overhead crane South Africa

South Africa’s industrial sector is a cornerstone of its economy, driven by mining, produzione, logistica portuale, and infrastructure development. At the heart of these operations lies the overhead crane South Africa industry—providing heavy-duty lifting solutions that boost efficiency, enhance safety, and support the country’s most critical industrial processes. From deep underground mines to bustling container terminals, overhead cranes are indispensable tools, tailored to meet South Africa’s unique environmental and operational challenges. In questo blog, we’ll explore the key industrial applications of overhead cranes in South Africa, highlighting how they empower local businesses and align with global industry standards.

As a global leader in crane manufacturing, WEIHUA offers a full range of overhead crane types that are well-suited to South Africa’s diverse industrial needs, complementing the overhead crane South Africa market with reliable, high-performance solutions. These cranes integrate advanced technologies and robust designs, tailored to withstand local environmental challenges and meet strict industry standards. The main types of WEIHUA overhead cranes available for South African businesses include:

A cost-effective and compact solution, WEIHUA single-girder overhead cranes feature a simplified box-girder structure with main welds processed by submerged arc welding and non-destructive testing for durability. With a lifting capacity of 1-20 tonnellate, they are ideal for small to medium-sized workshops, light manufacturing facilities, and small-scale mining auxiliary operations in South Africa, offering easy installation and low maintenance costs.

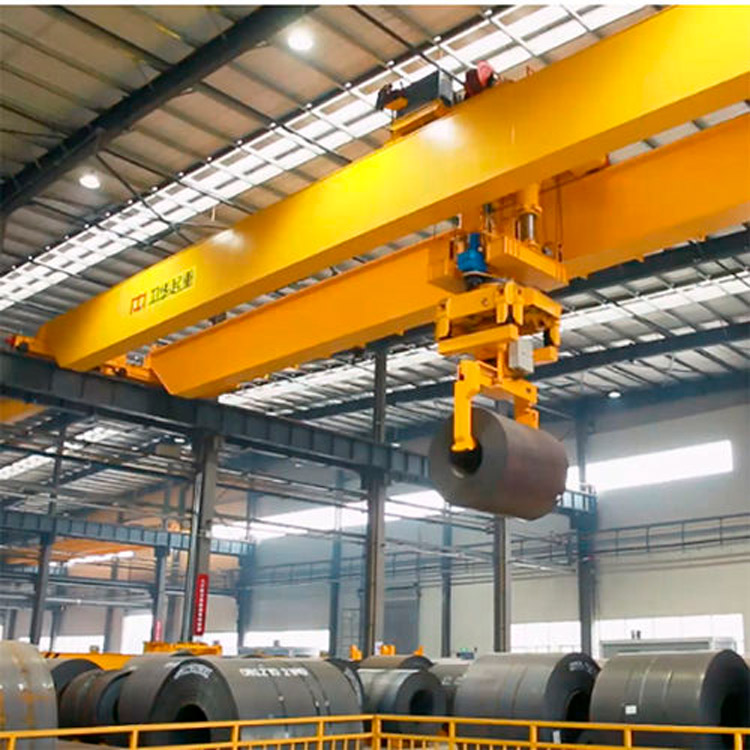

Designed for heavy-duty lifting, WEIHUA double-girder overhead cranes adopt optimized box-girder designs with shot blasting treatment to eliminate stress and prevent rust (reaching Sa2.5 level). Boasting a lifting capacity of 5-500 tonnellate, they are equipped with high-strength bolts for stable connections and advanced anti-sway technology that reduces swing by over 95%. This type is widely used in South Africa’s mining, port, and steel manufacturing industries, handling heavy ore skips, bobine di acciaio, and large equipment.

Tailored for facilities with limited vertical space (such as underground mines and compact workshops in urban South Africa), WEIHUA low-headroom overhead cranes feature a “new Chinese-style” design that reduces overall height by 10%-20% and weight by 15%-30% compared to traditional models. They maintain full lifting capacity while maximizing usable space, making them perfect for South African underground diamond mines and small manufacturing plants with height restrictions.

Engineered for hazardous environments like South Africa’s chemical plants, coal mines, and oil refineries, WEIHUA explosion-proof overhead cranes comply with strict safety standards to prevent sparking. They feature sealed electrical components, rivestimenti resistenti alla corrosione, and flame-retardant materials, paired with intelligent control systems for precise and safe operation. This type effectively mitigates fire and explosion risks in dusty, flammable workplaces, aligning with South Africa’s OHS safety requirements.

Mining is South Africa’s most iconic industry, contributing approximately 7.5% of the country’s GDP and accounting for over 50% of total merchandise exports. This sector relies heavily on overhead crane South Africa solutions to handle the heavy loads, condizioni difficili, and high safety demands of mineral extraction—including gold, platinum, coal, and diamonds.

In gold and platinum mines, gru a ponte (often referred to as bridge cranes) are used to lift and move heavy mining equipment, such as drill rigs, conveyor systems, and ore skips. Grab overhead cranes are particularly vital in tailings treatment systems, where they transport ore and powder in dusty, abrasive environments. These cranes are engineered with high wear resistance, sealed control systems, and dustproof designs to withstand the harsh mining conditions. Inoltre, due to South Africa’s fluctuating power supply, many mining cranes are equipped with variable frequency drives (VFD), remote monitoring, and fault diagnosis systems to ensure continuous operation.

Diamond mines in southern Africa utilize specialized underhung overhead cranes, where I-beams are fixed to the mine ceiling using rock expansion bolts, allowing the crane to glide smoothly below for precise load handling. For underground mines, compact overhead cranes are preferred to navigate limited space while maintaining high lifting capacities—critical for minimizing downtime and maximizing productivity.

South Africa’s strategic location along the Atlantic and Indian Oceans makes its ports—including Durban, Cape Town, and Port Elizabeth—vital hubs for global trade. These ports handle millions of tons of cargo annually, and overhead crane South Africa systems are essential for efficient container and bulk cargo handling.

Durban Container Terminal, one of Africa’s busiest ports, relies on overhead electric cranes (OHECs) for container loading and unloading operations. These cranes must comply with strict industry standards, including ISO regulations and Transnet Code of Practice 29, and undergo third-party load testing (applying 110% of the safe working load) to ensure safety and compliance with South Africa’s Occupational Health and Safety (OHS) Act 85 Di 1993. Liebherr’s LHM 550 mobile harbour cranes are among the equipment used at Durban Port, delivering high productivity for container and bulk cargo operations.

Overhead cranes in ports are designed for high-volume, continuous use, with features like anti-sway technology to minimize cargo damage and precise positioning to speed up turnaround times. They handle everything from containers and vehicles to bulk commodities like coal and iron ore—ensuring South Africa’s exports reach global markets efficiently.

Overhead Cranes In South Africa

South Africa’s manufacturing sector—encompassing automotive, engineering, acciaio, and food processing—relies on overhead crane South Africa solutions to streamline production lines and handle heavy components. From assembling vehicles to fabricating steel structures, overhead cranes are integrated into nearly every stage of manufacturing.

In the automotive industry (home to factories for Ford, Toyota, and other global brands), overhead cranes lift engine blocks, telai del corpo, and large components during assembly. These cranes are often automated to ensure precision and consistency, reducing human error and increasing production speed. For steel manufacturing, overhead cranes handle red-hot steel coils, lingotti, and finished products—requiring heat-resistant designs to withstand extreme temperatures.

Local manufacturers also prioritize customizability, as highlighted by South African crane suppliers who offer tailored solutions to meet specific industry needs. This includes cranes with adjustable lifting speeds, specialized hooks, and automated controls to adapt to the unique requirements of different manufacturing processes.

South Africa’s ongoing infrastructure development—including roads, ponti, centrali elettriche, and commercial buildings—depends on overhead crane South Africa systems to handle heavy construction materials and equipment. As the government pushes for economic recovery through increased infrastructure investment, the demand for reliable lifting solutions continues to grow.

On large construction sites, overhead cranes lift steel beams, pannelli di cemento, and heavy machinery (such as excavators and generators) to great heights. They are particularly useful in urban areas, where space is limited, as they operate above the work area without disrupting ground-level activities. For power plant construction (both thermal and renewable), overhead cranes are used to install boilers, turbine, and other large components—requiring high precision and compliance with strict safety standards.

When choosing an overhead crane South Africa solution, businesses must prioritize factors that align with local conditions and regulations:

Overhead Cranes In South Africa

As South Africa’s industrial sector evolves, theoverhead crane South Africa industry is adapting to meet new demands. Automation and digitalization are becoming increasingly common—with remote monitoring, IoT sensors, and AI-powered maintenance predicting potential issues before they cause downtime. Inoltre, the shift toward renewable energy (such as wind and solar power) is creating new opportunities for overhead cranes in the installation and maintenance of renewable energy infrastructure.

Local suppliers are also investing in sustainable practices, such as energy-efficient crane designs and recyclable materials, to align with global environmental goals. With ongoing infrastructure investment and a focus on industrial modernization, overhead cranes will remain a critical tool for South Africa’s economic growth.

Choosing the right overhead crane South Africa requires a strategic approach that balances your operational needs, local regulations, and long-term usability—ensuring the equipment delivers value while complying with safety standards. Start by assessing your specific lifting requirements: define the maximum load capacity, lunghezza della campata (distance between crane rails), and lifting height needed for your facility, whether it’s a mine, factory, port, or construction site. Per esempio, mining operations may require high-capacity grab cranes with dustproof features, while manufacturing facilities might prioritize compact, automated models.

From mining to ports, manufacturing to construction,overhead crane South Africa solutions are the backbone of the country’s industrial success. These cranes are not just lifting equipment—they are enablers of efficiency, sicurezza, and growth, tailored to meet South Africa’s unique challenges and opportunities. By choosing the right crane supplier, prioritizing compliance and local support, and embracing technological advancements, South African businesses can leverage overhead cranes to stay competitive in a global market.

Whether you’re in the mining industry needing a dust-resistant grab crane, a port requiring a high-capacity container crane, or a manufacturer looking for an automated solution, the overhead crane South Africa industry has the expertise and technology to meet your needs. Contact a trusted local supplier today to find the perfect lifting solution for your operation.

Overhead Cranes In South Africa

To help you make informed decisions about overhead crane South Africa solutions, we’ve compiled answers to the most frequently asked questions from local businesses across mining, produzione, porti, e costruzione.

Q1: What safety standards must overhead cranes in South Africa comply with?

A1: All overhead cranes in South Africa must adhere to the Occupational Health and Safety (OHS) Act 85 Di 1993, SANS 10375:2018 (crane safety and design standards), and SANS 10254 (load testing requirements). Inoltre, cranes used in ports must meet Transnet Code of Practice 29, and operators must hold a valid 4-level certification from the Department of Labour.

Q2: How do I choose the right load capacity for my overhead crane?

A2: Start by calculating the maximum load you’ll need to lift (including any attachments like grabs or hooks), then add a 10-15% safety margin to account for unexpected weight variations. Per esempio, mining operations lifting heavy ore skips may need 50-100 ton capacity, while small manufacturing workshops may only require 5-10 ton cranes.

Q3: Are local overhead crane suppliers in South Africa better than imported options?

A3: Local overhead crane South Africa suppliers (such as BBBEE-compliant, ISO 9001-accredited RGM Cranes) offer key advantages: manutenzione in loco, fast access to spare parts, 24/7 supporto tecnico, and customization tailored to South Africa’s climate and industry needs. Imported cranes may face long lead times for repairs and lack local compliance expertise.Q4: How often do overhead cranes in South Africa need maintenance?

A4: Routine maintenance should be performed monthly (visual inspections, lubrificazione), with comprehensive inspections every 6 mesi. Annual load testing (applying 110% of the safe working load) is mandatory to comply with SANS standards. Mining and port cranes, which operate in harsher conditions, may require more frequent maintenance.

Q5: Can overhead cranes be customized for South Africa’s unique environmental conditions?

A5: Yes—local suppliers specialize in customizing cranes for South Africa’s diverse climate: corrosion-resistant coatings for coastal areas, dustproof and sealed controls for mining regions, and heat-resistant materials for steel manufacturing facilities. They can also integrate VFD systems to handle South Africa’s fluctuating power supply.

Apprezziamo il tuo feedback! Completa il modulo sottostante in modo da poter personalizzare i nostri servizi alle tue esigenze specifiche.

Fai clic sul pulsante per ottenere informazioni sul prodotto e citazioni su WhatsApp.

Ottieni una citazione

Ultimi commenti