In the high-stakes world of material handling, levage, et logistique, guesswork is not an option. Knowing the exact weight of a load isn’t just about efficiency—it’s about safety, compliance, and protecting your bottom line. This is where the unsung hero of modern lifting operations comes into play: the Crane Hook Weighing System.

Gone are the days of relying on vague estimates or separate, time-consuming static scales. Today’s technology integrates weighing directly into the most critical point of the lift: le crochet. Let’s dive into what these systems are, comment ils fonctionnent, and why they might be the most impactful upgrade for your facility.

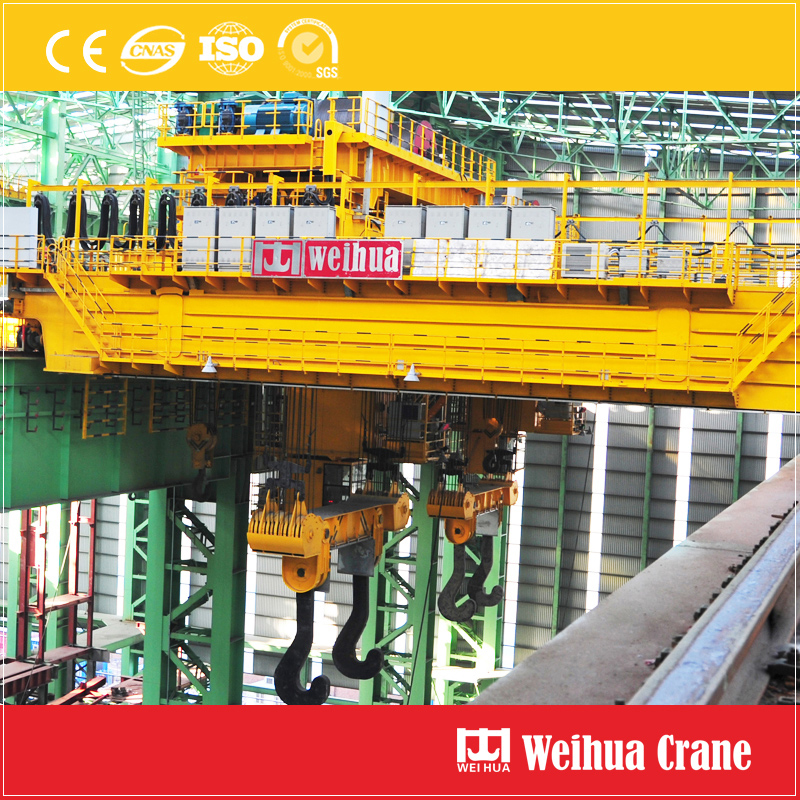

A crane hook weighing system is an integrated solution that allows operators to measure the weight of a load in real-time, directly from the crane itself. It typically consists of a robust, high-capacity load cell or force sensor built into the crane’s hook, manille, or sheave. This sensor is connected to a digital indicator (often mounted in the cab or a handheld remote) that displays the weight clearly and accurately.

It’s essentially a precision scale designed to operate in the toughest industrial environments, providing critical data at the moment it’s needed most.

The principle is elegant in its simplicity:

Advanced systems can also log this data, set overload alarms, and integrate with warehouse management software for seamless inventory tracking.

Investing in a hook weighing system delivers a powerful return on investment across several key areas:

Crane hook weighing systems are versatile and are used across a wide range of industries:

| Fabrication & Aciéries | Handling raw materials, bobine, and finished goods. |

| Expédition & Logistique | Loading and unloading containers and verifying shipment weights. |

| Scrap Metal & Recycling | Weighing unpredictable and valuable loads for sale and inventory. |

| Construction | Lifting pre-cast concrete elements, machinerie, and building materials. |

| Exploitation minière & Quarrying | Moving heavy ore, rochers, et l'équipement. |

When considering a system, think about:

A crane hook weighing system transforms a standard crane into an intelligent, data-driven lifting machine. It moves weight measurement from a separate, manual task to an integrated, automated function that happens seamlessly within the workflow.

For any business where lifting is core to operations, it’s not just an accessory—it’s a fundamental tool for fostering a culture of safety, driving efficiency, and achieving a new level of operational control.

Q1: How accurate are crane hook weighing systems?

A1: Modern systems are highly accurate, typically within ±0.1% to ±1% of the full scale value, depending on the quality of the load cell and system calibration. Par exemple, a 100-ton capacity system with ±0.5% accuracy is accurate to within ±1000 lbs. High-precision models are available for applications where exact weight is critical for trade or (formulation).

Q2: Can they be installed on any type of crane?

A2: Oui, virtually. These systems are incredibly versatile and can be configured for:

Q3: What’s the difference between a wired and wireless system?

A2:

T4: Are these systems rugged enough for harsh environments?

A4: Absolument. Reputable manufacturers build systems with robust enclosures that have high Ingress Protection (IP) ratings (Par exemple, IP65, IP67) for resistance against dust and water. For extreme environments like steel mills or foundries, systems are available with special heat shields to protect the load cell from radiant heat.

Nous apprécions vos commentaires! Veuillez remplir le formulaire ci-dessous afin que nous puissions adapter nos services à vos besoins spécifiques.

Cliquez sur le bouton pour obtenir des informations et des citations de produits sur WhatsApp.

Obtenez un devis

Dernières commentaires