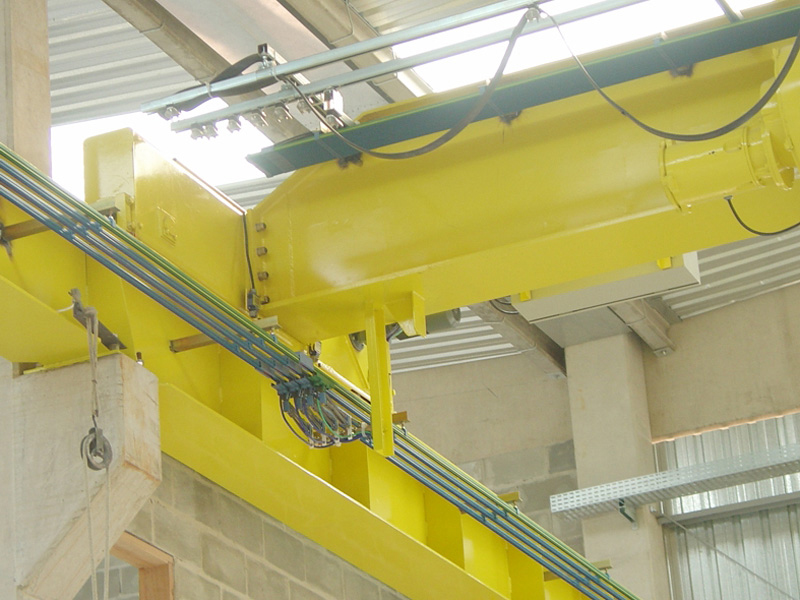

天井クレーン導体レールシステム, also known as a busbar or electrified rail system, is a robust and highly efficient method for delivering electrical power to overhead cranes, ホイスト, and other moving equipment within an industrial facility.

天井クレーン導体レールシステム, also known as a busbar or electrified rail system, is a robust and highly efficient method for delivering electrical power to overhead cranes, ホイスト, and other moving equipment within an industrial facility. Unlike traditional and less reliable systems like festoon cables or reeling drums, the conductor rail utilizes a solid, enclosed rail with integrated conductors. A collector trolley, attached to the moving crane, travels along the rail, making continuous sliding contact to draw power safely and reliably. This system is designed for heavy-duty applications where uptime, 安全性, and low maintenance are critical.

Conductor rail systems are primarily categorized based on their design and the type of current they carry. The main types include:

1. Rigid Conductor Rail Systems:

2. Flexible Conductor Rail Systems:

3. Cタイプ / Enclosed Conductor Rail Systems:

4. Safe-Line / Insulated Conductor Rail Systems:

The following table provides typical specifications for a standard rigid conductor rail system. Specifications can vary significantly by manufacturer and model.

| パラメーター | 典型的な範囲 / Options | 詳細 |

| Rated Current | 100a, 160a, 250a, 400a, 630a, 800A+ | Maximum continuous current capacity per phase. |

| Rated Voltage | Up to 690V AC / 1000DCで | Standard industrial voltage ratings. |

| Conductor Material | Copper, Aluminum | Copper offers better conductivity; aluminum is lighter and more cost-effective. |

| Housing Material | Galvanized Steel, Aluminum Alloy | Provides structural strength and corrosion resistance. |

| 保護クラス (IP) | IP23, IP54, IP65, IP68 | IP54 is common for indoor/outdoor use; IP65/68 for harsh/washdown environments. |

| 温度範囲 | -35°C ~ +85°C | Suitable for most industrial and cold storage environments. |

| Number of Poles | 3P + PE, 4P + PE, or custom | 3 段階 + Protective Earth is standard; additional poles for control circuits can be added. |

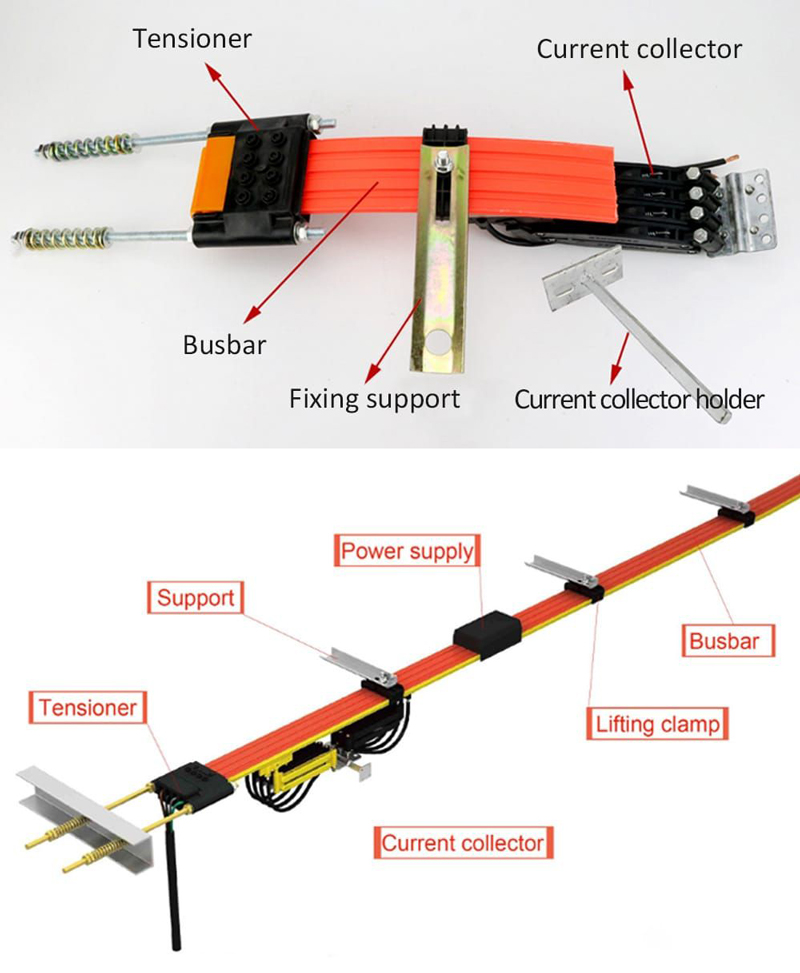

current collector

Overhead crane conductor rail systems are the preferred power solution in a wide range of industries:

By choosing a conductor rail system, you invest in a powerful, 安全, and reliable backbone for your material handling operations, maximizing productivity and minimizing total cost of ownership.

私たちはあなたのフィードバックを大切にします! あなたの特定のニーズに合わせてサービスを調整できるように、以下のフォームに記入してください.

レールマウントガントリークレーンとは? 風力発電用レール取り付け式ガントリークレーン レールm……

もっと発見してください →

What is an Electric Single Girder Crane? electric single girder crane with electric ho……

もっと発見してください →

最新のコメント