Itu 30 tons overhead crane is a core material handling equipment designed for medium-to-heavy industrial applications.

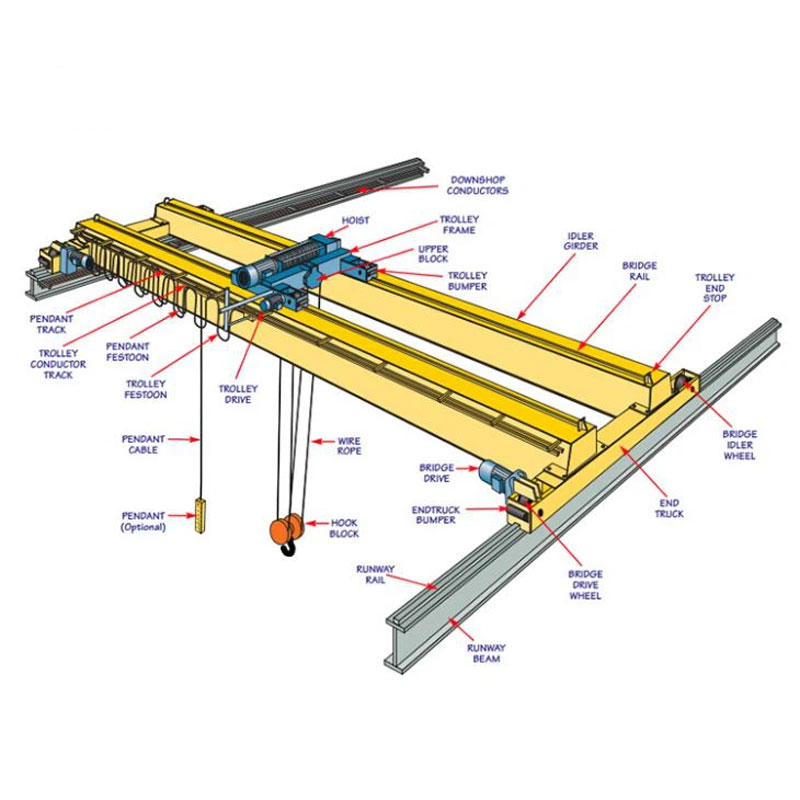

Itu 30 tons overhead crane is a core material handling equipment designed for medium-to-heavy industrial applications. It excels in lifting, bergerak, and positioning loads up to 30 tons with high precision, stabilitas, dan keamanan, making it an indispensable asset for industries requiring efficient heavy-load transportation. Whether in manufacturing workshops, pembangkit listrik, or logistics yards, this crane optimizes workflow, reduces manual labor intensity, and ensures consistent operational efficiency.

Itu 30 tons overhead crane integrates advanced engineering, safety design, and user-friendly functionality, with the following key advantages:

|

Parameter Category

|

Specification Details

|

|

Nilai Kapasitas Pengangkatan

|

30 ton (main hook); 5-10 ton (auxiliary hook, opsional)

|

|

Rentang Rentang

|

10 m – 31.5 M (customizable for special workshops)

|

|

Tinggi pengangkat

|

6 m – 30 M (customizable based on workshop height)

|

|

Kecepatan pengangkat (Main Hook)

|

0.8 – 8 m/saya (variable frequency, stepless regulation)

|

|

Kecepatan pengangkat (Aux Hook)

|

2 – 16 m/saya (jika dilengkapi)

|

|

Longitudinal Travel Speed (Derek)

|

20 – 40 m/saya (variable frequency)

|

|

Transverse Travel Speed (Troli)

|

10 – 20 m/saya (variable frequency)

|

|

Kelas pekerja

|

A5 – A7 (A5: medium-duty, 1,000 working hours/year; A7: heavy-duty, 4,000 working hours/year)

|

|

Catu daya

|

380V/50Hz/3Ph (customizable for 415V/60Hz for international markets)

|

|

Overall Weight

|

15 – 35 ton (varies by span and lifting height)

|

|

Motor Power (Hoisting)

|

18.5 – 37 KW (main hook); 5.5 – 11 KW (auxiliary hook, opsional)

|

|

Motor Power (Longitudinal Travel)

|

2×7.5 – 2×15 kW (one motor per end beam)

|

|

Motor Power (Transverse Travel)

|

1×3 – 1×7.5 kW

|

Itu 30 tons overhead crane is widely used in industries that require heavy-load handling, thanks to its adaptability to different working environments:

While both models handle 30 ton, their structural designs and application scenarios differ significantly. The following table compares key aspects:

|

Dimensi Perbandingan

|

Single-Girder 30 Ton Derek Di Atas Kepala

|

Double-Girder 30 Ton Derek Di Atas Kepala

|

|

Structural Design

|

Single main beam (I-beam or box beam) supported by end beams.

|

Two parallel main beams (box beams) connected by crossbeams.

|

|

Span Adaptability

|

Maximum span ≤ 22 M (limited by single-beam load-bearing capacity).

|

Maximum span ≥ 31.5 M (suitable for large workshops/yards).

|

|

Tinggi pengangkat

|

Umumnya 6 – 18 M (limited by trolley installation space).

|

Umumnya 10 – 30 M (more vertical space for trolley movement).

|

|

Space Occupancy

|

Lower headroom (saves workshop height); smaller overall size.

|

Higher headroom (requires taller workshops); larger footprint.

|

|

Operational Stability

|

Moderate stability (prone to slight beam deflection under heavy loads).

|

Stabilitas tinggi (dual beams distribute load evenly, minimal deflection).

|

|

Load Frequency

|

Suitable for medium-frequency operations (≤ 1,500 cycles/year).

|

Suitable for high-frequency operations (≥ 3,000 cycles/year).

|

|

Cost

|

Lower initial cost (30% – 50% cheaper than double-girder).

|

Higher initial cost (but lower long-term maintenance costs for heavy use).

|

|

Optional Configurations

|

Limited (auxiliary hook, remote control only).

|

Versatile (auxiliary hook, ambil ember, magnet, anti-sway system, dll.).

|

|

Ideal Scenarios

|

Small-to-medium workshops, low-frequency heavy-load handling (MISALNYA., small machinery factories).

|

Large workshops, high-frequency heavy-load handling (MISALNYA., pabrik baja, pembangkit listrik).

|

Q1: What factors should I consider when selecting a 30 ton derek di atas kepala?

A1: Faktor kuncinya meliputi:

Q2: Seberapa sering a 30 ton derek di atas kepala memerlukan perawatan?

A2: Maintenance follows a three-level schedule:

Q3: Bisakah 30 tons overhead crane be customized for special needs?

A3: Ya. Common customizations include:

Q4: What safety certifications are mandatory for 30 tons overhead cranes?

A4: Certifications vary by region, but key ones include:

Q5: What is the service life of a 30 ton derek di atas kepala?

A5: Under normal use and proper maintenance, the service life is 10 – 15 bertahun-tahun. Key factors affecting life include:

Itu 30 tons overhead crane combines power, keamanan, and flexibility to meet the diverse needs of heavy-industry material handling. With customizable designs and reliable performance, it is a long-term investment for improving operational efficiency and ensuring workplace safety. For more details on models, quotes, or custom solutions, please contact our technical team.

Kami menghargai tanggapan Anda! Harap lengkapi formulir di bawah ini sehingga kami dapat menyesuaikan layanan kami dengan kebutuhan spesifik Anda.

Ketika sampai pada efisiensi, aman, dan penanganan material yang tahan lama di bengkel, pabrik……

Temukan lebih banyak →

Sistem Pemandu Tali adalah solusi anti goyangan dan panduan canggih yang dirancang untuk……

Temukan lebih banyak →

Pengantar Derek Overhead Girder Ganda Derek overhead girder ganda adalah rob……

Temukan lebih banyak →

Klik tombol untuk mendapatkan informasi produk dan kutipan di whatsapp.

Dapatkan penawaran

Komentar terbaru