Grue à portique sur rail (RMG): High-capacity, customizable lifting solutions for ports, container yards & industrial facilities. Boost efficiency with stability, sécurité & peu d'entretien.

rail mounted gantry crane for wind power

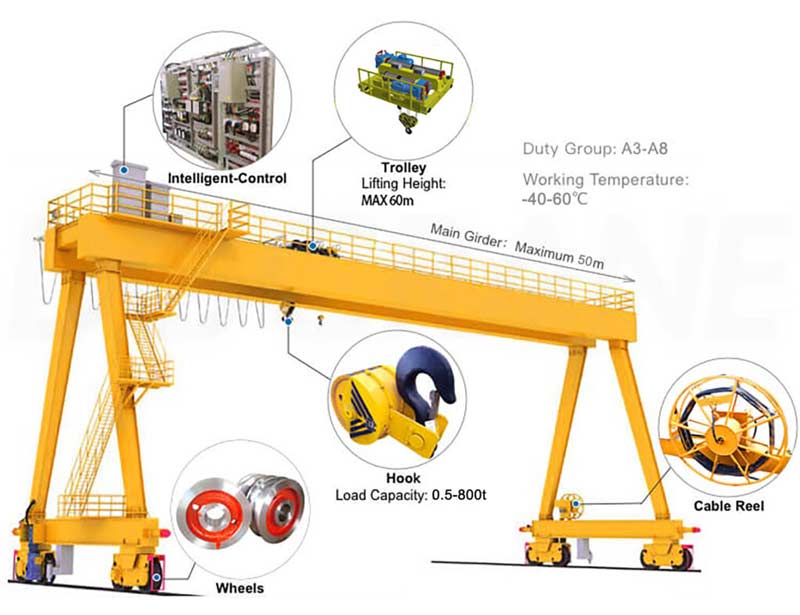

Un portique monté sur rail (Grue RMG) is a robust, high-capacity lifting system designed to operate on fixed rail tracks, making it ideal for precise, repetitive material handling in large-scale facilities. Engineered to handle heavy loads—from containers and bulk goods to industrial equipment—RMG cranes deliver unmatched efficiency in ports, container yards, intermodal terminals, and industrial storage facilities.

Whether you need to streamline container stacking, accelerate cargo turnover, or optimize yard space, our rail mounted gantry cranes are built to meet the demands of high-throughput operations.

rail mounted gantry crane for containers

Our RMG cranes are designed with cutting-edge technology and durable materials to ensure reliability, sécurité, et des performances à long terme. Here’s what sets them apart:

|

Paramètre

|

Gamme (Personnalisable)

|

|

Capacité de levage maximale

|

20T – 150T

|

|

Longueur de portée

|

10m – 40m

|

|

Hauteur de levage

|

6m – 25m

|

|

Vitesse de déplacement

|

0-40 m / mon (réglable)

|

|

Vitesse de levage

|

0-15 m / mon (réglable)

|

|

Alimentation électrique

|

380V/50 Hz (or custom)

|

|

Système de contrôle

|

Remote control + cabin operation

|

Our RMG cranes are versatile enough to serve multiple industries, y compris:

portique sur pneus (RTG) grues

Understanding the differences between Rail Mounted Gantry Cranes (RMG) and Rubber Tyred Gantry Cranes (RTG) is crucial for selecting the right material handling solution. Below is a detailed comparison of their core advantages:

|

Dimension de comparaison

|

Grue à portique sur rail (RMG)

|

|

|

Mobility & Flexibilité

|

Operates on fixed rails for stable, predictable movement; ideal for dedicated work zones with consistent workflows.

|

Tire-based design enables unrestricted movement across yards; suitable for dynamic layouts requiring frequent repositioning. 5G-enabled remote control models enhance operational flexibility further.

|

|

Capacité de chargement & Stabilité

|

Superior stability from rail foundation; supports 20T–150T loads (customizable for ultra-heavy cargo) with precise positioning.

|

Typically handles 40T–60T loads; tire suspension may reduce stability for extreme weights or high stacking heights.

|

|

Space Utilization

|

Dense stacking capability (jusqu'à 6+ containers high) maximizes yard space; rail layout optimizes traffic flow for high-throughput operations.

|

Requires wider turning radii and spacing between units; limits stacking density compared to RMG systems.

|

|

Efficacité énergétique & Entretien

|

Regenerative braking and low-power motors cut energy costs; minimal moving parts in rail systems reduce maintenance frequency.

|

Electric RTG models reduce diesel consumption, but tire replacement and suspension maintenance add long-term costs.

|

|

Application Suitability

|

Best for large-scale container terminals, intermodal yards, and industrial facilities with fixed, high-volume workflows.

|

Preferred for medium-sized yards, temporary projects, or facilities needing periodic layout adjustments.

|

For operations prioritizing stability, heavy-load handling, and space efficiency, RMG cranes deliver long-term value. RTG systems excel in scenarios requiring flexible, on-demand positioning.

Q1: How often does a rail mounted gantry crane require maintenance?

UN: Routine maintenance (lubrification, inspection) is recommended every 3 mois, with major servicing annually—our team can schedule and perform these checks for you.

Q2: Can RMG cranes operate in narrow spaces?

UN: Oui, we offer compact models with reduced span lengths to fit tight yards while maintaining high performance.

Q3: Are your cranes compliant with safety regulations?

UN: Absolument. All our RMG cranes meet OSHA, UE, and international safety standards, with built-in features to prevent accidents.

Ready to boost efficiency in your facility? Contact us today for a free consultation and quote. Our experts will help you select the perfect rail mounted gantry crane for your needs.

Partager avec PDF: Télécharger

Nous apprécions vos commentaires! Veuillez remplir le formulaire ci-dessous afin que nous puissions adapter nos services à vos besoins spécifiques.

The core structure of the single girder eot crane consists of a bridge supported at both……

Découvrir plus →

Steel Coil Handling Overhead Crane For Sale Designed exclusively for the rigorous deman……

Découvrir plus →

Le 200 Le pont roulant de tonnes est un équipement de levage robuste conçu pour répondre aux dema……

Découvrir plus →

Cliquez sur le bouton pour obtenir des informations et des citations de produits sur WhatsApp.

Obtenez un devis

Dernières commentaires