The Crosby crane hook is a trusted lifting component designed for high-performance, sicurezza, and durability in industrial lifting applications. Manufactured by The Crosby Group, a globally recognized leader in rigging and lifting hardware, Crosby crane hooks meet or exceed the most rigorous standards, including ASME B30.10 and EN regulations.

High-Strength Forged Alloy Steel

Crosby hooks are drop-forged and heat-treated to provide maximum strength-to-weight ratio and toughness, ensuring durability even under demanding conditions.

Quenched and Tempered Finish

Every hook undergoes a strict quenching and tempering process to enhance fatigue resistance and prolong service life.

Positive Locking Latch System

Most models include a heavy-duty latch system with a positive locking mechanism, reducing the risk of accidental disengagement during lifting.

Wide Range of Sizes and Capacities

Available in a variety of types including eye hooks, ganci girevoli per gru, clevis hooks, and shank hooks, Crosby crane hooks can accommodate working load limits (Wll) da 0.5 tons to over 100 tonnellate.

Full Traceability

Each hook is embossed with a product identification code and batch number, enabling full traceability and compliance with safety standards.

Proof Tested and Certified

All Crosby crane hooks are proof tested to 2 times the working load limit and come with test certification for critical operations.

| Tipo di gancio | Model No. | Limite di carico di lavoro (Wll) | Apertura del gancio (mm) | Dimensioni (L × W × H mm) | Peso (kg) | Materiale | Latch Type |

| Eye Hook | S-320N | 5 Ton Hook alla gru | 51 | 245 × 95 × 45 | 2.3 | Forged Alloy | Heavy-duty Spring Latch |

| Swivel Hook | S-322CN | 10 Ton Hook alla gru | 64 | 310 × 120 × 55 | 6.7 | Forged Alloy | Positive Locking |

| Gancio a forcella | S-330 | 15 tonnellate | 76 | 350 × 130 × 60 | 11.4 | Acciaio legato | Heavy-duty Latch |

| Shank Hook | S-333 | 20 Ton Hook alla gru | 89 | 420 × 150 × 70 | 18.2 | Heat-Treated Steel | Optional Latch |

| Foundry Hook | S-335 | 30 tonnellate | 102 | 485 × 175 × 85 | 28.5 | High-Grade Steel | No Latch (Open Throat) |

| Eye Hook | S-320N | 50 tonnellate | 115 | 550 × 200 × 100 | 42.0 | Forged Alloy | Locking Latch |

| Swivel Hook | S-322CN | 75 tonnellate | 127 | 620 × 230 × 115 | 65.0 | Forged Alloy | Secure Latch System |

| Gancio a forcella | S-330 | 100 tonnellate | 140 | 690 × 260 × 130 | 88.5 | Acciaio legato | Heavy-duty Latch |

Nota: Custom hooks up to 300 tons capacity are available on request.

Crosby crane hooks are engineered for easy integration with a wide range of lifting systems. They can be installed on:

1. Chain slings

2. Wire rope slings

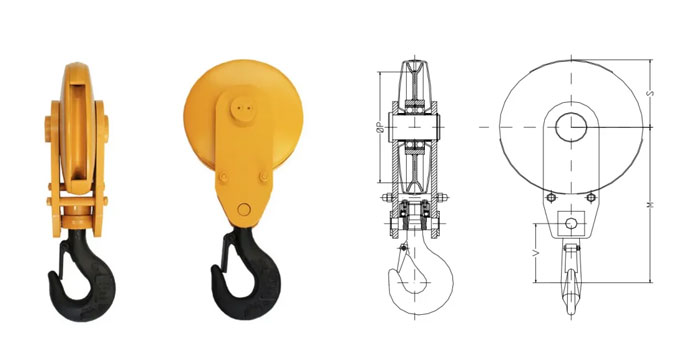

3. Crane blocks

4. Spreader beams

5. Custom lifting assemblies

Detailed installation instructions are provided with each product, and Crosby’s global support team is available to assist with application-specific guidance to ensure proper fit and safety.

To maximize the service life of your Crosby crane hook, regular inspection and maintenance are essential. Key maintenance tips include:

Visual Inspections: Verificare la presenza di crepe, deformazione, corrosione, and excessive wear on the throat and latch.

Function Testing: Ensure latch opens/closes securely and that swivels rotate freely.

Lubrificazione: Apply grease to swivel points and shank connections periodically to prevent seizing.

Test di carico: Conduct proof testing during scheduled maintenance or as part of safety certification renewal.

Crosby offers detailed inspection checklists and documentation to support OSHA and ASME compliance.

All Crosby crane hooks are manufactured in accordance with leading global standards and undergo rigorous testing procedures, compreso:

ASME B30.10 Compliance

IN 1677 Standard

Proof Load Testing Certificates

Magnetic Particle and Ultrasonic Testing (per applicazioni critiche)

Iso 9001 Certified Production Process

These certifications ensure your operations meet regional and international safety regulations.

Crosby crane hooks are available through authorized distributors worldwide. When placing an order, please provide the following:

1. Desired hook type (Eye, Girevole, Forcella, ecc.)

2. Required working load limit (Wll)

3. Application details (lifting angle, intervallo di temperatura, ecc.)

4. Quantity needed

5. Custom specifications (if any)

Industry-leading reliability and performance

Global recognition for safety compliance

Extensive load testing and quality assurance

Wide compatibility with various rigging systems

Whether you’re lifting in the harshest offshore environments or on a construction site, Crosby crane hooks offer the dependable performance professionals rely on worldwide.

Apprezziamo il tuo feedback! Completa il modulo sottostante in modo da poter personalizzare i nostri servizi alle tue esigenze specifiche.

Il nostro gancio per gru a rotazione integra un robusto, meccanici di cuscinetti girevoli con ingegneria con precisione ……

Scopri di più →

Gamma di prodotti core Catene di sollevamento in acciaio in lega Voti: Prodotto a G80 (Grado 8) UN……

Scopri di più →

La nostra soluzione di ganci per gru è dispone di un sistema di gancio pesante progettato per una durata sicura ……

Scopri di più →

Fai clic sul pulsante per ottenere informazioni sul prodotto e citazioni su WhatsApp.

Ottieni una citazione

Ultimi commenti