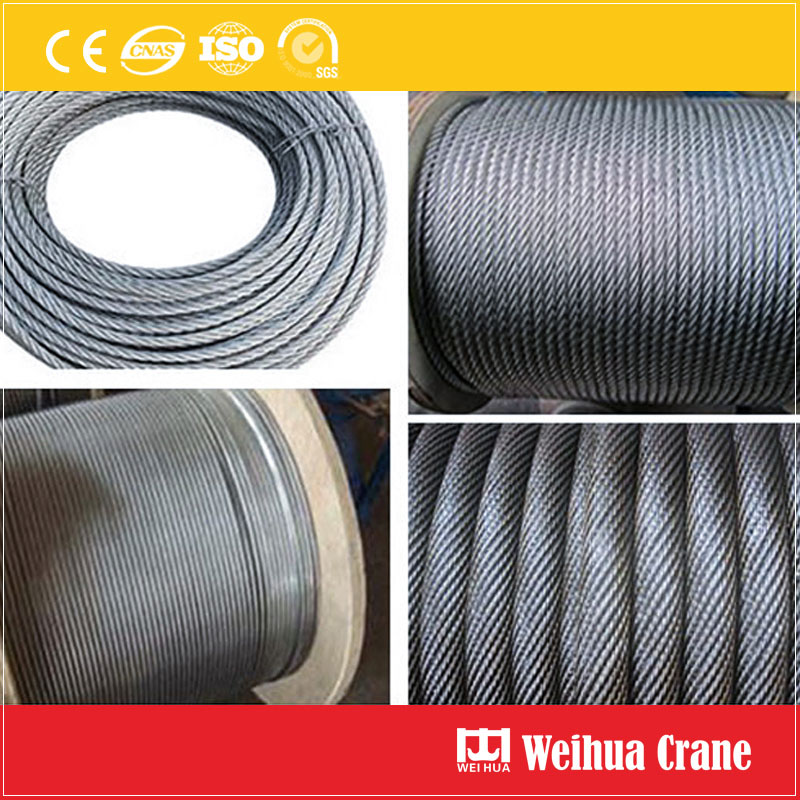

Crane wire rope is a key component used in lifting, lifting and traction equipment. It is made of multiple strands of twisted steel wire and has the characteristics of high strength, wear resistance and corrosion resistance. It is widely used in bridge cranes, crane gantry, container cranes, kerekan listrik, dll..

Dalam dunia penanganan material yang menuntut, konstruksi, dan angkat berat, every component must perform with unwavering reliability. At the heart of these critical operations is the Crane Wire Rope—a product engineered not just to lift, but to endure, to secure, and to empower.

Our crane wire ropes are the culmination of advanced metallurgy, precision manufacturing, and rigorous testing. They are designed to be the strongest, most durable, and safest link in your lifting system, ensuring peak performance in the most challenging environments.

1. Uncompromising Strength & Daya tahan:

Constructed from high-carbon steel with various grades (MISALNYA., IPS, EIP, EEIP), our ropes offer exceptional tensile strength. This means a higher safety factor, greater resistance to breaking, and the ability to handle your maximum workload with confidence.

2. Enhanced Fatigue Resistance:

The constant bending over sheaves and drums is a primary cause of wire rope failure. Our ropes are engineered with optimal core construction and precise strand patterning to withstand millions of bending cycles, secara signifikan memperpanjang masa pakai dan mengurangi downtime.

3. Superior Abrasion Resistance:

We offer a range of surface treatments, including Bright (Uncoated), Galvanis, and Stainless Steel, to combat wear and corrosion. For the toughest conditions, our Wire Rope with Plastic-Impregnated (PVC or Nylon) Coating provides an extra layer of protection against abrasion, kelembaban, and chemical exposure.

4. Exceptional Crush Resistance:

A robust core—whether Independent Wire Rope Core (IWRC) or Fiber Core (FC)—is vital. Our IWRC construction provides superior support against high loads and crushing forces on drums, while our FC offers excellent flexibility and cushioning.

5. Customized for Your Application:

No two lifts are the same. We provide a variety of constructions (MISALNYA., 6×19, 6×36, 6x25FW, 8×19) to match your specific needs:

6×19 Class: A versatile workhorse for general crane service, hoisting, and dragging.

6×36 Class: Offers more wires for greater flexibility, ideal for applications requiring frequent spooling.

Rotation-Resistant: Multi-layer construction designed to prevent spinning under load, essential for single-line, free-hanging lifts.

| Grades | IPS (1770 N/mm²), EIP (1960 N/mm²), EEIP (2160 N/mm²) |

| Cores | Independent Wire Rope Core (IWRC), Fiber Core (FC), Synthetic Core (SC) |

| Constructions | 6x19S, 6x25FW, 6x36WS, 6x41WS, 8x19S, and Rotation-Resistant types. |

| Pelapis | Bright (uncoated), Galvanis (Zinc-Coated), PVC/Nylon Coated, Stainless Steel. |

| Pelumasan | Impregnated with a high-performance lubricant during manufacturing to reduce internal friction and prevent corrosion. |

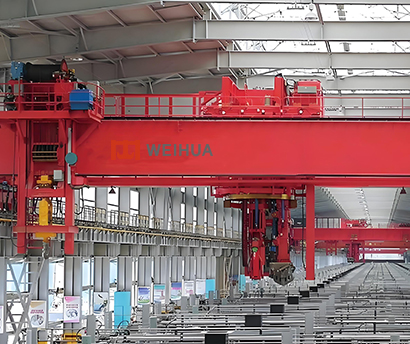

Our crane wire ropes are trusted in a multitude of sectors:

The overarching principle from safety standards like OSHA and ASME B30.2 is: A wire rope must be removed from service when there is evidence of distortion, keausan yang berlebihan, korosi, or damage that could result in a measurable loss of strength or functional integrity.

Dalam praktiknya, this is determined by regular, documented inspections. There are two main categories of inspection:

Choosing the right wire rope is critical. Our technical team is ready to assist you in selecting the perfect rope for your crane’s load capacity, siklus tugas, dan kondisi lingkungan.

Contact us today for a consultation and quote.

Kami menghargai tanggapan Anda! Harap lengkapi formulir di bawah ini sehingga kami dapat menyesuaikan layanan kami dengan kebutuhan spesifik Anda.

Derek Gantri Seluler: WEIHUA Solusi Berkualitas Tinggi untuk Penanganan Material. Gantri Seluler……

Temukan lebih banyak →

Aluminium smelter operations are characterized by harsh working environments, high-temp……

Temukan lebih banyak →

Struktur inti derek girder eot tunggal terdiri dari jembatan yang ditopang di kedua……

Temukan lebih banyak →

Klik tombol untuk mendapatkan informasi produk dan kutipan di whatsapp.

Dapatkan penawaran

Komentar terbaru