The electric hoist hook is a key component in lifting equipment and is responsible for directly suspending and carrying heavy objects. The electric hoist hook is a hook device developed by Weihua Group for small and medium-sized lifting equipment. It can handle goods ranging from 0.5 tons to 50 tons.

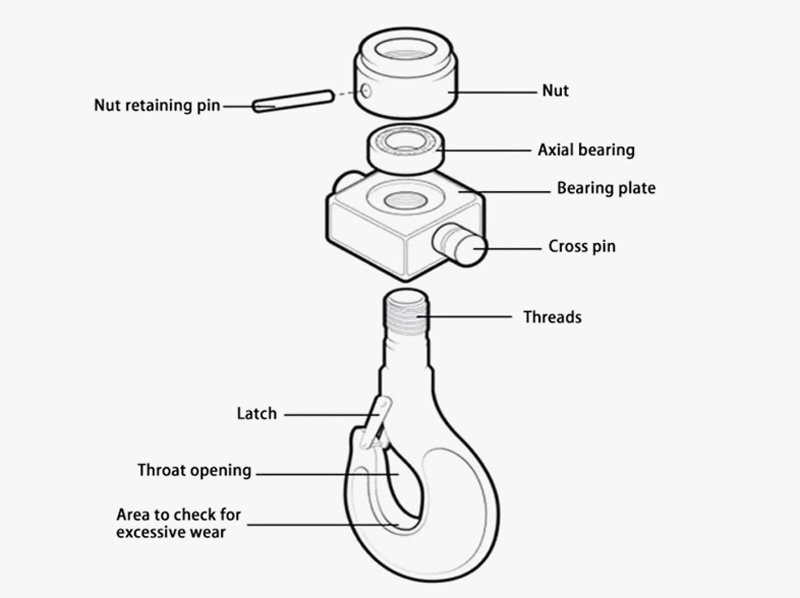

The electric hoist hook consists of a hook body, a lock, a bearing or rotating mechanism, and a hook nut/pin. The hook body structure of the Weihua electric hoist hook is forged or rolled from high-strength alloy steel, which has high toughness and fatigue resistance.

Single hook (straight handle hook): simple structure, suitable for light loads.

Double hook (S-shaped hook): symmetrical design, better balance, suitable for medium-sized loads.

Hook with safety lock: Equipped with a spring lock or latch to prevent unhooking (complying with safety standards).

| Parameter category | Parameter description |

| Rated load | – Common range: 0.5 tons ~ 50 tons (needs to match the rated load of the electric hoist) – Safety factor: generally 4 to 6 times (for example, for a hook rated 1 ton, the ultimate breaking force needs to be 4 to 6 tons) |

| Materials and craftsmanship | – Material: Alloy steel (35CrMo, 20Mn2), stainless steel (304/316, used in corrosive environments) – Process: forging (high strength), rolling (economical) |

| Hook type | – Single hook (straight handle hook): light load (0.5~5 tons) – Double hook (S-shaped hook): medium load (5 to 20 tons) – Rotating hook: heavy load (10~50 tons) |

| Critical dimensions | – Hook mouth width (D): determines the size of the spreader that can be hung (such as 20mm ~ 200mm) – Hook body diameter (d): Positively related to load (for example, 1 ton hook d≈20mm) – Total height (H): affects the working space (usually 200mm ~ 800mm) |

| Rotate function | – Rotation angle: 360° free rotation – Rotation speed: ≤2r/min (with ball bearings or sliding bearings) |

| Safety device | – Crane hook safety latch types: spring lock, latch lock, flip lock – Lock opening and closing force: ≤10N (to avoid accidental opening) |

| Environmental adaptability | – Temperature range: -20℃~+200℃ (high temperature requires special heat treatment) – Anti-corrosion grade: ordinary (carbon steel), IP65 (dustproof and waterproof), stainless steel (acid and alkali resistant) |

Load limit:

Overloading is strictly prohibited and the load must not exceed the rated lifting capacity marked on the hook.

Avoid impact loads and lift slowly and steadily.

Daily inspection:

Cracks or deformation: Check the hook body and lock buckle for cracks, bends or wear before use.

Degree of wear: If the wear of the hook tip exceeds 10% of the original size, it needs to be replaced.

Rotational flexibility: The rotating hook should ensure smooth rotation without jamming.

Correct hanging:

The center of gravity of the load should be located at the center of the hook. It is prohibited to pull diagonally, pull sideways or tie it loosely.

When using a sling/rope, make sure it is fully embedded in the bottom of the hook to avoid getting caught on the hook tip.

Environmental adaptability:

High temperature and corrosive environments require the use of special materials (such as stainless steel hooks).

Avoid use near live lines to prevent risk of electric shock.

Cleaning and Lubrication:

Clean dust and oil regularly to prevent impurities from exacerbating wear and tear.

The rotating parts need to be filled with high temperature resistant grease to maintain flexibility.

Anti-corrosion treatment:

In humid or corrosive environments, apply anti-rust oil or galvanize.

Regular testing:

Conduct magnetic particle inspection or ultrasonic inspection every 6 months to check for internal defects.

Check whether connecting parts (such as pins, nuts) are loose or deformed.

Replacement standards:

When cracks, permanent deformation, or the hook mouth expands by more than 15%, it must be replaced immediately.

The lock fails or the spring loses its elasticity and needs to be repaired or replaced.

Q: The hook is not flexible in rotation.

A: Check whether the bearing is short of oil or foreign matter has entered, and lubricate it after cleaning.

Q: Lock cannot be closed.

A: Check whether the spring is damaged or the locking mechanism is deformed.

Q: Rust on hook body surface.

A: Mild rust can be polished with sandpaper and then coated with anti-rust oil; severe rust requires replacement.

Q: How to understand the “safety factor 4 times” of the hook?

A: The breaking strength of the hook needs to be more than 4 times the rated load (for example, a 1-ton hook needs to withstand 4 tons of pulling force without damage).

Q: How to judge whether the hook needs to be replaced?

A: Deformation of the hook mouth leads to an increase in width of ≥15%;

Surface crack depth ≥1mm;

The hook tip wear exceeds 10% of the original thickness.

Q: How long is the bearing life of a swivel hook?

A: It lasts about 5,000 hours under normal working conditions and requires lubrication and maintenance every 3 months.

We value your feedback! Please complete the form below so that we can tailor our services to your specific needs.

The 60 tons crane hook is a critical lifting component engineered for heavy-duty indust……

Discover More →

Product Varieties & Specifications Electromagnetic Lifting Magnets are primarily cat……

Discover More →

Replace manual rigging, clamps, and grabs with intelligent magnetic force. Our Electroma……

Discover More →

Latest Comments