Derek di atas kepala adalah pekerja keras di pabrik manufaktur, lokasi konstruksi, dan gudang, memainkan peran penting dalam mengangkat dan memindahkan beban berat. Namun, pengoperasiannya yang aman dan efisien sangat bergantung pada inspeksi rutin dan menyeluruh. Mengabaikan inspeksi dapat menyebabkan kegagalan peralatan, kecelakaan kerja, dan waktu henti yang mahal. Di blog ini, kami akan memandu Anda melalui panduan langkah demi langkah tentang cara memeriksa derek di atas kepala dengan benar.

Persiapan Pra-Inspeksi

Sebelum memulai pemeriksaan, persiapan yang tepat sangat penting untuk memastikan prosesnya aman dan efektif.

- 1. Tinjau Dokumentasi: Kumpulkan manual pengoperasian derek, catatan pemeliharaan, dan laporan inspeksi sebelumnya. Ini membantu Anda memahami sejarah derek, masalah apa pun di masa lalu, dan persyaratan pemeriksaan khusus.

- 2. Mempersiapkan Alat dan Perlengkapan: Lengkapi diri Anda dengan peralatan yang diperlukan seperti senter, pita pengukur, Kunci pas torsi, cermin inspeksi, dan kamera untuk mendokumentasikan temuan. Juga, pastikan Anda memiliki alat pelindung diri (APD) seperti topi keras, sepatu keselamatan, sarung tangan, dan tali pengaman jika bekerja di ketinggian.

- 3. Amankan Areanya: Blokir area di sekitar derek untuk mencegah akses tidak sah. Pasang tanda peringatan dan pastikan tidak ada orang yang bekerja atau berjalan di bawah derek selama pemeriksaan.

- 4. Periksa Catu Daya: Pastikan daya derek dimatikan dan dikunci/ditandai (Jantung) untuk menghindari aktivasi yang tidak disengaja selama pemeriksaan.

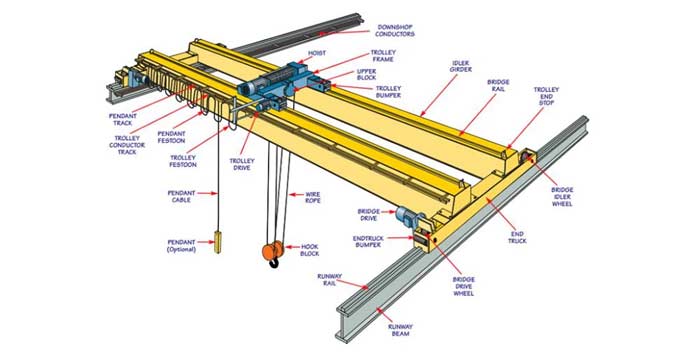

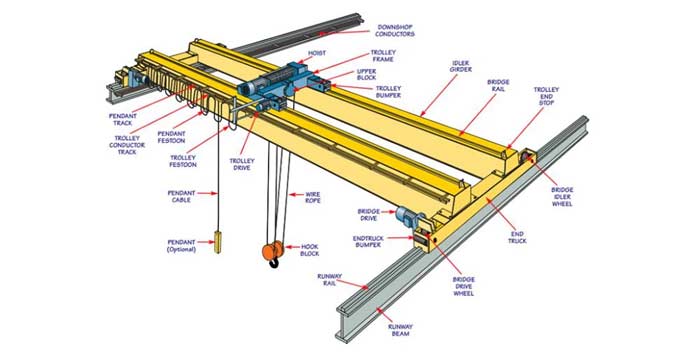

Inspeksi Visual Komponen Utama

Inspeksi visual yang mendetail adalah dasar dari inspeksi derek. Fokus pada komponen penting berikut:

1. Sistem Kerekan

Sistem Kerekan

- Kait Derek Di Atas Kepala: Periksa retakan, deformasi, kenakan di leher pengait atau betis, dan kerusakan pada kaitnya. Pastikan pengait berputar bebas dan kait berfungsi dengan baik untuk mencegah beban tergelincir.

- Tali Kawat: Periksa kabel yang putus, Kinks, korosi, memakai, dan pelumasan yang tidak tepat. Perhatikan area di dekat drum dan berkas gandum yang lebih sering mengalami keausan. Ukur diameter tali untuk memeriksa keausan berlebih—jika di bawah batas yang direkomendasikan pabrikan, ganti talinya.

- Drum dan Berkas: Cari retakan, keausan pada flensa drum atau alur katrol, dan ketidaksejajaran. Pastikan drum tali kawat derek tidak rusak dan tali terpasang dengan benar pada alur tanpa tumpang tindih.

- Sistem Rem: Periksa bantalan rem apakah ada keausan, penyesuaian yang tepat, dan kontaminasi (minyak atau debu). Uji pengoperasian rem untuk memastikan rem dapat menahan beban tetapan dengan aman.

2. Jembatan dan Troli

troli

- Gelagar Jembatan: Periksa gelagar jembatan apakah ada keretakan, pembengkokan, atau distorsi. Periksa sambungan antara girder dan end truck apakah ada kekencangan dan tanda-tanda keausan.

- Troli: Periksa roda troli apakah ada keausan, celah, dan keselarasan yang tepat. Periksa mekanisme penggerak troli, termasuk roda gigi dan bantalan, untuk kebisingan atau kerusakan yang tidak biasa.

- Rel Landasan Pacu: Periksa kelurusan rel landasan pacu, kerataan, dan pakai. Cari pengencang yang longgar, sambungan rel rusak, dan serpihan pada rel yang dapat mengganggu pergerakan crane.

3. Sistem Kelistrikan

kontrol radio derek

- Kabel dan Kawat: Periksa kabel yang berjumbai, koneksi longgar, dan isolasi rusak. Pastikan kabel ditopang dengan benar dan tidak terseret atau bergesekan dengan komponen lain.

- Panel kontrol: Periksa panel kontrol apakah ada tanda-tanda panas berlebih, korosi, atau kerusakan air. Uji tombolnya, saklar, dan indikator untuk memastikannya berfungsi dengan benar.

- Sakelar Batas: Verifikasi pengoperasian sakelar batas atas dan bawah untuk kerekan, serta saklar batas perjalanan untuk jembatan dan troli. Sakelar ini mencegah derek bergerak melampaui batas aman.

Pengujian Operasional

Setelah inspeksi visual, melakukan uji operasional untuk memastikan derek berfungsi dengan baik di bawah beban (jika berlaku) dan kondisi tanpa beban.

- 1. Tes Tanpa Beban: Nyalakan daya dan uji kerekan, menjembatani, dan pergerakan troli ke segala arah. Periksa kelancaran pengoperasian, suara-suara yang tidak biasa, dan pengereman yang tepat. Pastikan sakelar batas aktif ketika derek mencapai batas aman.

- 2. Uji Beban: Lakukan uji beban dengan menggunakan uji beban yaitu 100% ke 125% dari kapasitas terukur derek (ikuti pedoman pabrikan). Angkat beban secara perlahan, memindahkannya secara horizontal, dan turunkan. Amati apakah ada defleksi berlebihan pada gelagar jembatan, suara yang tidak biasa dari komponen, atau masalah dengan sistem rem. Pastikan beban tetap stabil selama pengujian.

- 3. Pemeriksaan Pasca Tes: Setelah menyelesaikan uji operasional, matikan daya dan lakukan pemeriksaan visual terakhir terhadap komponen utama untuk memastikan tidak ada masalah baru yang muncul selama pengujian. Periksa apakah ada pengencang yang longgar atau tanda-tanda stres yang mungkin timbul.

Dokumentasi dan Tindak Lanjut

Dokumentasi yang menyeluruh dan tindak lanjut yang tepat waktu sangat diperlukan untuk menjaga catatan keselamatan crane dan mengatasi masalah dengan segera. Melewatkan langkah ini dapat mengakibatkan masalah yang terabaikan dan berkembang menjadi bahaya besar.

- 1. Catat Detail Inspeksi: Dokumentasikan setiap aspek inspeksi, termasuk tanggalnya, nama inspektur, nomor identifikasi derek, dan daftar lengkap komponen yang diperiksa. Untuk setiap komponen, perhatikan kondisinya—apakah dalam kondisi baik, menunjukkan sedikit keausan, atau memiliki cacat kritis. Lampirkan foto atau video area bermasalah untuk memberikan bukti visual.

- 2. Klasifikasikan Cacat berdasarkan Tingkat Keparahannya: Kategorikan kerusakan untuk memprioritaskan perbaikan: – Kritis: Cacat yang menimbulkan bahaya langsung (MISALNYA., kait retak, tali kawat putus). Derek harus segera dihentikan penggunaannya sampai perbaikan selesai dan diverifikasi. - Besar: Masalah yang bisa menjadi kritis dalam waktu dekat (MISALNYA., bantalan rem yang aus di bawah ketebalan yang disarankan). Jadwalkan perbaikan dalam jangka waktu singkat, dan batasi penggunaan derek jika perlu. – Kecil: Kerusakan kosmetik atau sedikit keausan yang tidak mempengaruhi keselamatan (MISALNYA., sedikit pengelupasan cat). Atasi ini selama pemeliharaan rutin.

- 3. Perbarui Log Pemeliharaan: Integrasikan laporan inspeksi ke dalam log pemeliharaan resmi derek. Log ini harus melacak semua inspeksi, perbaikan, pengganti, dan jadwal pelumasan. Ini berfungsi sebagai catatan sejarah untuk inspeksi di masa depan dan membantu mengidentifikasi masalah yang berulang.

- 4. Komunikasikan dan Tetapkan Tindakan: Bagikan laporan inspeksi dengan pemangku kepentingan terkait, termasuk tim pemeliharaan, pengawas, dan operator derek. Tetapkan tanggung jawab yang jelas untuk memperbaiki kerusakan—tentukan siapa yang akan melakukan pekerjaan tersebut, kapan akan selesai, dan bagaimana hal itu akan diverifikasi. Tindak lanjuti untuk memastikan semua tindakan dilaksanakan sesuai rencana.

Seberapa sering derek di atas kepala perlu diperiksa?

Frekuensi inspeksi overhead crane tergantung pada penggunaan, lingkungan, dan persyaratan peraturan. Berikut adalah pedoman umum:

- 1. Inspeksi Harian: Dilakukan oleh operator sebelum setiap shift. Periksa masalah yang jelas seperti kait yang rusak, kabel longgar, atau suara tidak normal saat startup.

- 2. Inspeksi Bulanan/Triwulanan: Dilakukan oleh personel pemeliharaan. Sertakan pemeriksaan visual yang lebih rinci dan tes operasional dasar.

- 3. Inspeksi Tahunan: Inspeksi komprehensif oleh inspektur yang berkualifikasi (disertifikasi oleh otoritas terkait). Ini termasuk pengujian beban, pengukuran komponen secara rinci, dan diagnostik sistem kelistrikan.

- 4. Setelah Perbaikan Besar atau Kecelakaan: Periksa derek secara menyeluruh setelah perbaikan signifikan, modifikasi, atau insiden (MISALNYA., kelebihan muatan, tabrakan) untuk memastikan aman untuk dioperasikan.

Kesimpulan

Pemeriksaan derek di atas kepala adalah proses sistematis yang menggabungkan persiapan, pemeriksaan visual, pengujian operasional, dokumentasi, dan tindak lanjut. Dengan mengikuti panduan ini, Anda tidak hanya mematuhi peraturan keselamatan tetapi juga melindungi tenaga kerja Anda dari kecelakaan dan memperpanjang masa pakai derek. Ingat, keselamatan tidak boleh dikompromikan—inspeksi rutin merupakan investasi dalam mencegah waktu henti yang mahal dan insiden tragis. Jika Anda tidak yakin tentang aspek apa pun dari pemeriksaan, konsultasikan dengan inspektur derek yang berkualifikasi atau pabrikan untuk mendapatkan panduan.

FAQ Tentang Daftar Periksa Inspeksi Derek Di Atas Kepala

Q1: Bagian penting apa yang biasanya disertakan dalam daftar periksa inspeksi derek di atas kepala?

A: Daftar periksa standar mencakup persiapan pra-inspeksi (tinjauan dokumentasi, persiapan alat/APD, pengamanan kawasan, Jantung), inspeksi visual komponen-komponen utama (sistem kerekan, jembatan/troli, sistem kelistrikan), pengujian operasional (tanpa beban, memuat, pemeriksaan pasca tes), dan dokumentasi/tindak lanjut (mencatat temuan, klasifikasi cacat, pembaruan log pemeliharaan).

Q2: Apa perbedaan frekuensi pemeriksaan untuk harian vs. pemeriksaan tahunan dalam daftar periksa?

A: Pemeriksaan harian (oleh operator) fokus pada masalah yang jelas seperti kait yang rusak, kabel longgar, atau suara startup. Pemeriksaan tahunan (oleh inspektur yang berkualifikasi) bersifat komprehensif, termasuk pengujian beban (100%-125% kapasitas terukur), pengukuran komponen secara rinci, dan diagnostik kelistrikan—keduanya wajib di sebagian besar daftar periksa untuk mencakup keselamatan jangka pendek dan jangka panjang.

Q3: Siapa yang bertanggung jawab untuk melengkapi daftar periksa inspeksi overhead crane?

A: Daftar periksa harian diselesaikan oleh operator derek sebelum setiap giliran kerja. Daftar periksa bulanan/triwulanan ditangani oleh personel pemeliharaan. Daftar periksa tahunan dan pasca perbaikan harus diisi oleh inspektur bersertifikat yang berkualifikasi (sesuai OSHA atau standar peraturan lokal) untuk memastikan kepatuhan.

Q4: Mengapa klasifikasi cacat penting dalam daftar periksa inspeksi?

A: Mengklasifikasikan cacat (kritis, besar, kecil) dalam daftar periksa membantu memprioritaskan tindakan. Cacat kritis (MISALNYA., kait retak) memerlukan penghentian segera; masalah besar (MISALNYA., bantalan rem yang aus) memerlukan perbaikan segera; yang kecil (MISALNYA., pengelupasan cat) pergi ke perawatan rutin. Hal ini mencegah bahaya yang terabaikan dan menyederhanakan alur kerja perbaikan.

Q5: Dapatkah daftar periksa disesuaikan untuk berbagai jenis derek di atas kepala??

A: Ya. Sedangkan bagian inti bersifat universal, daftar periksa harus disesuaikan dengan jenis derek (MISALNYA., derek jembatan, crane gantry) dan skenario penggunaan (tugas berat vs. tugas ringan). Misalnya, daftar periksa port gantry crane dapat menambahkan pemeriksaan tambahan untuk komponen tahan cuaca, sementara derek jembatan gudang mungkin menekankan kesejajaran rel landasan pacu.

Komentar terbaru