یک تیر دوگانه EOT (سفر سربار برقی) crane is a robust, overhead lifting system designed for heavy-duty material handling in industrial environments.

یک تیر دوگانه EOT (سفر سربار برقی) crane is a robust, overhead lifting system designed for heavy-duty material handling in industrial environments. Unlike single girder EOT crane, it features two parallel main girders spanning the workspace, supported by end carriages that travel along elevated runways. This structure enables it to handle significantly higher loads—typically ranging from 10 تن به 500 tons or more—making it ideal for demanding lifting tasks where precision, ثبات, and durability are critical.

Powered by an electric motor, the double girder EOT crane operates via a hoist (mounted on a trolley) that moves along the girders, combined with runway travel for full coverage of the workspace. It is widely recognized as a reliable solution for streamlining operations in factories, انبارها, and heavy industries.

Double girder EOT cranes stand out for their advanced design and performance, offering the following advantages:

|

پارامتر

|

Range/Details

|

|

ظرفیت بار نامی

|

10t–500t+ (customizable for ultra-heavy loads)

|

|

طول دهانه

|

10m–35m (longer spans available with structural reinforcement)

|

|

ارتفاع بلند کردن

|

6m–30m (adjustable based on workspace height)

|

|

طبقه کارگر

|

A5–A8 (استاندارد ISO; A8 for continuous heavy-duty operations)

|

|

سرعت بالابر

|

0.5m/min–10m/min (variable frequency control for smooth speed adjustment)

|

|

سرعت سفر واگن برقی

|

10m/min–40m/min

|

|

سرعت سفر جرثقیل

|

20m/min–60m/min

|

|

منبع تغذیه

|

380V/50Hz (customizable for 220V/60Hz or other voltages)

|

|

حالت کنترل

|

کنترل آویز, کنترل از راه دور بی سیم, یا کنترل کابین

|

|

ویژگی های ایمنی

|

محافظت بیش از حد, سوئیچ های محدود, توقف اضطراری, anti-collision devices

|

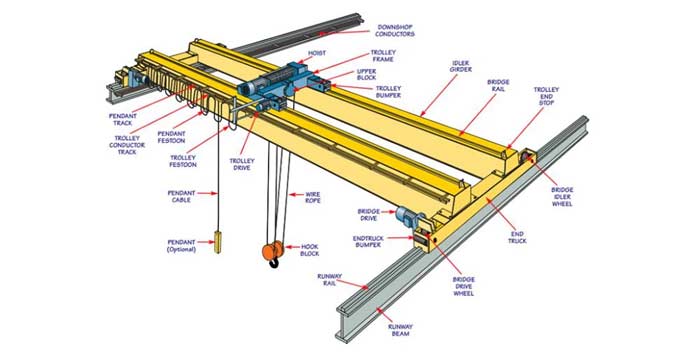

A double girder EOT crane consists of several key components working together to ensure reliable lifting:

Two parallel box-type or I-beam steel girders forming the primary load-bearing structure, spanning the workspace.

Located at both ends of the main girders, equipped with wheels that travel along the runway rails, enabling the crane to move horizontally.

The hoist (electric winch with hook, آهنربا, or grab) is mounted on a trolley, which travels along the main girders via rails, allowing vertical lifting and horizontal movement along the span.

Elevated rails (installed on columns or walls) that guide the crane’s end carriages, defining the crane’s travel range.

Includes motors (بالابر, واگن برقی, crane travel), control panels, کابل ها, and safety devices (overload sensors, سوئیچ های محدود) to manage power and operations.

Double girder EOT cranes are indispensable in industries requiring heavy lifting and precise material handling:

Q1: What’s the difference between a double girder and single girder EOT crane?

الف: Double girder cranes have two main girders, offering higher load capacity (10t+) and stability, suitable for heavy-duty use. Single girder cranes have one girder, ideal for lighter loads (up to 20t) and smaller workspaces.

Q2: How often should a double girder EOT crane be maintained?

الف: بازرسی های معمول (daily checks for wear, monthly lubrication) and annual professional maintenance are recommended to ensure safety and extend service life.

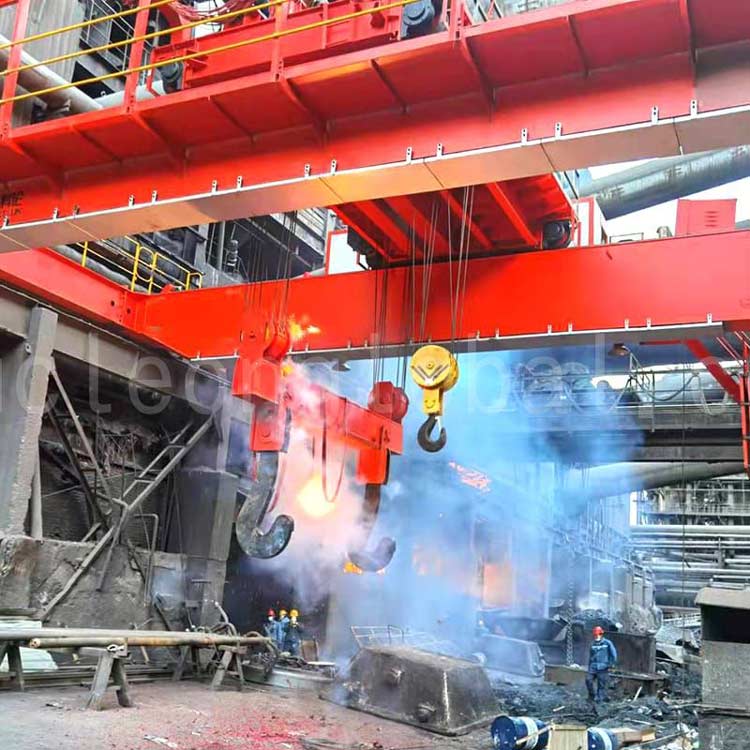

Q3: Can double girder EOT cranes be customized for special environments?

الف: بله. Options include explosion-proof designs (for hazardous areas), corrosion-resistant coatings (for chemical plants), and high-temperature resistance (for foundries).

Q4: What safety standards do double girder EOT cranes comply with?

الف: They adhere to international standards such as ISO, زن, از, and OSHA, with built-in safety features like overload protection and emergency stops.

Q5: How long does it take to install a double girder EOT crane?

الف: Installation time varies by size and complexity—typically 2–4 weeks for standard models, with longer timelines for custom or large-span systems.

Whether you need to lift heavy machinery in a factory or handle bulk materials in a port, our double girder EOT cranes deliver the strength, precision, and reliability to optimize your operations. Contact us for a custom solution tailored to your needs.

با PDF به اشتراک بگذارید: دانلود کنید

ما برای بازخورد شما ارزش قائل هستیم! لطفاً فرم زیر را تکمیل کنید تا بتوانیم خدمات خود را متناسب با نیازهای خاص شما تنظیم کنیم.

به عنوان یک تولید کننده جرثقیل دروازه ای دو تیرچه پیشرو, گروه WEIHUA قوی ارائه می دهد, به خاطر……

بیشتر کشف کنید →

جرثقیل های دروازه ای کانتینری ستون فقرات لجستیک جهانی هستند, enabling efficient loading……

بیشتر کشف کنید →

تقاضای عملیات ریخته گری ناهموار است, تجهیزات بالابری قابل اعتماد که می توانند در برابر سختی ها مقاومت کنند…

بیشتر کشف کنید →

برای به دست آوردن اطلاعات محصول و نقل قول های موجود در WhatsApp روی دکمه کلیک کنید.

نقل قول

آخرین نظرات