydraulic grab has stronger grabbing force, more stable operation, and can realize stepless speed regulation of opening and closing. It is suitable for handling high-density, large-particle, and viscous materials such as rock, sludge, and garbage. しかし, the hydraulic grab has higher requirements for the working environment, and the hydraulic system needs regular maintenance to prevent oil leakage.

- Special Grab: According to the special needs of different industries, there are also various special grabs, のような:

- 1. Log Grab: Used for handling logs, with arc-shaped jaw plates to prevent the logs from slipping.

- 2. Scrap Grab: Used for handling scrap steel, with serrated jaw plates to enhance the grabbing force.

- 3. Grain Grab: Used for handling grain, with a mesh structure on the jaw plates to prevent grain leakage.

- 4. Corrosive Material Grab: Made of corrosion-resistant materials (such as stainless steel), used for handling corrosive materials such as chemicals and seawater-soaked materials.

PDFで共有: ダウンロード

最新のコメント