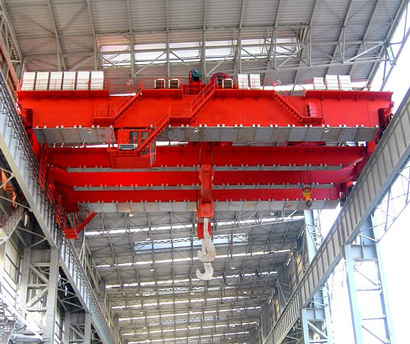

Our Overhead Crane for Foundry is a heavy-duty solution with high-temp resistance (up to 600°C), 5-200t load capacity, dust/corrosion protection & safety compliance. Boost foundry productivity safely.

Permintaan operasi pengecoran kasar, reliable lifting equipment that can withstand extreme conditions—high temperatures, beban berat, abrasive dust, and corrosive materials. Our overhead crane for foundry is engineered specifically to meet these challenges, delivering safe, efisien, and consistent performance for casting processes, from raw material handling to finished product transport. As a specialized heavy-duty lifting solution, it integrates advanced technology and durable components to optimize productivity while minimizing downtime in foundry environments.

|

Parameter

|

Kisaran Spesifikasi

|

|

Kapasitas muatan

|

5t – 200t

|

|

Panjang rentang

|

10m – 35m

|

|

Tinggi pengangkat

|

8m – 30m

|

|

Suhu kerja

|

-20°C – 600°C

|

|

Kecepatan pengangkat

|

0.5m/menit – 10m/menit (dapat disesuaikan melalui VFD)

|

|

Kecepatan Perjalanan

|

10m/min – 40m/min

|

|

Mode kontrol

|

Kontrol liontin, kendali jarak jauh, or cabin control

|

|

Catu daya

|

380V/400V, 3-phase, 50/60Hz (dapat disesuaikan)

|

|

Kelas Perlindungan

|

IP54 – IP65 (komponen listrik)

|

1. Adaptability to Foundry-Specific Challenges

Foundries face unique harsh conditions, and our overhead crane is designed to thrive in them. The heat-resistant structure prevents component deformation under high temperatures, while dust-proof design avoids mechanical jamming from foundry sand and metal particles. It handles corrosive substances like molten slag and chemical additives without performance degradation.

2. Produktivitas yang ditingkatkan & Efisiensi

The crane’s high load capacity and fast, precise operation streamline critical foundry processes. It accelerates raw material (scrap metal, alloys) feeding into furnaces, enables smooth molten metal transfer to molds, and simplifies finished casting handling. Reduced lifting cycle times and minimal downtime boost overall production throughput.

3. Improved Safety for Personnel & Peralatan

Safety is paramount in foundries, and our derek di atas kepala integrates multiple protective features. Overload protection prevents structural damage, anti-sway technology avoids molten metal spills, and emergency stop functions ensure immediate shutdown in emergencies. This reduces accident risks and protects workers, peralatan, and valuable castings.

4. Hemat Biaya & Pemeliharaan rendah

Durable materials and sealed components minimize wear and tear, reducing maintenance frequency and costs. The energy-efficient VFD system lowers power consumption, while the crane’s long service life delivers a high return on investment. Customizable configurations also allow alignment with specific foundry layouts and production needs, avoiding unnecessary expenses.

Q1: Can the overhead crane for foundry handle molten metal directly?

A1: Ya, it is designed with heat-resistant materials and thermal insulation, enabling safe direct handling of molten metal (MISALNYA., baja, aluminium) in temperatures up to 600°C.

Q2: How often does the foundry overhead crane require maintenance?

A2: Routine inspection is recommended monthly, with comprehensive maintenance every 6–12 months—adjustable based on usage frequency and harshness of the foundry environment.

Q3: Can the crane be customized to fit my foundry’s specific span or height?

A3: Sangat. We offer fully customizable span lengths (10m–35m), lifting heights (8m–30m), and load capacities (5t–200t) to match your facility’s layout and production needs.

Q4: Does the crane comply with international safety standards for foundries?

A4: Ya, it meets global standards including ISO, Ce, dan OSHA, with built-in safety features to ensure compliance in hazardous foundry operations.

Q5: What control options are available for the foundry overhead crane?

A5: You can choose pendant control (for short-distance operation), kendali jarak jauh (for flexibility), or cabin control (for precise long-term operation), based on your workflow.

Q6: How long does installation take, and will it disrupt my foundry’s production?

A6: Installation typically takes 1–2 weeks, and we offer off-peak scheduling and modular assembly to minimize production downtime.

Bagikan dengan PDF: Unduh

Kami menghargai tanggapan Anda! Harap lengkapi formulir di bawah ini sehingga kami dapat menyesuaikan layanan kami dengan kebutuhan spesifik Anda.

As a critical piece of equipment in the steel production process, ladle cranes for stee……

Temukan lebih banyak →

Ikhtisar Produk Derek perjalanan di atas kepala, juga dikenal sebagai derek di atas kepala atau derek jembatan……

Temukan lebih banyak →

Apa itu Derek Gantry yang Dipasang di Rel? gantry crane yang dipasang di rel untuk tenaga angin Rel m……

Temukan lebih banyak →

Klik tombol untuk mendapatkan informasi produk dan kutipan di whatsapp.

Dapatkan penawaran

Komentar terbaru