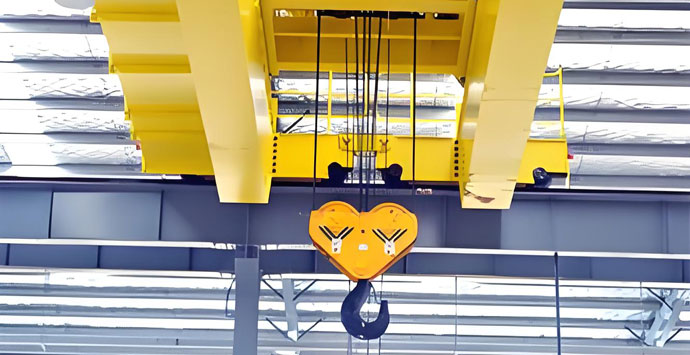

Crane hooks are critical load-bearing components in lifting systems, designed to carry heavy loads safely and efficiently. Namun, like any mechanical part subjected to repeated stress, crane hooks can fail if not properly designed, used, dan dipelihara. A crane hook failure analysis report is essential for identifying the root cause of such failures and preventing future incidents.

Crane hook failures can lead to severe safety hazards, operational downtime, and financial losses. Conducting a thorough failure analysis helps to:

1. Identify the exact cause of the failure

2. Improve future hook design and manufacturing processes

3. Enhance safety protocols for lifting operations

4. Comply with industry safety standards and legal requirements

Based on industry case studies and engineering investigations, the following are the most frequent causes:

1. Material Defects – Inclusions, porosity, or improper heat treatment can weaken the hook.

2. Overloading – Exceeding the Safe Working Load (Swl) leads to plastic deformation or fracture.

3. Fatigue Cracks – Repeated cyclic loading over time can initiate micro-cracks, eventually leading to catastrophic failure.

4. Corrosion – Exposure to harsh environments can reduce material strength.

5. Improper Maintenance – Lack of regular inspection and lubrication accelerates wear and damage.

A professional failure analysis typically involves the following stages:

1. Inspeksi Visual

Initial observation of the broken hook, including fracture surface patterns, deformasi, and wear marks.

2. Dimensional Measurement

Checking the hook’s throat opening, memakai, and dimensional changes against manufacturer specifications.

3. Pengujian material

Chemical Composition Analysis to verify compliance with standards.

Hardness Testing to assess heat treatment quality.

4. Pengujian non-destruktif (Ndt)

Methods like Magnetic Particle Testing (MPT) atau pengujian ultrasonik (Ut) are used to detect internal cracks without damaging the part.

5. Fractography & Microscopic Examination

Scanning Electron Microscopy (SEM) or optical microscopy to study fracture surfaces and identify fatigue striations or brittle fracture features.

6. Load History Review

Checking maintenance logs, operational records, and lifting cycles to determine loading patterns and potential overload incidents.

7. Root Cause Determination

Combining test results, material data, and operational history to conclude whether failure was due to design flaw, manufacturing defect, improper use, or inadequate maintenance.

A detailed crane hook failure analysis report not only identifies the cause but also provides actionable recommendations, seperti:

1. Using higher-grade alloy steels with proper heat treatment.

2. Implementing strict load monitoring systems.

3. Conducting regular NDT inspections.

4. Training operators on correct lifting practices.

5. Applying protective coatings for corrosion resistance.

A crane hook failure is never just a mechanical issue—it is a serious safety concern. By conducting a comprehensive crane hook failure analysis report, industries can prevent future accidents, enhance operational safety, and ensure compliance with lifting equipment standards. The cost of a professional analysis is negligible compared to the potential consequences of another failure.

Kami menghargai tanggapan Anda! Harap lengkapi formulir di bawah ini sehingga kami dapat menyesuaikan layanan kami dengan kebutuhan spesifik Anda.

Klik tombol untuk mendapatkan informasi produk dan kutipan di whatsapp.

Dapatkan penawaran

Komentar terbaru