クレーンフックは、建設全体で操作を持ち上げる上で重要なコンポーネントです, 製造, 配送, その他の重工業. 安全性とパフォーマンスを確保するため, これらのコンポーネントは、認識されている業界標準に準拠する必要があります. 最も重要な基準の1つは、ASME B30.10です, アメリカ機械技術者協会によって開発されました (asme). このブログ投稿で, ASME B30.10クレーンフックの標準について説明します, その範囲, 要件, クレーン操作における重要性.

ASME B30.10は、ASME B30シリーズのセクションであり、ロード処理アクティビティで使用されるフックに特に対応しています. これには、ホイストで使用されるフックが含まれます, クレーン, とスリング. この標準は、設計のガイドラインを提供します, 検査, テスト, メンテナンス, 運用上の安全性を確保し、失敗のリスクを減らすためのクレーンフックを安全に使用する.

ASME B30.10標準カバー:

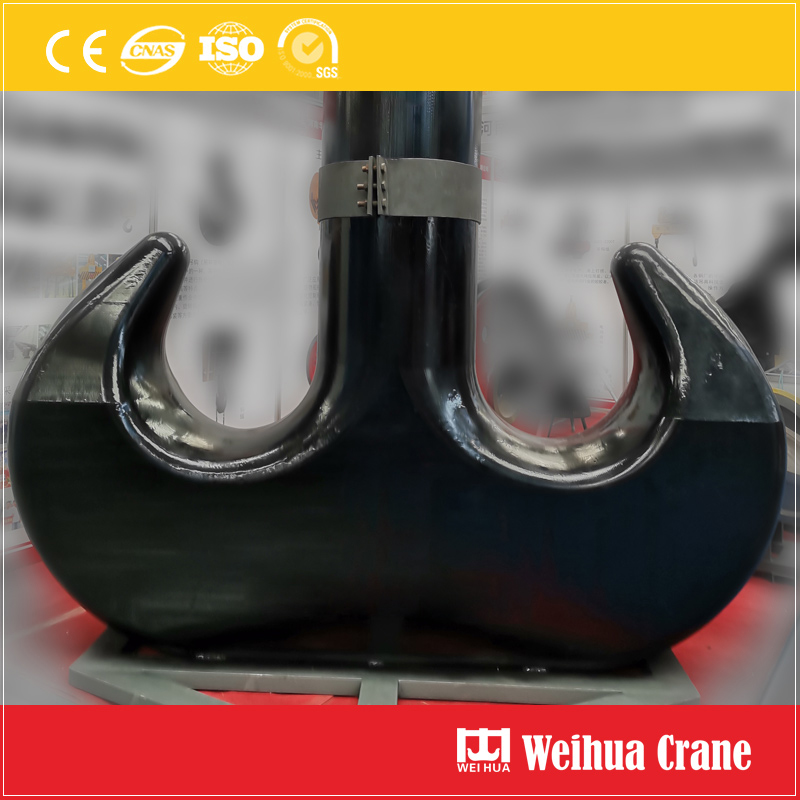

クレーンフックタイプ: アイフックを含む, スイベルクレーンフック, クレビスフック

フック検査基準: 定期的な視覚的および詳細な検査

摩耗と変形の制限

負荷テストと容量の確認

修理および交換プロトコル

オーバーヘッドとガントリークレーンで使用されるフックに適用されます, モバイルクレーン, デリック, ホイスト, とスリング, 特定の特殊なリフティングデバイスを除きます.

頻繁な検査: 明らかなダメージのために毎日または各シフトの前に実行されます, ひび割れ, または歪み.

定期的な検査: 摩耗を検出するために、毎月から毎年の範囲に及ぶ使用頻度に基づいて実施されます, 腐食, または変形.

ASME B30.10によると, 場合、クレーンフックをサービスから削除する必要があります:

のどの開口部はさらに増加します 15%

摩耗は超えています 10% 元の横断面積の

ひび割れ, ニックス, またはガウジが検出されます

曲げ, ねじれ, または、過度の腐食が表示されます

すべてのフックには、はっきりと見える定格負荷容量が必要です, および変更 (例えば。, 溶接, 機械加工) 資格のある人によって承認され、それに応じて再評価する必要があります.

修理は、資格のあるメーカーまたはエンジニアによって実施された場合にのみ許可されます.

熱処理, 溶接, または、再形成は安全プロトコルに準拠する必要があります.

修理後, フックはロードテストを行う必要があります 125% 評価された能力の.

ASME B30.10クレーンフック標準を順守することで保証されます:

フックの故障のリスクを減らすことにより、労働者の安全

定期的な検査とメンテナンスによる運用上の信頼性

OSHAおよびその他の統治体への規制の遵守

拡張されたサービス装置の寿命

遵守しないと、事故が発生する可能性があります, 機器の損傷, 法的責任, メンテナンスコストの増加.

ASME B30.10クレーンフックの標準は、材料の取り扱いとリフティング操作に関与する人にとって不可欠です. クレーンフックが安全であることを確認するための包括的な一連のガイドラインを提供します, 適切に維持されています, 正しく使用されます. あなたがクレーンオペレーターであるかどうか, メンテナンス技術者, または安全検査官, ASME B30.10の理解と適用は、職場の安全を維持し、費用のかかる事件を避けるために重要です.

私たちはあなたのフィードバックを大切にします! あなたの特定のニーズに合わせてサービスを調整できるように、以下のフォームに記入してください.

最新のコメント