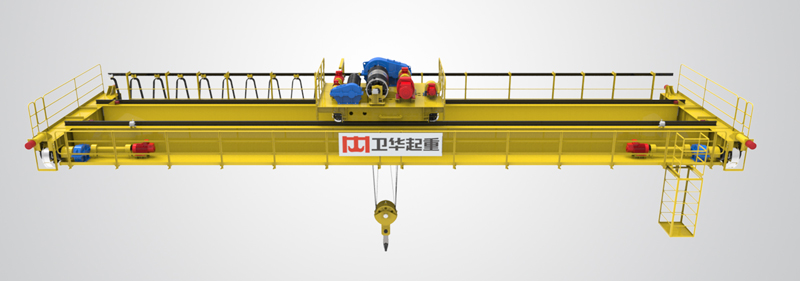

10 Tonnellate a doppia trave sopraelevata (EOT) Crane Product Overview

IL 10 Tonnellate a doppia trave sopraelevata (EOT) Crane is a heavy-duty material handling solution engineered for efficient, sicuro, and reliable lifting operations in various industrial settings. Designed with two parallel girders spanning the working area, this crane delivers exceptional load-bearing capacity and stability, making it an ideal choice for lifting and moving bulky or heavy items up to 10 tonnellate. Whether in manufacturing plants, steel mills, magazzini, o cantieri, this EOT crane enhances productivity by streamlining material flow and reducing manual labor intensity.

10 Tonnellate a doppia trave sopraelevata (EOT) Crane Core Features

- 1. Robust Double Girder Structure: The crane adopts a box-type double girder design, fabricated from high-quality Q235B or Q355B steel plates. This structure ensures excellent torsional rigidity and bending resistance, enabling the crane to withstand heavy loads and frequent operations without deformation. The girders are welded using advanced submerged arc welding technology, with strict non-destructive testing to guarantee welding quality and structural integrity.

- 2. High-Efficiency Hoisting System: Equipped with a heavy-duty hoist unit, the crane features a variable frequency drive (VFD) for smooth lifting and lowering. The hoist motor is a high-torque, squirrel-cage induction motor with class F insulation, ensuring reliable performance even in harsh working conditions. The planetary gearbox provides high transmission efficiency and low noise, while the disc brake offers precise and rapid braking to prevent load slippage.

- 3. Stable Traveling Mechanism: Both the crane traveling (longitudinal movement) and trolley traveling (lateral movement) mechanisms are driven by geared motors with VFD control. The traveling wheels are made of forged steel with high hardness and wear resistance, mounted on precision bearings for smooth rotation. The buffer devices at both ends of the crane and trolley effectively absorb impact energy during start-stop and collision, protecting the crane and surrounding equipment.

- 4. Advanced Control System: The crane is controlled by a pendant station with ergonomic buttons, allowing operators to control all movements precisely. Optional wireless remote control is available for greater flexibility and operator safety, enabling control from a safe distance. The electrical control cabinet is equipped with PLC (Controller logico programmabile) for intelligent control, featuring overload protection, phase failure protection, and emergency stop functions to ensure operational safety.

- 5. Comprehensive Safety Devices: To ensure maximum safety, the crane is equipped with multiple safety protection devices, including overload limiter (prevents overloading), lifting height limiter (stops hoist at upper and lower limits), travel limit switch (limits crane and trolley travel range), pulsante di arresto di emergenza (immediately stops all operations in case of emergency), and anti-collision device (avoids collision between multiple cranes).

Specifiche tecniche

|

Parametro

|

Specifiche

|

|

Capacità di sollevamento nominale

|

10 Tonnellate

|

|

Durata (Distanza tra le rotaie)

|

10m – 30 m (Personalizzabile)

|

|

Altezza di sollevamento

|

6m – 20 m (Personalizzabile)

|

|

Classe operaia

|

A5 – A6 (Medium to Heavy Duty)

|

|

Velocità di sollevamento

|

0.8m/min – 8m/min (Dual Speed Optional)

|

|

Crane Traveling Speed

|

10m/min – 30 m/min

|

|

Velocità di viaggio del carrello

|

5m/min – 20m/min

|

|

Alimentazione elettrica

|

380V/50Hz/3Ph (Personalizzabile per diverse regioni)

|

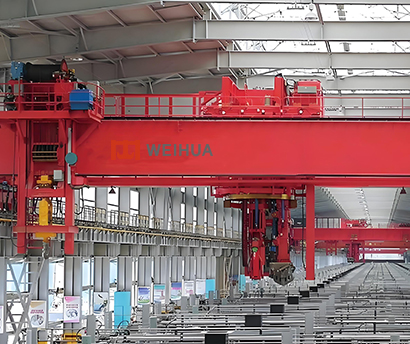

Application Fields

IL 10 Tonnellate a doppia trave sopraelevata (EOT) Crane is widely used in the following industries and scenarios:

- 1. Industria manifatturiera: Used in machinery manufacturing workshops for lifting and assembling large components, such as engine blocks, machine frames, and molds.

- 2. Industria metallurgica: Applied in steel mills and foundries for handling steel ingots, bobine, and castings at high temperatures (with high-temperature resistant options available).

- 3. Magazzinaggio e logistica: Utilized in warehouses and distribution centers for loading, scarico, and stacking heavy goods, improving storage efficiency.

- 4. Industria delle costruzioni: Used in prefabricated construction sites for lifting precast concrete components, steel structures, e materiali da costruzione.

- 5. Power Industry: Applied in power plants for maintaining and installing large equipment, such as generators, trasformatori, and boilers.

Servizio post-vendita

We are committed to providing comprehensive after-sales service to ensure the smooth operation of your crane:

- 1. Professional on-site installation and commissioning by our certified technicians.

- 2. Operator training to ensure safe and proper operation of the crane.

- 3. Regular maintenance and inspection services to extend the crane’s service life.

- 4. Prompt supply of spare parts to minimize downtime.

- 5. 12-month warranty period from the date of commissioning, covering all manufacturing defects.

If you have any custom requirements, such as special span, altezza di sollevamento, or working environment adaptation, please contact us, and our professional team will provide you with a tailored solution.

Condividi con PDF: Scaricamento

Ultimi commenti