The Crane Wire Rope Drum is a mission-critical component designed for the safe and efficient spooling of wire rope on various types of cranes.

クレーンワイヤーロープドラムは吊り上げの核となり、, 場合によっては, the traversing mechanism, directly impacting the crane’s lifting capacity, operational smoothness, and overall safety. Manufactured from high-strength steel and engineered to precise specifications, our wire rope drums are built to withstand extreme loads, resist wear, and provide reliable service over a long operational lifespan in demanding industrial environments.

1. 堅牢な構造 & プレミアム材料

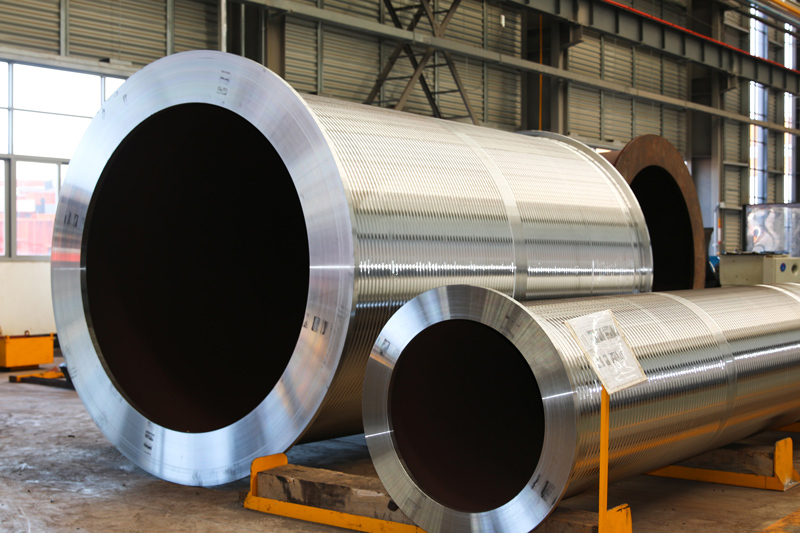

Fabricated from high-yield strength carbon steel or alloy steel forgings.

Designed with optimal wall thickness and structural integrity to handle maximum rated loads and prevent deformation.

2. Precision-Machined Grooves

The rope grooves are meticulously machined to match the specific diameter of the wire rope.

Ensures proper spooling, minimizes rope wear and crushing, and extends the service life of both the drum and the rope.

3. Advanced Flange Design

Flanges are engineered with sufficient height to contain multiple layers of rope safely, preventing rope override and potential accidents.

Rounded and smooth flange edges protect the wire rope from damage during operation.

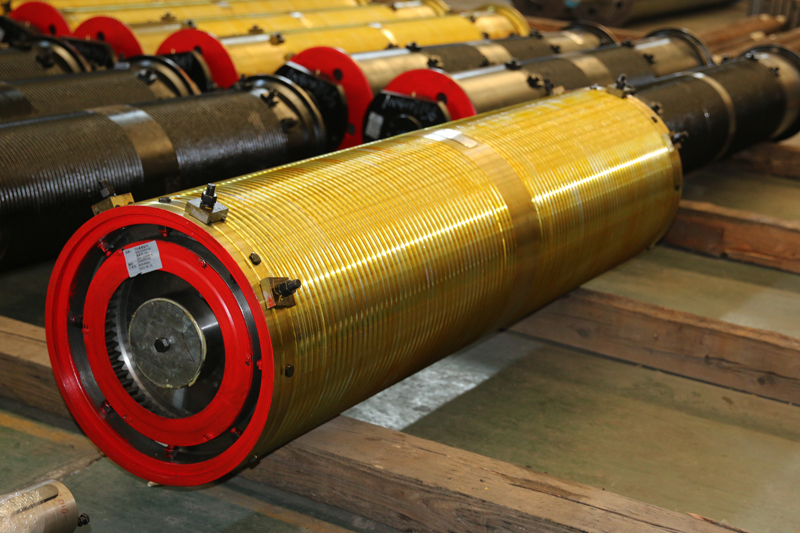

4. Durable Lifespan & 表面処理

Drums undergo specialized heat treatment processes (such as quenching and tempering) to enhance surface hardness and fatigue resistance.

Optional protective coatings like galvanization or specialized paint systems are available for superior corrosion resistance in harsh environments (例えば。, 海兵隊, 化学薬品).

5. Optimized Connection & 取り付け

Designed for seamless integration with gear couplings, splined shafts, or direct drive systems.

Precision-machined mounting points ensure perfect alignment with the gearbox and motor, reducing vibration and mechanical stress.

6. Multi-Layer Spooling Capability

Engineered for smooth and controlled multi-layer spooling, which is essential for cranes requiring high lifting heights without an excessively large drum diameter.

注記: The following table provides a general specification range. Custom drums are our specialty.

| パラメーター | 仕様 | メモ |

|---|---|---|

| Drum Core Diameter | 200 MM - 2,000 mm | Custom diameters available based on rope size and application. |

| Drum Length | 500 MM - 6,000 mm | Determined by rope length, number of falls, and layers. |

| Rope Diameter Range | 8 MM - 60 mm | Grooves are machined to match the specified rope diameter. |

| フランジ高さ | 標準: 1.5 x Rope Diameter Multi-layer: As per design |

Ensures safe containment of the rope. |

| Max Rope Capacity | まで 1,000+ メーター | Varies with drum dimensions and spooling layers. |

| 作業負荷制限 (wll) | 1 Ton – 500+ トン | Designed with a safety factor exceeding industry standards (例えば。, fem, から). |

| Mounting Type | Single or Double Flange | Gear Coupling, Splined Shaft, or Direct Drive. |

| 材質グレード | Q235B, Q345B, アイシ 4140, or equivalent high-tensile steel. | |

| 表面処理 | 爆破したショット, 塗装 (標準), 亜鉛メッキ (オプション) |

Our wire rope drums are versatile and can be customized for a wide array of crane applications, 含むがこれに限定されない:

Q1: How do I select the right wire rope drum for my crane?

a: Selection depends on several factors: the crane’s maximum lifting capacity, the wire rope diameter, the required rope length (ドラム容量), the number of spooling layers, and the operating duty cycle. It is highly recommended to consult our engineering team with your crane’s specifications.

Q2: Can you manufacture a replacement drum for my old or obsolete crane model?

a: 絶対に. We specialize in reverse-engineering and manufacturing custom replacement parts. Provide us with the original drawings, or we can take precise measurements from your existing drum to create a perfect, high-performance replacement.

Q3: How often should the wire rope drum be inspected?

a: Visual inspections should be conducted before each shift. A formal, detailed inspection should be performed monthly or as per your crane’s maintenance schedule and in compliance with local safety regulations (例えば。, オシャ, ローラー). Key things to check are groove wear, ひび割れ, and flange integrity.

Q4: What are the signs that a wire rope drum needs to be replaced?

a: 一般的な兆候には次のものがあります:

Excessive wear in the rope grooves, creating a sharp edge that damages the rope.

Visible cracks or deformation on the drum barrel or flanges.

The drum is out-of-round or has been subjected to an overload event.

Q5: Do you offer surface hardening for the rope grooves?

a: はい, we offer induction hardening or hard-chrome plating for the rope grooves as an optional feature. This significantly increases wear resistance and is ideal for high-duty-cycle applications.

For further technical specifications, custom quotes, or engineering support, 当社の営業チームにお問い合わせください.

私たちはあなたのフィードバックを大切にします! あなたの特定のニーズに合わせてサービスを調整できるように、以下のフォームに記入してください.

The core structure of the single girder eot crane consists of a bridge supported at both……

もっと発見してください →

The lifting height limiter effectively mitigates the risks of hook over-lifting, which c……

もっと発見してください →

The 2 tons overhead crane is a versatile and reliable lifting equipment designed to mee……

もっと発見してください →

最新のコメント