When you think of heavy lifting on a construction site, in a shipyard, or at a manufacturing plant, the image of a crane is almost always front and center. And swinging at the end of that crane’s cable is its most critical point of contact: हुक.

A crane hook is a deceptively simple piece of equipment. It’s a curved piece of metal, right? यथार्थ में, it is a masterpiece of engineering and precision manufacturing, designed to handle immense loads with unwavering reliability. A single flaw in its creation can lead to catastrophic failure.

इसलिए, how is this vital lifting component made? Let’s dive into the fascinating crane hook manufacturing process.

क्रेन हुक निर्माण प्रक्रिया

It all starts long before any metal is touched. Engineers use sophisticated Computer-Aided Design (CAD) software to model the hook. They calculate the precise dimensions, curvature, and throat opening based on the intended Safe Working Load (स्वर्ग). Factors like material grade, stress distribution, and safety factors (अक्सर 4:1 या 5:1) are meticulously programmed into the design. Finite Element Analysis (फी) software is used to simulate loads and identify potential stress points, ensuring the design is optimized for strength and safety.

You can’t make a reliable hook from just any metal. Forging-grade alloy steel is the material of choice for high capacity crane hook. Its exceptional strength, बेरहमी, and resistance to impact make it ideal for heavy lifting. The specific grade (उदा।, ऐसी 4140, ASTM A508) is carefully selected to meet the required mechanical properties. The raw material typically comes in the form of large, cylindrical billets.

This is where the hook gets its strength. The steel billet is heated to a precise temperature in a furnace until it becomes red-hot and malleable (often over 1200°C / 2200° F). This extreme heat allows the steel’s internal grain structure to be reshaped.

The glowing billet is then placed under a massive forging press or hammer. Using immense pressure (thousands of tons), the press forces the metal into a die that has the exact shape of the desired hook. This hot die forging process compresses the internal grain flow of the metal to follow the contour of the hook, dramatically increasing its strength and fatigue resistance compared to a hook that is simply cut from a block of steel.

After forging, the hook is very strong but also brittle. To achieve the perfect balance of strength and durability, it undergoes a rigorous heat treatment process:

The forged and heat-treated hook, now called a “blank,” is rough but incredibly strong. अगला, it moves to the machining department. Computer Numerical Control (CNC) lathes and milling machines are used to:

1. Machine the saddle (the top area) to a smooth finish.

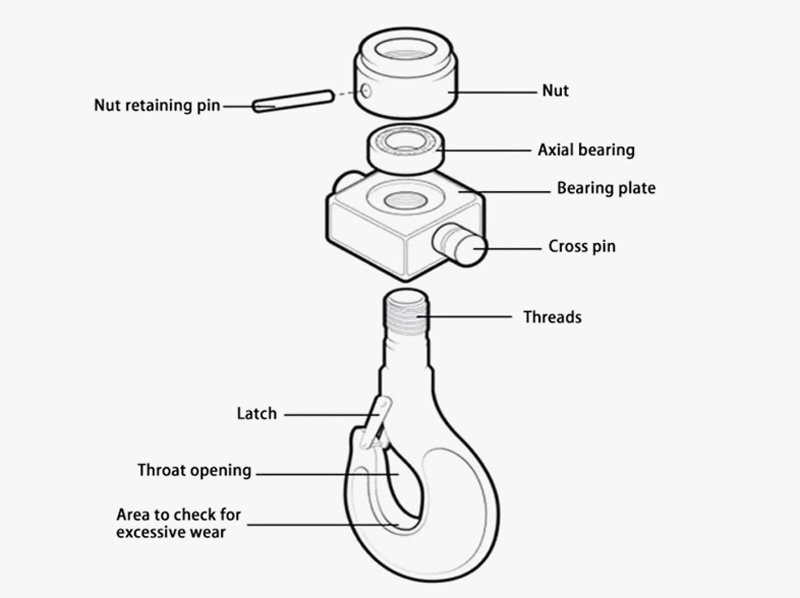

2. Create the precise threads for the nut and collar assembly.

3. Machine the point of the hook and the throat area to the final specified dimensions.

4. Drill the hole for the safety latch.

This stage ensures all critical load-bearing surfaces are smooth and precise, eliminating any potential stress risers like tool marks or imperfections from forging.

This is arguably the most important phase. Every single hook must pass a battery of rigorous tests:

अंत में, the hook is shot blasted to remove scale, rust, and impurities from the surface. This creates a clean, slightly rough profile ideal for paint adhesion. A durable coat of industrial-grade paint (often a high-visibility color like yellow or orange) is applied to protect it from corrosion and make it highly visible on the job site.

The manufacturing process of a क्रेन हुक is a perfect blend of raw power, metallurgical science, and precision engineering. It’s a process built on a culture of safety and quality control. The next time you see a crane effortlessly lifting a massive load, you’ll appreciate the incredible journey that simple-looking hook undertook to ensure it does its job safely and reliably, every single time.

हम आपकी प्रतिक्रिया को महत्व देते हैं! कृपया नीचे दिए गए फ़ॉर्म को पूरा करें ताकि हम आपकी सेवाओं को आपकी विशिष्ट आवश्यकताओं के लिए दर्जी कर सकें.

उत्पाद जानकारी प्राप्त करने के लिए बटन पर क्लिक करें और व्हाट्सएप पर उद्धरण.

उद्धरण प्राप्त करना

नवीनतम टिप्पणियां