La nostra marina pesante Gancio della gru is precision-engineered for the rigorous demands of shipyard lifting operations. Costruito per gestire carichi enormi, resistere agli ambienti marini difficili, e garantire la massima sicurezza, this hook is the critical link between your crane and cargo—from engine blocks and steel plates to ship sections and dry-dock equipment.

1. Forza senza compromessi & Durata

Materiale: Forgiato dall'acciaio in lega ad alta resistenza (Grado 100/lega E), trattato termicamente per una robustezza eccezionale.

Capacità di carico: Classificato per SWL (Carichi di lavoro sicuri) da 5 A 500+ tonnellate. Disegni personalizzati disponibili.

Resistenza alla corrosione: Tripla protezione con zincatura a caldo, rivestimento epossidico di grado marino, o varianti in acciaio inossidabile (316L).

2. Sistemi di sicurezza migliorati

Fermo di sicurezza: Caricato a molla, manuale, o i fermi semiautomatici impediscono il disimpegno accidentale.

Protezione da sovraccarico: Celle di carico integrate opzionali per il monitoraggio in tempo reale (Conforme all'API).

Design a prova di errore: Costruzione resistente alla fatica secondo FEM 9.511 e ISO 4301/EN 13889 standard.

3. Ottimizzato per flussi di lavoro marini

360° Rotazione: I ganci girevoli eliminano la torsione della fune metallica durante il posizionamento preciso.

Design a basso profilo: Libera gli spazi ristretti a bordo della nave, mazzi, e strutture di bacino di carenaggio.

Assorbimento degli urti: I cuscinetti reggispinta resilienti riducono lo stress dinamico durante i sollevamenti pesanti.

4. Ispezione intelligente & Manutenzione

Indicatori di usura: Gli indicatori visivi evidenziano le zone critiche di usura (gola, mancia).

Raccordi facili da ingrassare: Le porte di lubrificazione prolungano la durata dei cuscinetti/bulloni.

Tracciabilità: ID inciso al laser con SWL, numero di serie, e dettagli della certificazione.

| Parametro | Specifiche |

| Serie di modelli | MCH-SY (Standard) / MCH PIÙ (Avanzato) |

| Carico di lavoro sicuro (SWL) | 5–500 tonnellate |

| Fattore di sicurezza del progetto | ≥ 5:1 (per ISO 4301) |

| Materiale | Acciaio legato (Grado 100/lega E) |

| Processo di forgiatura | Forgiatura a stampo chiuso, testato ad ultrasuoni |

| Trattamento termico | Spento & temperato (HRC 38-42) |

| Protezione della corrosione | Triplo strato: Fosfatazione allo zinco + HDG + rivestimento epossidico (250µm) |

| Rotazione | 360° rotazione continua |

| Tipo di cuscinetto | Cuscinetto reggispinta a rulli conici (lubrificato con grasso) |

| Fermo di sicurezza | Caricato a molla (standard), semiautomatico, o sensore RFID abilitato |

| Temp. operativa. | -40°C fino a +150°C |

| Vita affaticata | 500,000 cicli @ 60% SWL (Iso 4301-5) |

| Limite di usura | Massimo 10% riduzione della gola / 5% deformazione della punta del gancio (ASME B30.10) |

| Requisiti NDT | MPI ogni 6 mesi; UT per ganci >100 tonnellate |

| Certificazioni | DNV-GL, ABS, Registro dei Lloyd's, CCS, IRS |

| Dimensioni (Esempio) | *MCH-SY 100 tonnellate:* - Gola: 320 mm - Larghezza: 180 mm - Altezza: 785 mm |

Soluzioni su misura per ascensori complessi:

| Requisito | La nostra capacità |

| Ambienti estremi | Ganci di tipo artico (-60° C.), atmosfera esplosiva (ATEX) varianti |

| Carichi non standard | Ganci asimmetrici per sollevamenti angolari, impugnature ergonomiche per componenti delicati |

| Pronto per l'automazione | Pad di interfaccia robotica, sensori ad aggancio automatico, telemetria del carico remoto |

| Kit di aggiornamento | Aggiornamenti delle gru tradizionali con celle di carico digitali + sistemi anticollisione |

| Caratteristica | Valore tecnico | Compatibilità |

| Cella di carico integrata | Precisione ±0,5%., 4-20Uscita mA/RS485 | API9B/ISO 17025 certificato |

| Sistema anti-onde | Smorzamento giroscopico attivo (tempo di risposta: <0.8 sez) | Predisposizione per l'integrazione del PLC della gru |

| Monitoraggio RFID | Tag ISO 18000-6C (memoria: 8 KB) | Sincronizzato con EAM/CMMS |

| Certificazione ATEX | Zona 1/21 (IIB+H2 T85°C) | Chiusure antideflagranti |

| Adattatore a cambio rapido | Interfaccia conforme alla norma DIN 15403 | In palio, Grilli, or magnets |

1. Blocchi a gancio & Assemblies

Ganci tandem: Travi di sollevamento multigancio per il sollevamento equilibrato di carichi irregolari (PER ESEMPIO., moduli della nave).

Pulegge rotanti: I sistemi di pulegge integrati riducono l'abrasione del filo + abilitare la riavvolgimento verticale (Iso 4309 compiacente).

Tecnologia anti-oscillazione: Ganci girostabilizzati con smorzatori inerziali per il posizionamento di precisione in banchine ventose.

2. Allegati intelligenti

Etichettatura RFID: Monitoraggio del carico wireless + registri di ispezione automatizzati (compatibile con piattaforme gru IoT).

Kit di assistenza alla vista: Fotocamere integrate + LiDAR per il monitoraggio degli angoli ciechi durante gli ascensori in spazi confinati.

Adattatori a cambio rapido: Teste del gancio intercambiabili (forcella, preda, grillo) per un rapido cambio di attività.

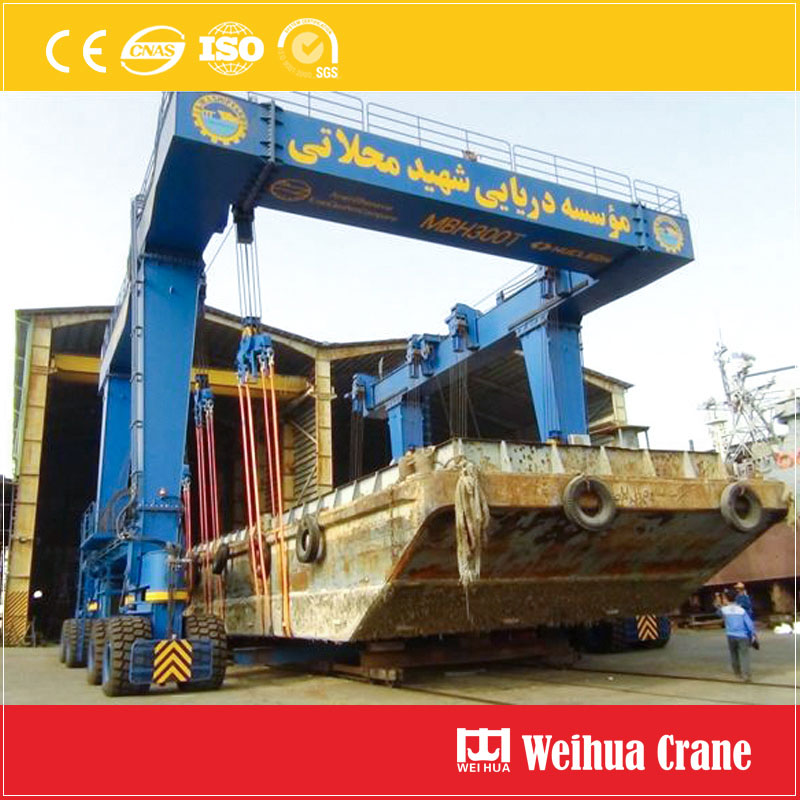

1. Sollevamento in bacino di carenaggio: Sezioni dello scafo, eliche, timoni.

2. Negozi di fabbricazione: Piastre d'acciaio, rastrelliere per tubi, macchinari.

3. Allestimento banchine: Installazioni del motore, cabine modulari.

4. Trasporti pesanti: Operazioni con gru a portale, caricamenti.

Eredità senza guasti: 200,000+ ore di affidabilità operativa nei cantieri navali globali.

Ingegneria personalizzata: Tailored shank lengths, chiavistelli, o tag RFID per la gestione digitale della flotta.

Conformità globale: Certified for EU, NOI, e i regimi asiatici di sicurezza marittima.

Richiedi un Preventivo o un Dossier Tecnico

Migliora la tua sicurezza di sollevamento con ganci costruiti per resistere al sale, tempesta, and strain. Contatta il nostro team di ingegneri per i diagrammi di carico, CAD models, and rapid prototyping.

Apprezziamo il tuo feedback! Completa il modulo sottostante in modo da poter personalizzare i nostri servizi alle tue esigenze specifiche.

Fai clic sul pulsante per ottenere informazioni sul prodotto e citazioni su WhatsApp.

Ottieni una citazione

Ultimi commenti