Crane hook twisting is more than just a minor annoyance—it’s a significant operational hazard that can lead to safety risks, penundaan proyek, and increased wear on equipment. Whether you’re lifting construction materials, industrial machinery, or shipping containers, a spinning hook can make precision placement difficult and dangerous. This comprehensive guide explores the root causes of crane hook rotation and provides actionable solutions to prevent it, ensuring safer and more efficient lifting operations.

Understanding the cause is the first step toward prevention. The primary reason a crane hook spins is due to the natural untwisting of the wire rope under load. As a load is lifted, the tension in the hoist rope causes it to want to return to its original, manufactured state. This release of built-up torque rotates the hook block. Factors that influence this include:

Implementing the right solution can drastically improve control, keamanan, and efficiency on your job site.

1. Use a Rotation-Resistant (RR) or Torque-Balanced Wire Rope

This is the most fundamental solution. Rotation-resistant ropes are specifically engineered to minimize spinning. They are constructed with multiple layers of strands laid in opposing directions to counterbalance the torque generated under load.

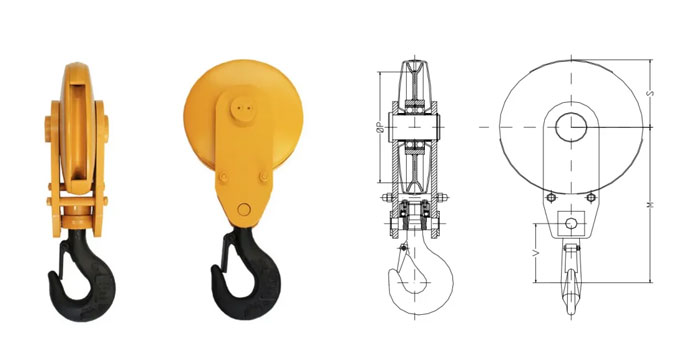

2. Install a Crane Hook Rotator (Rotation Controller or Swivel)

A mechanical rotator or swivel is a device installed between the hook and the lower part of the block. It allows the hook to be manually or remotely rotated intentionally while preventing uncontrolled spinning.

3. Utilize an Anti-Rotation Device or Stabilizer Bar

These are physical attachments that increase the aerodynamic drag and inertia of the hook block, making it harder to start spinning. A simple stabilizer bar is a weighted bar that hangs horizontally, providing a counter-force to any rotational movement.

4. Employ a Tagline (or Tail Line)

This is one of the simplest, most effective, and often overlooked methods. A tagline is a rope attached to the load that an operator on the ground can use to guide and control its orientation and prevent it from spinning.

5. Optimize Crane Operator Technique

Skilled operation is a key defense against hook twisting. Techniques include:

6. Regular Maintenance and Inspection

Often, increased twisting is a symptom of a larger problem. Regular inspection and maintenance are crucial.

The best solution depends on your specific application:

Preventing crane hook twisting is not just about operational convenience; it’s a critical component of jobsite safety. An uncontrolled, spinning load is dangerous for workers, expensive equipment, and the integrity of the load itself.

By understanding the causes and implementing the right mix of solutions—from proper equipment like rotation-resistant ropes and rotators to best practices like using taglines and trained operators—you can achieve smoother, safer, and more productive lifts. Assess your specific needs, consult with crane experts, and invest in the right technology and training to eliminate this common hazard for good.

Kami menghargai tanggapan Anda! Harap lengkapi formulir di bawah ini sehingga kami dapat menyesuaikan layanan kami dengan kebutuhan spesifik Anda.

Klik tombol untuk mendapatkan informasi produk dan kutipan di whatsapp.

Dapatkan penawaran

Komentar terbaru