Le tambour de câble métallique de grue est un composant essentiel à la mission conçu pour l'enroulement sûr et efficace du câble métallique sur différents types de grues..

Le tambour de câble métallique de grue sert de noyau au levage et, dans certains cas, le mécanisme de déplacement, impactant directement la capacité de levage de la grue, fluidité opérationnelle, et la sécurité globale. Fabriqué en acier à haute résistance et conçu selon des spécifications précises, nos tambours à câble sont conçus pour résister à des charges extrêmes, résister à l'usure, et fournir un service fiable sur une longue durée de vie opérationnelle dans des environnements industriels exigeants.

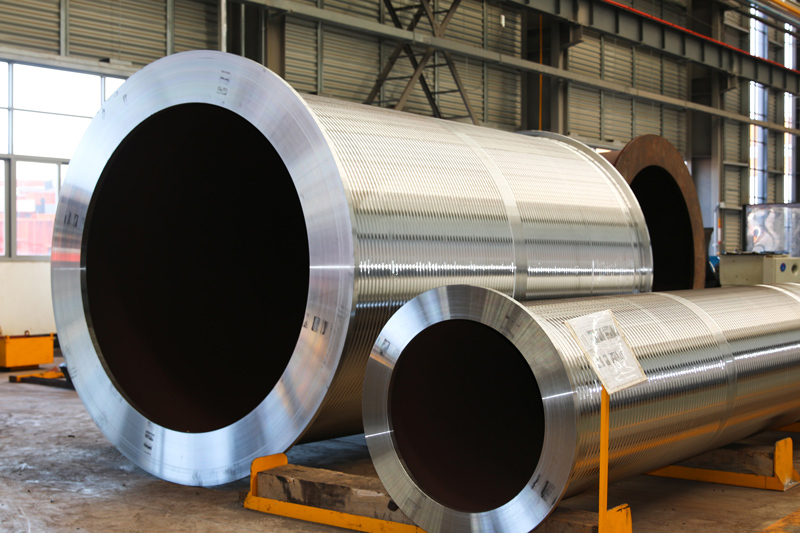

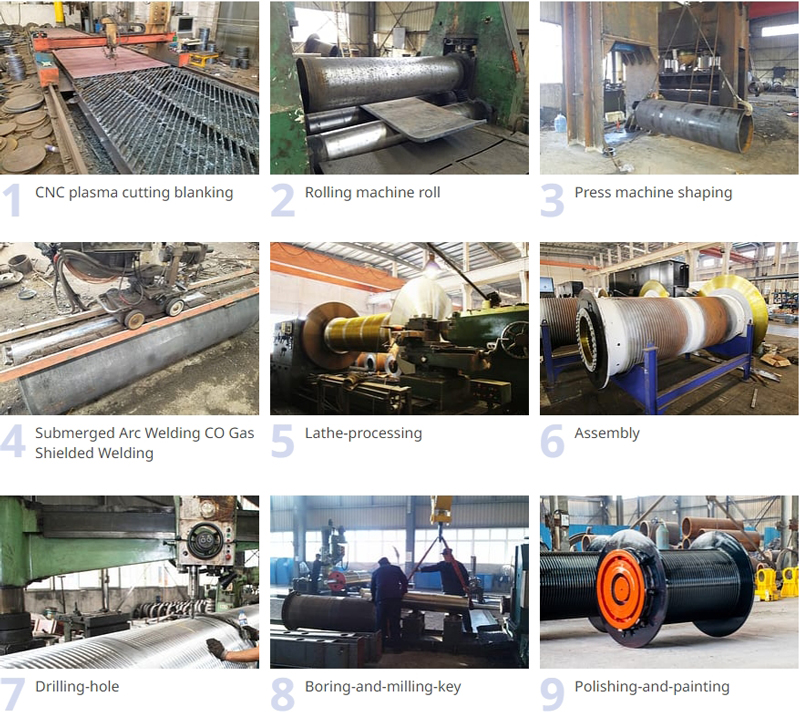

1. Construction robuste & Matériaux premium

Fabriqué à partir de pièces forgées en acier au carbone ou en acier allié à haute limite d'élasticité.

Conçu avec une épaisseur de paroi et une intégrité structurelle optimales pour supporter des charges nominales maximales et éviter la déformation.

2. Rainures usinées avec précision

Les rainures du câble sont méticuleusement usinées pour correspondre au diamètre spécifique du câble métallique.

Garantit un enroulement correct, minimise l'usure et l'écrasement du câble, et prolonge la durée de vie du tambour et de la corde.

3. Conception de bride avancée

Les brides sont conçues avec une hauteur suffisante pour contenir plusieurs couches de corde en toute sécurité, prévenir le dépassement de la corde et les accidents potentiels.

Les bords arrondis et lisses des brides protègent le câble métallique des dommages pendant le fonctionnement.

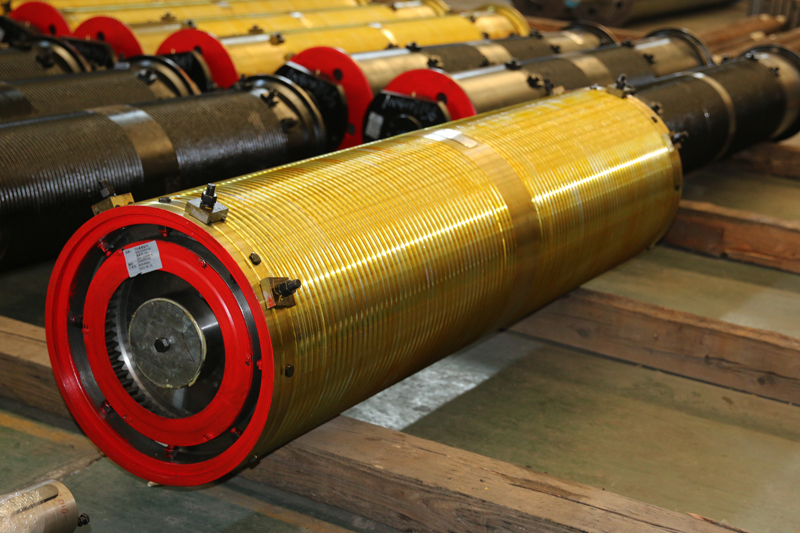

4. Durée de vie durable & Traitement de surface

Les fûts subissent des processus de traitement thermique spécialisés (comme la trempe et le revenu) pour améliorer la dureté de la surface et la résistance à la fatigue.

Des revêtements de protection en option, comme la galvanisation ou des systèmes de peinture spécialisés, sont disponibles pour une résistance supérieure à la corrosion dans les environnements difficiles. (Par exemple, marin, chimique).

5. Connexion optimisée & Montage

Conçu pour une intégration transparente avec les accouplements à engrenages, arbres cannelés, ou systèmes à entraînement direct.

Les points de montage usinés avec précision assurent un alignement parfait avec la boîte de vitesses et le moteur, réduisant les vibrations et les contraintes mécaniques.

6. Capacité de mise en file d'attente multicouche

Conçu pour un enroulement multicouche fluide et contrôlé, ce qui est indispensable pour les grues nécessitant des hauteurs de levage élevées sans un diamètre de tambour trop important.

Note: Le tableau suivant fournit une plage de spécifications générales. Les tambours personnalisés sont notre spécialité.

| Paramètre | Spécification | Notes |

|---|---|---|

| Diamètre du noyau du tambour | 200 mm - 2,000 MM | Diamètres personnalisés disponibles en fonction de la taille du câble et de l'application. |

| Longueur du tambour | 500 mm - 6,000 MM | Déterminé par la longueur de la corde, nombre de chutes, et couches. |

| Plage de diamètre de corde | 8 mm - 60 MM | Les rainures sont usinées pour correspondre au diamètre de corde spécifié. |

| Hauteur de bride | Standard: 1.5 x Diamètre de la corde Multicouche: Selon la conception |

Assure un confinement sûr de la corde. |

| Capacité maximale de la corde | Jusqu'à 1,000+ mètres | Varie selon les dimensions du tambour et les couches de bobinage. |

| Limite de chargement de travail (Wll) | 1 Tonne – 500+ Tonnes | Conçu avec un facteur de sécurité dépassant les normes de l'industrie (Par exemple, Femelle, DEPUIS). |

| Type de montage | Bride simple ou double | Accouplement à engrenages, Arbre cannelé, ou entraînement direct. |

| Qualité du matériau | Q235B, Q345B, AISI 4140, ou acier à haute résistance équivalent. | |

| Traitement de surface | Tir soufflé, Peint (Standard), Galvanisé (Facultatif) |

Nos tambours à câble sont polyvalents et peuvent être personnalisés pour un large éventail d'applications de grues., y compris, mais sans s'y limiter:

Q1: Comment sélectionner le tambour à câble adapté à ma grue?

UN: La sélection dépend de plusieurs facteurs: la capacité de levage maximale de la grue, le diamètre du câble métallique, la longueur de corde requise (tambour), le nombre de couches de mise en file d'attente, et le cycle de fonctionnement. Il est fortement recommandé de consulter notre équipe d’ingénierie avec les spécifications de votre grue.

Q2: Pouvez-vous fabriquer un tambour de remplacement pour mon modèle de grue ancien ou obsolète?

UN: Absolument. Nous sommes spécialisés dans la rétro-ingénierie et la fabrication de pièces de rechange sur mesure. Fournissez-nous les dessins originaux, ou nous pouvons prendre des mesures précises à partir de votre tambour existant pour créer un parfait, remplacement haute performance.

Q3: À quelle fréquence le tambour de câble doit-il être inspecté?

UN: Des inspections visuelles doivent être effectuées avant chaque quart de travail. Un formel, une inspection détaillée doit être effectuée mensuellement ou selon le calendrier de maintenance de votre grue et conformément aux réglementations de sécurité locales (Par exemple, OSHA, LOLER). Les éléments clés à vérifier sont l'usure des rainures, fissure, et l'intégrité de la bride.

T4: Quels sont les signes indiquant qu'un tambour à câble doit être remplacé?

UN: Les signes courants incluent:

Usure excessive dans les rainures du câble, créant un bord tranchant qui endommage la corde.

Fissures ou déformations visibles sur le fût ou les brides du tambour.

Le tambour est déformé ou a été soumis à un événement de surcharge.

Q5: Proposez-vous un durcissement de surface pour les rainures du câble ??

UN: Oui, nous proposons en option un durcissement par induction ou un chromage dur pour les rainures du câble. Cela augmente considérablement la résistance à l'usure et est idéal pour les applications à cycle de service élevé.

Pour plus de spécifications techniques, devis personnalisés, ou support technique, veuillez contacter notre équipe commerciale.

Nous apprécions vos commentaires! Veuillez remplir le formulaire ci-dessous afin que nous puissions adapter nos services à vos besoins spécifiques.

Avec une construction robuste et une technologie d'entraînement électrique avancée, 10 tonnes palan électrique ……

Découvrir plus →

A shop overhead crane, also known as an industrial overhead crane or bridge crane, is a……

Découvrir plus →

Le 200 Le pont roulant de tonnes est un équipement de levage robuste conçu pour répondre aux dema……

Découvrir plus →

Cliquez sur le bouton pour obtenir des informations et des citations de produits sur WhatsApp.

Obtenez un devis

Dernières commentaires