70 Derek Overhead Girder Ganda Ton: High-strength, heavy-duty lifting solution with superior load-bearing capacity, precise VFD control & perlindungan keselamatan yang komprehensif. Customizable for steel mills, galangan kapal & pembangkit listrik.

Sebagai peralatan penanganan material tugas berat profesional, itu 70 tons overhead crane is engineered to meet the rigorous demands of large-scale industrial lifting operations. Designed with advanced technology and robust structural design, ini derek di atas kepala delivers exceptional load-bearing capacity, kontrol yang tepat, dan kinerja yang dapat diandalkan, making it an indispensable asset in industries requiring efficient and safe handling of ultra-heavy loads.

|

Parameter

|

Spesifikasi

|

|---|---|

|

Nilai Kapasitas Pengangkatan

|

70 Ton

|

|

Menjangkau

|

10m – 30m (Dapat disesuaikan)

|

|

Tinggi pengangkat

|

12m – 24m (Dapat disesuaikan)

|

|

Kecepatan pengangkat

|

0.5 – 5 m/saya (Variable Frequency Adjustable)

|

|

Kecepatan Perjalanan Troli

|

5 – 20 m/saya

|

|

Kecepatan Perjalanan Derek

|

10 – 30 m/saya

|

|

Catu daya

|

380V/50Hz/3Ph (Customizable for Different Countries)

|

|

Kelas pekerja

|

A5 – A7 (Suitable for Heavy-Duty Continuous Operation)

|

|

Overall Weight

|

Depends on Span & Tinggi pengangkat (Consult for Detailed Quotation)

|

Itu 70 tons overhead crane is widely used in heavy industry fields that require handling of large and heavy workpieces. Typical application scenarios include:

We adhere to strict quality control standards throughout the production process, from raw material selection to final product testing. Kita 70 tons overhead crane has passed ISO 9001 quality management system certification and relevant international safety certifications (such as CE), ensuring compliance with global industry standards.

To provide customers with worry-free use, we offer comprehensive after-sales services, termasuk:

If you are looking for a reliable 70-ton heavy-duty lifting solution, please contact us for a customized quotation and detailed technical proposal. We are committed to providing you with high-quality products and professional services tailored to your specific needs.

Bagikan dengan PDF: Unduh

Kami menghargai tanggapan Anda! Harap lengkapi formulir di bawah ini sehingga kami dapat menyesuaikan layanan kami dengan kebutuhan spesifik Anda.

Apa itu Derek Gantry yang Dipasang di Rel? gantry crane yang dipasang di rel untuk tenaga angin Rel m……

Temukan lebih banyak →

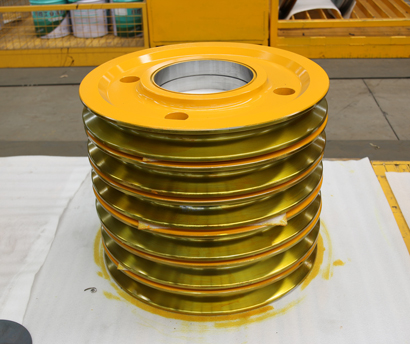

Ikhtisar Produk Katrol tali kawat derek adalah komponen penting dalam mesin pengangkat……

Temukan lebih banyak →

10 Ton Overhead Girder Ganda (EOT) Crane Product Overview The 10 Tons Double Girder ……

Temukan lebih banyak →

Klik tombol untuk mendapatkan informasi produk dan kutipan di whatsapp.

Dapatkan penawaran

Komentar terbaru