Professional electrolytic aluminum overhead crane designed for harsh workshop environments (temperatura alta, polvo, corrosión). Features heavy-load capacity (5t-200t), high-temperature resistance, multi-layer safety protection & customizable design, ideal for electrolytic/casting workshops to boost efficiency & ensure stable operation.

As a core lifting equipment specially designed for the electrolytic aluminum production process, the electrolytic aluminum overhead crane is engineered to adapt to the harsh working environment of electrolytic aluminum workshops—high temperature, polvo, corrosive gas, and heavy-load continuous operation. It integrates stability, seguridad, y eficiencia, providing reliable lifting and transportation support for each link of electrolytic aluminum production, from raw material feeding to electrolytic cell maintenance, and finished product handling.

Electrolytic Aluminum Overhead Crane

The electrolytic aluminum overhead crane is a customized heavy-duty lifting equipment developed for the special working conditions of electrolytic aluminum plants. Different from ordinary puentes grúa, it adopts special materials, sealing structures and safety protection systems to resist the erosion of high temperature (up to 600℃), corrosive electrolyte vapor and dust, ensuring long-term stable operation in harsh environments. It is mainly used in electrolytic workshops, talleres de fundición, and auxiliary workshops of electrolytic aluminum enterprises, undertaking tasks such as lifting aluminum ingots, anode blocks, cathode plates, electrolytic cell components, and molten aluminum ladles (matched with special spreaders).

With the core advantages of high load-bearing capacity, posicionamiento preciso, strong corrosion resistance and high safety, this series of overhead cranes can effectively improve production efficiency, reduce labor intensity, and ensure the smooth progress of electrolytic aluminum production, which is an indispensable key equipment in the modern electrolytic aluminum industry.

1. High-Temperature & Resistencia a la corrosión

The main structural parts (haz, carretilla, viga final) are made of high-temperature resistant alloy steel, and the surface is treated with anti-corrosion and high-temperature resistant coating, which can effectively resist the damage of high-temperature radiation and corrosive gas in the electrolytic workshop. The electrical components are equipped with high-temperature resistant protective covers, and the sealing performance is optimized to prevent dust and electrolyte vapor from entering, ensuring the normal operation of electrical systems.

2. Heavy-Load Design & Stable Operation

According to the actual needs of electrolytic aluminum production, it is designed with a heavy-duty structure, with a rated lifting capacity of 5t-200t and a span of 10m-35m (customizable according to workshop size). The lifting mechanism adopts a high-torque motor and a hard-tooth surface reducer, which has the characteristics of stable transmission, low noise and strong overload capacity. The running mechanism adopts frequency conversion speed regulation technology, which realizes smooth start and stop, reduces impact, and ensures precise positioning of lifting objects (Precisión de posicionamiento de hasta ±5 mm.).

3. Multi-Layer Safety Protection

Safety is the top priority of electrolytic aluminum production. This electrolytic aluminum overhead crane is equipped with a complete set of safety protection devices, incluido: overload protection device (automatically cut off power when overloaded), interruptor de límite (lifting and running limit, preventing overtravel), anti-collision device (avoiding collision between cranes or between cranes and workshop structures), botón de parada de emergencia (manual emergency shutdown in case of danger), and anti-sway device (reducing the sway of lifting objects, especially for molten aluminum ladles, to avoid safety accidents).

4. Diseño personalizable

Combined with the different production processes and workshop layouts of various electrolytic aluminum enterprises, we provide fully customized services. According to customer needs, we can customize the lifting capacity, durar, altura de elevación, spreader type (anode spreader, cathode spreader, ladle spreader, etc.), modo de control (ground control, cab control, mando a distancia) and other parameters to perfectly match the actual production needs of customers.

5. Energy Saving & Mantenimiento fácil

Adopting energy-saving motor and frequency conversion control system, it can effectively reduce energy consumption, save operation costs for enterprises. The structural design is optimized, and key components are easy to disassemble and assemble. The lubrication system is centralized, which reduces the difficulty of daily maintenance and extends the service life of the equipment. At the same time, we provide detailed maintenance manuals and professional maintenance guidance to help customers reduce maintenance costs.

|

Nombre del parámetro

|

Rango de especificaciones

|

Observaciones

|

|---|---|---|

|

Capacidad de elevación nominal

|

5t – 200t

|

Personalizable

|

|

Durar

|

10m-35m

|

According to workshop size

|

|

Altura de elevación

|

6m-20m

|

Personalizable

|

|

Velocidad de elevación

|

0.5m/minuto – 10m/minuto

|

Frequency conversion adjustable

|

|

Running Speed (Carretilla)

|

2m/min – 20 m/min

|

Frequency conversion adjustable

|

|

Running Speed (Grúa)

|

5m/minuto – 30m/minuto

|

Frequency conversion adjustable

|

|

Clase trabajadora

|

A6 – A8

|

Adapt to continuous heavy load

|

|

Temperatura ambiente

|

-20℃ – 600℃

|

High-temperature resistant design

|

|

Modo de control

|

Ground control / Cab control / Mando a distancia

|

Optional or combined

|

Electrolytic Aluminum Overhead Crane

The electrolytic aluminum overhead crane is widely used in all links of the electrolytic aluminum production line, mainly including:

It is suitable for large and medium-sized electrolytic aluminum enterprises, and can adapt to different production scales and process requirements, providing all-round lifting support for the electrolytic aluminum industry.

Nos adherimos al principio de “calidad primero, safety first”, and all electrolytic aluminum overhead cranes are produced in strict accordance with international and national standards, including GB/T 3811-2008 (Crane Design Standards), GB 6067-2010 (Safety Standards for Cranes), e iso 9001 quality management system certification. All components are selected from well-known brands at home and abroad, and undergo strict inspection and testing before leaving the factory (including load test, high-temperature test, corrosion test, safety performance test, etc.) to ensure that each crane meets the quality and safety requirements.

To ensure the long-term stable operation of the equipment, we provide a full set of professional after-sales services:

If you are interested in our electrolytic aluminum overhead crane, or need to customize the equipment according to your actual production needs, no dude en contactarnos. Our professional team will provide you with detailed product consultation, technical solutions and quotation services.

Correo electrónico: aiden@craneweihua.com

We look forward to cooperating with you to contribute to the development of the electrolytic aluminum industry!

Valoramos sus comentarios! Complete el formulario a continuación para que podamos adaptar nuestros servicios a sus necesidades específicas..

Nuestro 80 El puente grúa de toneladas es un dispositivo de elevación tipo puente instalado en la parte superior ……

Descubre más →

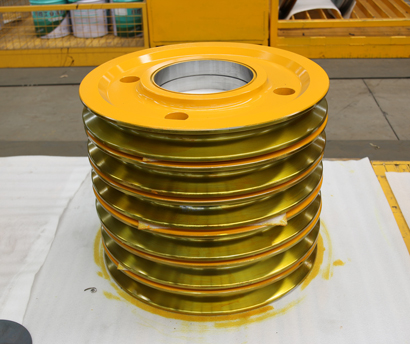

Descripción general del producto La polea del cable de la grúa es un componente crítico en la máquina de elevación……

Descubre más →

Introducción Cuando su operación exige confiabilidad, elevación eficiente de cargas de 8 toneladas, oh……

Descubre más →

Haga clic en el botón para obtener información del producto y cotizaciones en WhatsApp.

Obtener una cotización

Últimos comentarios