The electric hoist hook is a key component in lifting equipment and is responsible for directly suspending and carrying heavy objects. The electric hoist hook is a hook device developed by Weihua Group for small and medium-sized lifting equipment. It can handle goods ranging from 0.5 تن به 50 تن.

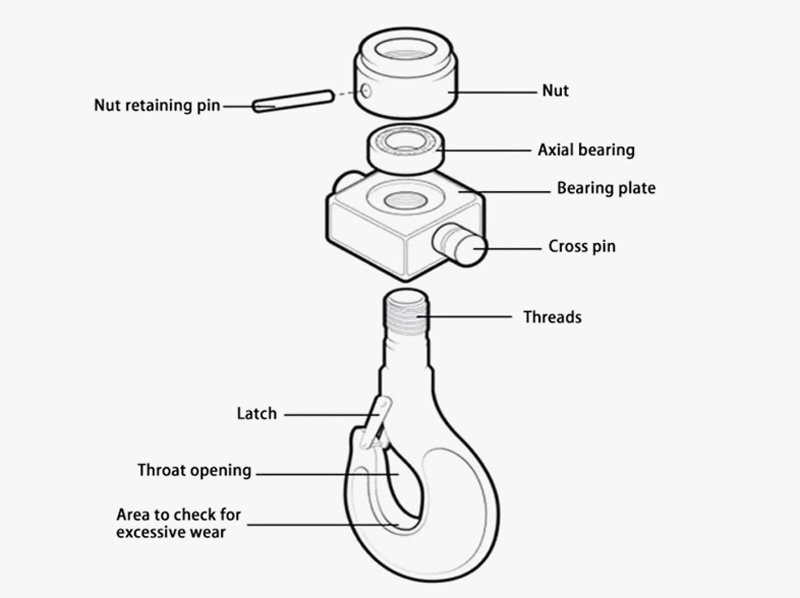

قلاب بالابر برقی از بدنه قلاب تشکیل شده است, یک قفل, a bearing or rotating mechanism, and a hook nut/pin. The hook body structure of the Weihua electric hoist hook is forged or rolled from high-strength alloy steel, which has high toughness and fatigue resistance.

قلاب (straight handle hook): ساخت ساده, suitable for light loads.

قلاب دوبل (قلاب S شکل): symmetrical design, better balance, suitable for medium-sized loads.

Hook with safety lock: Equipped with a spring lock or latch to prevent unhooking (complying with safety standards).

| Parameter category | Parameter description |

| بار نامی | – Common range: 0.5 tons ~ 50 تن (needs to match the rated load of the electric hoist) – Safety factor: generally 4 به 6 times (به عنوان مثال, for a hook rated 1 تن, the ultimate breaking force needs to be 4 به 6 تن) |

| Materials and craftsmanship | – Material: فولاد آلیاژی (35CRMO, 20Mn2), فولاد ضد زنگ (304/316, used in corrosive environments) – Process: جعل (high strength), rolling (economical) |

| Hook type | – Single hook (straight handle hook): light load (0.5~5 tons) – Double hook (قلاب S شکل): medium load (5 به 20 تن) – Rotating hook: heavy load (1050 تن پوند) |

| Critical dimensions | – Hook mouth width (د): determines the size of the spreader that can be hung (such as 20mm ~ 200mm) – Hook body diameter (د): Positively related to load (به عنوان مثال, 1 ton hook d≈20mm) – Total height (اچ): affects the working space (usually 200mm ~ 800mm) |

| تابع چرخش | – Rotation angle: 360° چرخش رایگان – Rotation speed: ≤2r/min (with ball bearings or sliding bearings) |

| Safety device | - Crane hook safety latch انواع: spring lock, latch lock, flip lock – Lock opening and closing force: ≤10N (to avoid accidental opening) |

| سازگاری محیطی | – Temperature range: -20℃~+200℃ (high temperature requires special heat treatment) – Anti-corrosion grade: ordinary (carbon steel), IP65 (dustproof and waterproof), فولاد ضد زنگ (acid and alkali resistant) |

Load limit:

Overloading is strictly prohibited and the load must not exceed the rated lifting capacity marked on the hook.

Avoid impact loads and lift slowly and steadily.

بازرسی روزانه:

ترک یا تغییر شکل: Check the hook body and lock buckle for cracks, bends or wear before use.

Degree of wear: If the wear of the hook tip exceeds 10% of the original size, it needs to be replaced.

Rotational flexibility: The rotating hook should ensure smooth rotation without jamming.

Correct hanging:

The center of gravity of the load should be located at the center of the hook. It is prohibited to pull diagonally, pull sideways or tie it loosely.

When using a sling/rope, make sure it is fully embedded in the bottom of the hook to avoid getting caught on the hook tip.

سازگاری محیطی:

High temperature and corrosive environments require the use of special materials (such as stainless steel hooks).

Avoid use near live lines to prevent risk of electric shock.

Cleaning and Lubrication:

Clean dust and oil regularly to prevent impurities from exacerbating wear and tear.

The rotating parts need to be filled with high temperature resistant grease to maintain flexibility.

Anti-corrosion treatment:

In humid or corrosive environments, apply anti-rust oil or galvanize.

Regular testing:

Conduct magnetic particle inspection or ultrasonic inspection every 6 months to check for internal defects.

Check whether connecting parts (such as pins, آجیل) are loose or deformed.

Replacement standards:

When cracks, permanent deformation, or the hook mouth expands by more than 15%, باید بلافاصله جایگزین شود.

The lock fails or the spring loses its elasticity and needs to be repaired or replaced.

س: The hook is not flexible in rotation.

الف: Check whether the bearing is short of oil or foreign matter has entered, and lubricate it after cleaning.

س: Lock cannot be closed.

الف: Check whether the spring is damaged or the locking mechanism is deformed.

س: Rust on hook body surface.

الف: Mild rust can be polished with sandpaper and then coated with anti-rust oil; severe rust requires replacement.

س: How to understand the “safety factor 4 times” of the hook?

الف: The breaking strength of the hook needs to be more than 4 times the rated load (به عنوان مثال, a 1-ton hook needs to withstand 4 tons of pulling force without damage).

س: How to judge whether the hook needs to be replaced?

الف: Deformation of the hook mouth leads to an increase in width of ≥15%;

Surface crack depth ≥1mm;

The hook tip wear exceeds 10% of the original thickness.

س: How long is the bearing life of a swivel hook?

الف: It lasts about 5,000 hours under normal working conditions and requires lubrication and maintenance every 3 ماه ها.

ما برای بازخورد شما ارزش قائل هستیم! لطفاً فرم زیر را تکمیل کنید تا بتوانیم خدمات خود را متناسب با نیازهای خاص شما تنظیم کنیم.

ویژگی های کلیدی جرثقیل جابجایی سیم پیچ استحکام بالا & ثبات: سیم پیچ Weihua h……

بیشتر کشف کنید →

در 30 قلاب جرثقیل تن تولید شده توسط Weihua Group تجهیزات اصلی جرثقیل سنگین است ...

بیشتر کشف کنید →

The Single Girder Crane Hook is the critical endpoint of your overhead lifting system, d……

بیشتر کشف کنید →

برای به دست آوردن اطلاعات محصول و نقل قول های موجود در WhatsApp روی دکمه کلیک کنید.

نقل قول

آخرین نظرات