उत्पाद अवलोकन

The crane wire rope pulley is a critical component in lifting machinery, designed to support and guide wire ropes in crane systems. It plays a vital role in reducing friction between the wire rope and the pulley, minimizing wear on both components, and ensuring smooth, कुशल, and safe load lifting operations. Suitable for various types of cranes, शामिल ओवरहेड क्रेन, गैंट्री क्रेन्स, टावर क्रेन, and mobile cranes, this pulley is engineered to meet the rigorous demands of industrial lifting applications.

Crane Pulley Core Features

- 1. Durable Material Construction: Manufactured from high-strength cast iron, अलॉय स्टील, or ductile iron, the pulley boasts excellent wear resistance, impact toughness, and load-bearing capacity. The material is carefully selected to withstand heavy loads, frequent use, and harsh industrial environments such as high temperatures, नमी, and dust.

- 2. Precision Machined Groove: The pulley groove is precision-machined to match the diameter of the wire rope, ensuring optimal contact between the rope and the pulley. This design reduces rope wear, prevents rope slippage, and distributes the load evenly, enhancing the overall service life of both the pulley and the wire rope.

- 3. High-Quality Bearing System: Equipped with premium rolling bearings (such as deep groove ball bearings or tapered roller bearings) or plain bearings, the pulley operates with low friction and smooth rotation. The bearing system is sealed to prevent the ingress of dust, dirt, and moisture, reducing maintenance requirements and extending the pulley’s operational life.

- 4. Corrosion Resistance Treatment: The surface of the pulley undergoes professional anti-corrosion treatment, including galvanization, painting, or powder coating. This treatment effectively protects the pulley from rust and corrosion, making it suitable for outdoor or corrosive industrial environments.

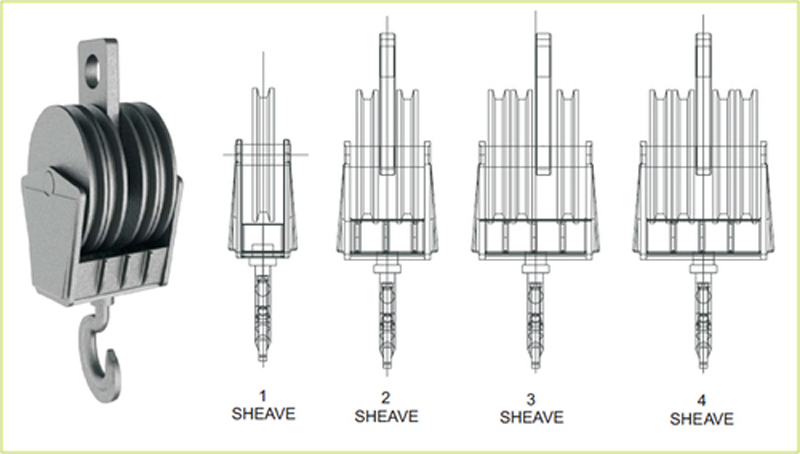

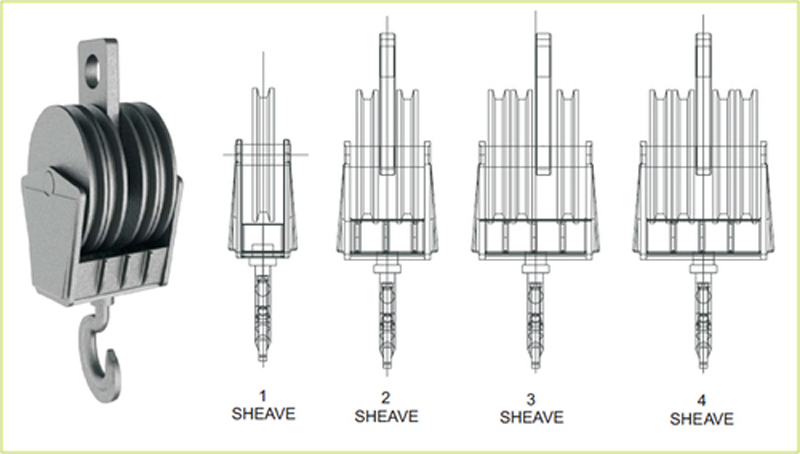

- 5. अनुकूलन योग्य डिज़ाइन: Available in a wide range of sizes, groove types, and mounting configurations to accommodate different wire rope diameters, भार क्षमता, and crane models. We can also provide custom pulleys according to customers’ specific technical requirements and drawing specifications.

Crane Wire Rope Pulley Technical Specifications

|

पैरामीटर

|

विनिर्देश

|

|

Pulley Diameter Range

|

100mm – 1200mm (अनुकूलन)

|

|

रेटेड भार क्षमता

|

0.5t – 500t

|

|

Applicable Wire Rope Diameter

|

6mm – 80mm

|

|

Rotation Speed

|

≤ 300r/min

|

|

सामग्री

|

Cast Iron (HT200/HT250), अलॉय स्टील (45#, 40Cr), Ductile Iron (QT450/QT500)

|

|

सतह का उपचार

|

Hot-Dip Galvanization, Electroplating, Spray Painting, Powder Coating

|

|

बेरिंग के प्रकार

|

Deep Groove Ball Bearing, Tapered Roller Bearing, Plain Bearing

|

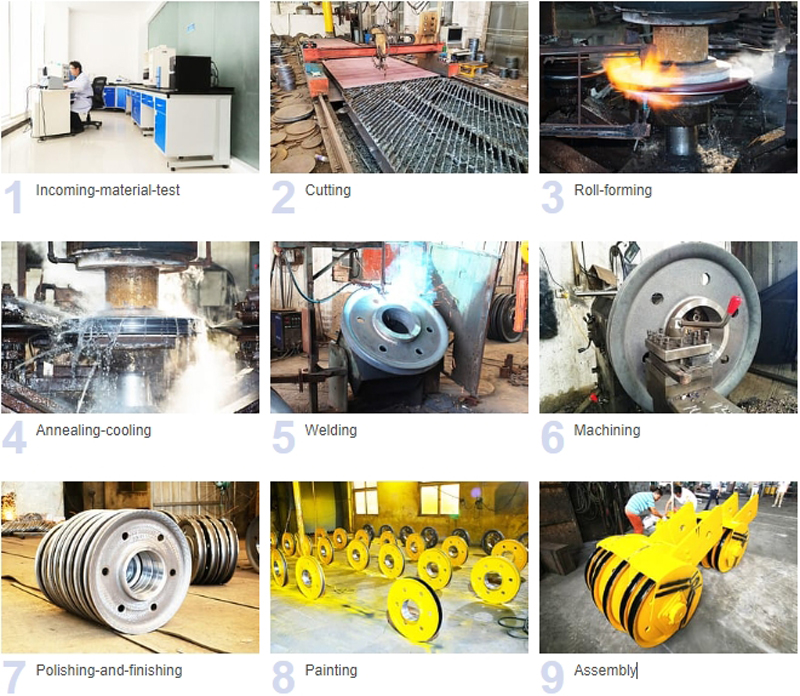

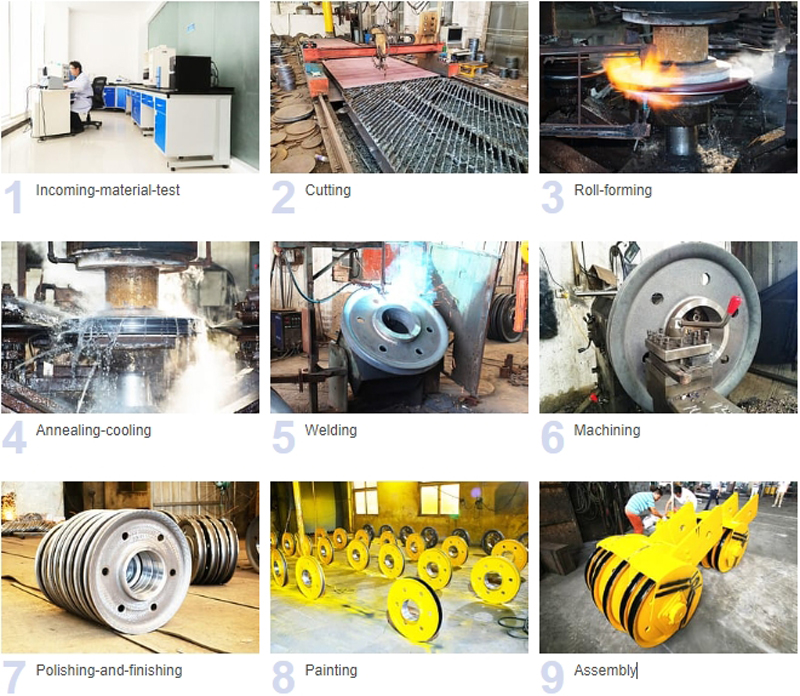

Crane Wire Rope Pulley Manufacturing Process

अनुप्रयोग परिदृश्य

The crane wire rope pulley is widely used in various industrial fields where lifting operations are required, शामिल:

- 1. Manufacturing Industry: Used in factory workshops for lifting heavy machinery, workpieces, and materials in automotive, machinery manufacturing, and aerospace industries.

- 2. Construction Industry: Applied in tower cranes, गैंट्री क्रेन्स, and mobile cranes for lifting construction materials such as steel bars, concrete, and building components on construction sites.

- 3. Port and Logistics: Utilized in port cranes and container cranes for loading and unloading containers, bulk cargo, and other goods.

- 4. Mining Industry: Used in mining cranes for lifting ore, उपकरण, and personnel in mines and mineral processing plants.

- 5. Power Industry: Applied in cranes for installing and maintaining power equipment such as transformers, जेनरेटर, and transmission towers.

Product Advantages

- 1. लंबी सेवा जीवन: High-quality materials and precision manufacturing ensure a longer service life compared to ordinary pulleys, reducing replacement frequency and costs.

- 2. बढ़ाया सुरक्षा: The stable structure, anti-slip groove design, and reliable bearing system minimize the risk of equipment failure and accidents during lifting operations.

- 3. Improved Efficiency: Low-friction rotation reduces energy consumption and ensures smooth load lifting, improving the overall work efficiency of the crane system.

- 4. आसान रखरखाव: Sealed bearing design and corrosion-resistant surface treatment reduce maintenance workload and downtime, saving time and labor costs.

गुणवत्ता आश्वासन

Our crane wire rope pulleys are produced in strict accordance with international standards (such as ISO, से, and GB) and undergo rigorous quality inspection procedures, including material testing, dimensional inspection, dynamic balance testing, and load-bearing testing. We provide a quality guarantee period of 12 months from the date of delivery. In case of any quality problems within the guarantee period, we will provide free replacement or repair services.

हमसे संपर्क करें

If you are interested in our crane wire rope pulley or have any questions about product specifications, prices, or customization, please feel free to contact us. Our professional sales team will provide you with timely and detailed consultation services.

पीडीएफ के साथ साझा करें: डाउनलोड करना

नवीनतम टिप्पणियां