High-performance slab/billet cranes for steel mill with customizable lifting spreaders (mechanical clamp & electromagnetic). Features high-temperature resistance, control preciso & comprehensive safety.

Slab/billet cranes for steel mill are specialized lifting equipment meticulously designed to meet the rigorous demands of steel production environments. Tailored for the safe and efficient handling of slabs and billets—core semi-finished products in steel manufacturing—these cranes serve as the backbone of material flow in steel mills, connecting key processes such as continuous casting, heating furnace charging, rolling mill feeding, and finished product storage. Engineered to withstand extreme conditions including high temperatures, heavy dust, and frequent shock loads, our slab/billet cranes for steel mill ensure stable, confiable, and high-performance operation, directly contributing to the improvement of production efficiency and safety in steel plants.

|

Parámetro

|

Rango

|

|---|---|

|

Capacidad de levantamiento

|

5t – 300t

|

|

Durar

|

10m-35m

|

|

Altura de elevación

|

6m-30m

|

|

Velocidad de elevación

|

0.5m/minuto – 10m/minuto (adjustable by frequency conversion)

|

|

Traversing Speed

|

5m/minuto – 30m/minuto (adjustable by frequency conversion)

|

|

Clase trabajadora

|

A6 – A8 (heavy-duty/extra-heavy-duty)

|

|

Temperatura ambiente

|

-20°C – 1000°C (with high-temperature protection)

|

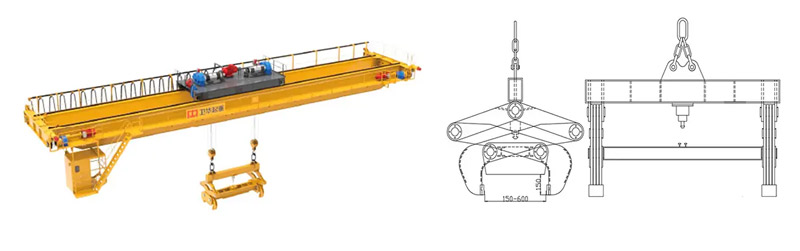

The lifting spreader is a critical core component of slab/billet cranes for steel mill, directly determining the stability, seguridad, and efficiency of material handling. We equip our cranes with two types of professional spreaders, customizable according to different steel mill scenarios and material characteristics to maximize the performance of slab/billet cranes for steel mill.

This spreader adopts a precision mechanical linkage structure, which realizes automatic clamping and releasing of slabs/billets through the gravity of the load and the tension of the crane’s lifting mechanism. Its key advantages include:

Ideal for handling thin slabs, small billets, or scenarios requiring frequent loading and unloading, the electromagnetic spreader uses electromagnetic force to adsorb and lift materials. Its prominent features are:

1. High Temperature Resistance & Durabilidad

2. Control de precisión & Alta eficiencia

3. Protección de seguridad integral

4. Diseño personalizable

Our slab/billet cranes for steel mill are widely used in various key links of steel mills, incluido: these scenarios fully demonstrate the versatility and reliability in steel production.

We provide a full-cycle after-sales service system for our slab/billet cranes: professional technical team on-site installation and commissioning; regular maintenance and inspection services; 24/7 emergency repair support; and training for the customer’s operation and maintenance personnel. We are committed to ensuring that the slab/billet cranes for steel mill operate at peak performance for a long time, providing reliable support for the smooth production of steel mills.

For more detailed product information, customized solutions, or quotation inquiries about slab/billet cranes for steel mill, por favor contacte a nuestro equipo de ventas. We will respond to your needs promptly with professional services.

Compartir con PDF: Descargar

Valoramos sus comentarios! Complete el formulario a continuación para que podamos adaptar nuestros servicios a sus necesidades específicas..

La grúa puente metalúrgica de dos vigas es un equipo de elevación especializado……

Descubre más →

Descripción general del producto el 40 tons double girder overhead crane is a heavy-duty material han……

Descubre más →

As a professional heavy-duty material handling equipment, el 70 tons overhead crane is……

Descubre más →

Haga clic en el botón para obtener información del producto y cotizaciones en WhatsApp.

Obtener una cotización

Últimos comentarios