Un voyage aérien électrique (Eot) La grue est un type de grue industrielle conçue pour le levage, abaissement, et déplacer des charges lourdes horizontalement au sein d'une installation.

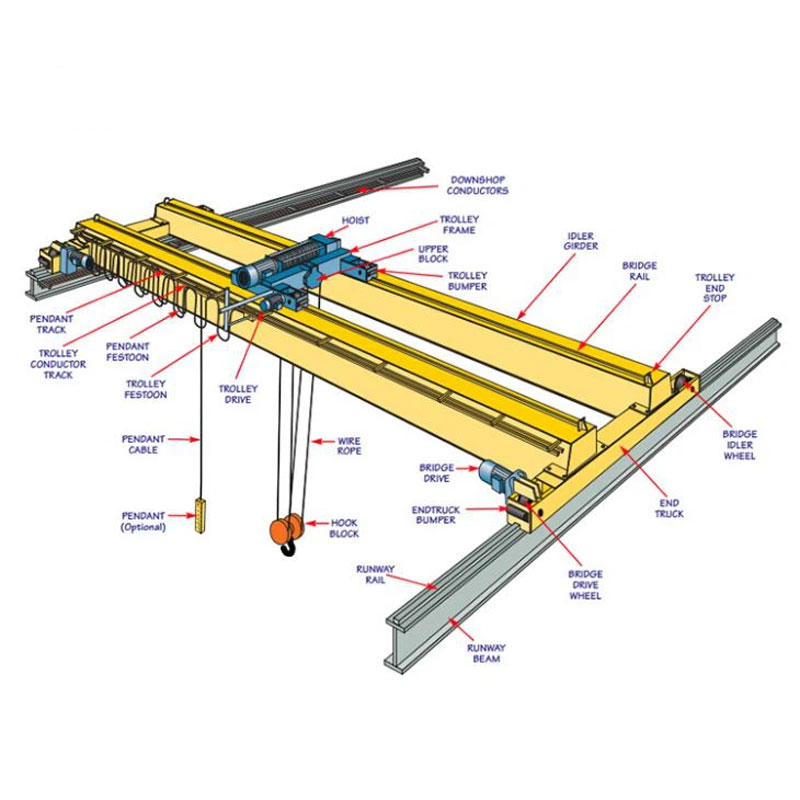

Diagramme de structure de grue EOT

La grue EOT est un équipement fondamental dans la fabrication, assemblée, et opérations de stockage. La caractéristique déterminante d'une grue EOT est qu'elle fonctionne sur un système de piste fixe, généralement constitué de deux poutres parallèles (rails de piste) fixé à la structure porteuse du bâtiment.

La grue elle-même « voyage » le long de ces rails, couvrant toute la longueur de la baie, tandis qu'un mécanisme de levage se déplace sur le pont de la grue, couvrant la largeur. Cette combinaison de mouvements permet à la grue de desservir pratiquement tous les points de sa zone de travail rectangulaire..

10 Grue EOT en tonnes

Les grues EOT sont principalement classées en fonction de leur structure de pont et du nombre de poutres qu'elles utilisent.. Les deux types les plus courants sont:

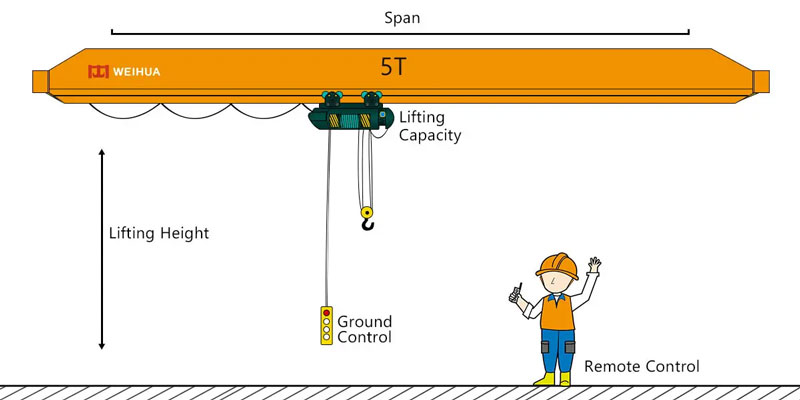

5 Grue EOT à poutre unique de tonnes

UN Grue EOT monopoutre comporte une poutre de pont principale sur laquelle le palan et chariot fonctionner. Le palan est généralement monté sur un chariot qui se déplace le long de la semelle inférieure de la poutre..

Caractéristiques clés:

Idéal pour: Cycles de service plus légers à modérés, capacités généralement jusqu'à 20 tonnes, et les applications où le coût et la marge sont des préoccupations majeures. Courant dans les ateliers, entrepôts, et des usines de fabrication plus petites.

Une grue EOT bipoutre est construite avec deux poutres de pont principales qui soutiennent le chariot et le palan. Le chariot roule sur des rails montés au dessus des deux poutres.

Caractéristiques clés:

Idéal pour: Applications lourdes, utilisation fréquente, capacités élevées, aciéries, fonderies, centrales électriques, et ports maritimes à grande échelle.

Top-running contre. Sous-fonctionnement: Cela fait référence à la façon dont la grue se déplace sur la piste. Des grues performantes (décrit ci-dessus) rouler sur des rails au sommet des poutres de la piste. Sous-fonctionnement (ou sous-suspendu) les grues ont des chariots d'extrémité qui suspendent la grue à la semelle inférieure des poutres de roulement.

Grue à portique: Une variante où le pont est soutenu par deux ou plusieurs pieds fonctionnant sur des rails fixes au niveau du sol, au lieu d'être attaché à une structure de bâtiment. Il s’agit essentiellement d’une grue EOT « autoportante ».

application

Les grues EOT sont les bêtes de somme de l'industrie lourde en raison de leur efficacité et de leur fiabilité.. Leurs principaux scénarios d'application incluent:

En résumé, que vous ayez besoin d'une grue EOT monopoutre économique pour les tâches légères ou d'une grue EOT bipoutre robuste pour les tâches lourdes, applications intensives, cette solution de manutention est conçue pour améliorer la productivité, améliorer la sécurité, et rationalisez vos opérations.

Nous apprécions vos commentaires! Veuillez remplir le formulaire ci-dessous afin que nous puissions adapter nos services à vos besoins spécifiques.

Designed specifically for the rigorous demands of metal processing, automotive manufact……

Découvrir plus →

Les portiques à conteneurs sont l'épine dorsale de la logistique mondiale, permettant un chargement efficace……

Découvrir plus →

A grab bucket overhead crane is a specialized material handling machine designed to str……

Découvrir plus →

Cliquez sur le bouton pour obtenir des informations et des citations de produits sur WhatsApp.

Obtenez un devis

Dernières commentaires