Di dunia angkat berat, dimana kegagalan bukanlah suatu pilihan, setiap komponen harus direkayasa untuk keandalan mutlak. Inti dari setiap operasi pengangkatan adalah kait derek—peralatan sederhana yang memiliki tanggung jawab besar. Meskipun banyak standar yang ada secara global, satu nama menonjol karena rekayasa yang ketat dan adopsi yang luas, khususnya di Eropa: DARI 15401.

Jika Anda terlibat dalam pengadaan, desain, atau manajemen keselamatan untuk peralatan pengangkat, memahami standar ini sangatlah penting. Mari kita uraikan apa itu DIN 15401 itu dan mengapa itu penting.

DARI 15401 adalah standar industri Jerman yang menentukan dimensi, bahan, pengujian, dan persyaratan penandaan untuk kait derek baja tempa dengan mata betis. Diterbitkan oleh Institut Standardisasi Jerman (Institut Standardisasi Jerman), ini telah menjadi tolok ukur kualitas dan keamanan yang diakui secara global dalam pembuatan kait.

Ini terutama mencakup kait dari tingkat kekuatan M ke atas, yang dirancang untuk aplikasi industri tugas berat. Standar ini memastikan bahwa kait tidak hanya cukup kuat untuk kapasitas terukurnya tetapi juga dirancang untuk menangani tekanan dinamis dan keausan dalam penggunaan di dunia nyata..

Kait Derek Kontainer

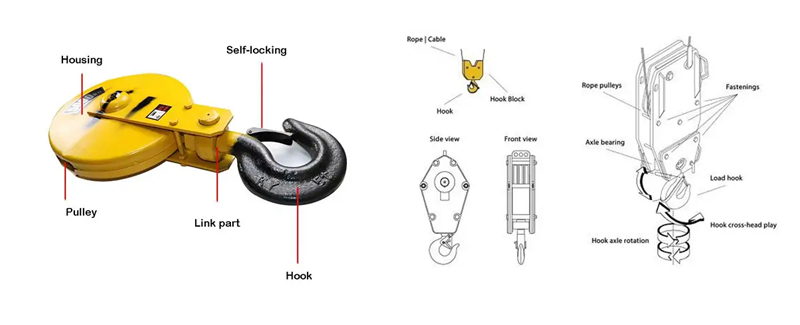

Sebuah pengait yang dibuat untuk DIN 15401 bukan hanya sepotong baja yang melengkung. Ini adalah perangkat keselamatan yang dirancang secara presisi. Berikut adalah ciri-cirinya yang menentukan:

1. Dimensi Standar: Standar ini menyediakan tabel dimensi yang tepat untuk setiap kapasitas beban (MISALNYA., 8T, 16T, 32T). Ini termasuk pembukaan tenggorokan, tinggi kait, diameter betis, dan dimensi mata. Standardisasi ini memastikan pertukaran dan kompatibilitas dengan alat pengangkat lainnya.

2. Mata Betis: DARI 15401 kait memiliki betis yang ditempa dengan mata yang presisi. Mata ini dirancang untuk mengakomodasi clevis atau belenggu, memungkinkan pengait terpasang dengan aman ke mekanisme kerekan derek. Dimensi mata ini sangat penting untuk distribusi beban yang tepat.

3. Kualitas Bahan dan Penempaan: Kait harus terbuat dari bahan berkualitas tinggi, baja paduan berbutir halus (biasanya sebanding dengan 34CrMo4 atau nilai serupa). Proses penempaan menyelaraskan struktur butiran logam dengan bentuk pengait, menghilangkan titik lemah dan menciptakan komponen dengan ketangguhan dan ketahanan lelah yang unggul.

4. Mandat Kait Pengaman: Fitur keamanan inti DIN 15401 adalah ketentuan untuk kait pengaman. Kait pegas ini mencegah sling, rantai, atau beban karena tidak sengaja terlepas dari titik pengait, penyebab utama kecelakaan pengangkatan.

5. Nilai Kekuatan: Standar ini mengklasifikasikan kait ke dalam tingkat kekuatan yang berbeda (seperti M, P, S). Grade M adalah yang paling umum untuk crane tugas berat umum, menunjukkan hasil minimum tertentu dan kekuatan tarik untuk material.

Bagaimana Anda bisa yakin sebuah kail memenuhi DIN 15401? Carilah tanda “Tes”..

Stempel ini, sering ditemukan pada betis kail, tidak diterapkan dengan mudah. Ini menyatakan bahwa hook telah menjalani dan melewati protokol pengujian yang ketat, yang biasanya mencakup:

Pengait dengan tanda “Tes” memberikan ketenangan pikiran karena pengait tersebut diproduksi dengan standar kendali mutu tertinggi.

1. Keamanan Terbukti: Standar ini didasarkan pada pengalaman teknik dan analisis kegagalan selama puluhan tahun. Menggunakan DIN 15401 kait secara drastis mengurangi risiko kegagalan kait.

2. Penerimaan global: Sedangkan standar Jerman, itu dihormati dan digunakan di seluruh dunia, terutama pada crane buatan Eropa dan proyek internasional.

3. Daya Tahan dan Umur Panjang: Bahan berkualitas tinggi dan proses penempaan menghasilkan pengait yang tahan aus, dampak, dan kelelahan, menawarkan masa pakai yang lebih lama.

4. Kepatuhan Hukum dan Asuransi: Penggunaan peralatan bersertifikat sering kali menjadi persyaratan untuk mematuhi peraturan keselamatan kerja (seperti yang diberlakukan oleh OSHA yang setara) dan dapat menjadi krusial jika terjadi klaim asuransi.

Penting untuk dicatat bahwa DIN 15401 sebagian besar telah digantikan oleh standar internasional seperti FEM 9.755 dan iso 7595. Namun, prinsip-prinsipnya, ukuran, dan persyaratan keselamatan sebagian besar diselaraskan. Banyak produsen yang masih menyebut “DIN 15401” karena merupakan sebutan yang terkenal dan tepercaya. Dalam praktiknya, kait yang dibuat untuk FEM 9.755 atau ISO 7595 akan sepenuhnya kompatibel dan kinerjanya setara dengan pendahulunya DIN.

Kait derek yang sederhana adalah mahakarya teknik yang terfokus. DARI 15401 memberikan cetak biru untuk komponen penting ini, memastikan bahwa itu kuat, tahan lama, Dan, terpenting, aman. Saat menentukan atau memeriksa kait derek, mencari keunggulan standar ini—dimensi yang tepat, kait pengaman, dan tanda “Pengujian” yang penting—adalah langkah pertama dalam memastikan operasi pengangkatan yang aman dan efisien.

Kami menghargai tanggapan Anda! Harap lengkapi formulir di bawah ini sehingga kami dapat menyesuaikan layanan kami dengan kebutuhan spesifik Anda.

Klik tombol untuk mendapatkan informasi produk dan kutipan di whatsapp.

Dapatkan penawaran

Komentar terbaru