重い持ち上げの世界で, the crane hook is an unsung hero. 決勝です, critical link between your massive crane and the invaluable load it carries. While operators meticulously inspect cables for fraying and ensure brakes are functional, one crucial aspect often doesn’t get the attention it deserves: the crane hook dee diameter measurement.

This isn’t just a minor technical detail; it’s a fundamental pillar of lifting safety. Ignoring it can lead to catastrophic equipment failure, コストのかかるダウンタイム, そして, 最も重要なこと, 重傷.

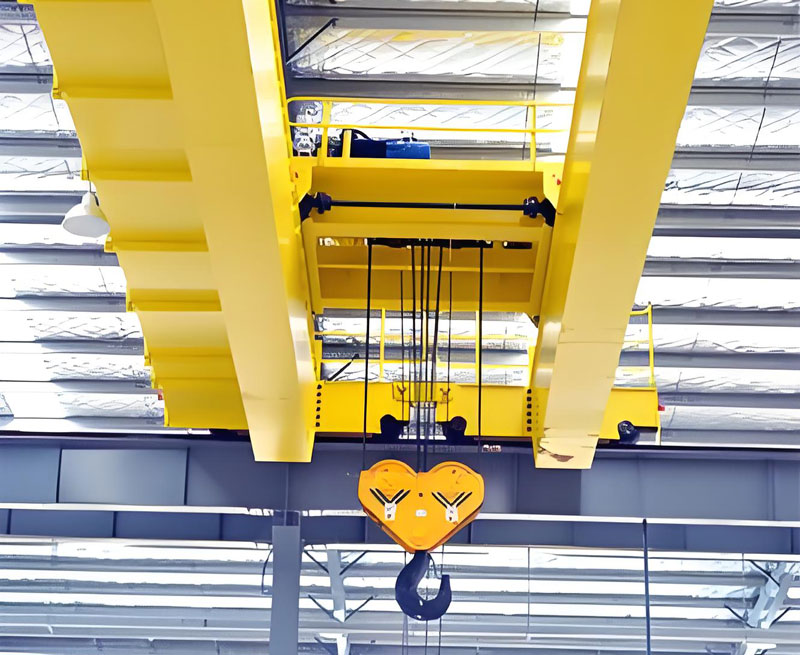

The “Dee” (or “D”) is the curved, semi-circular section of the hook that bears the direct load. It’s designed to allow the wire rope or chain to sit snugly within it, distributing the weight evenly.

時間とともに, this area is subjected to immense stress, 着る, と疲労. As a hook is used, the Dee section can gradually wear down, deform, or even develop cracks. This reduces the original cross-sectional area of the hook, drastically compromising its strength.

Think of it this way: a thicker metal bar can hold more weight than a thinner one. The same principle applies to your crane hook. As the Dee diameter decreases, the hook’s rated capacity plummets. Using a worn hook at its original rated capacity is like trusting a frayed rope to hold a full load—it’s an accident waiting to happen.

Measuring the Dee diameter isn’t a casual glance; it requires precision and the right tools. Here’s the correct process:

Not every millimeter of wear means the hook must be discarded. Industry standards, such as those from ASME B30.10 (フック) とOSHA, provide clear guidelines. 一般的に, a hook must be removed from service if the wear (reduction in diameter) exceeds:

Any signs of twisting, 曲げ, ひび割れ, or throat opening deformation are immediate causes for rejection, regardless of diameter measurement.

The crane hook dee diameter is a small metric with enormous implications. By making its measurement a non-negotiable part of your lifting equipment maintenance program, you are not just protecting your assets—you are actively safeguarding your team and your worksite.

Don’t let the smallest link be your greatest point of failure. 測定, record, and inspect. It’s a simple practice that lifts the standard of safety for everyone.

私たちはあなたのフィードバックを大切にします! あなたの特定のニーズに合わせてサービスを調整できるように、以下のフォームに記入してください.

最新のコメント