Un EOT de doble viga (Viaje aéreo eléctrico) crane is a robust, overhead lifting system designed for heavy-duty material handling in industrial environments.

Un EOT de doble viga (Viaje aéreo eléctrico) crane is a robust, overhead lifting system designed for heavy-duty material handling in industrial environments. A diferencia de single girder EOT crane, it features two parallel main girders spanning the workspace, supported by end carriages that travel along elevated runways. This structure enables it to handle significantly higher loads—typically ranging from 10 toneladas de 500 tons or more—making it ideal for demanding lifting tasks where precision, estabilidad, and durability are critical.

Powered by an electric motor, the double girder EOT crane operates via a hoist (mounted on a trolley) that moves along the girders, combined with runway travel for full coverage of the workspace. It is widely recognized as a reliable solution for streamlining operations in factories, almacenes, e industrias pesadas.

Double girder EOT cranes stand out for their advanced design and performance, offering the following advantages:

|

Parámetro

|

Range/Details

|

|

Capacidad de carga nominal

|

10t–500t+ (customizable for ultra-heavy loads)

|

|

Longitud del tramo

|

10m–35m (longer spans available with structural reinforcement)

|

|

Altura de elevación

|

6m–30m (adjustable based on workspace height)

|

|

Clase trabajadora

|

A5–A8 (Estándar ISO; A8 for continuous heavy-duty operations)

|

|

Velocidad de elevación

|

0.5m/min–10m/min (variable frequency control for smooth speed adjustment)

|

|

Velocidad de desplazamiento del carro

|

10m/min–40m/min

|

|

Velocidad de desplazamiento de la grúa

|

20m/min–60m/min

|

|

Fuente de alimentación

|

380V/50Hz (customizable for 220V/60Hz or other voltages)

|

|

Modo de control

|

Control colgante, control remoto inalámbrico, o control de cabina

|

|

Características de seguridad

|

Protección contra sobrecarga, interruptores de límite, parada de emergencia, anti-collision devices

|

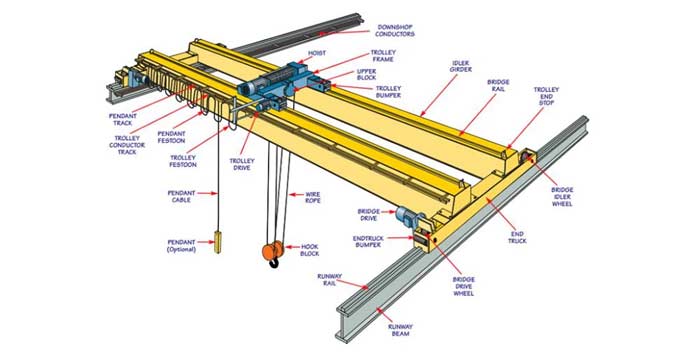

A double girder EOT crane consists of several key components working together to ensure reliable lifting:

Two parallel box-type or I-beam steel girders forming the primary load-bearing structure, spanning the workspace.

Located at both ends of the main girders, equipped with wheels that travel along the runway rails, enabling the crane to move horizontally.

The hoist (electric winch with hook, imán, or grab) is mounted on a trolley, which travels along the main girders via rails, allowing vertical lifting and horizontal movement along the span.

Elevated rails (installed on columns or walls) that guide the crane’s end carriages, defining the crane’s travel range.

Includes motors (izar, carretilla, crane travel), paneles de control, cables, y dispositivos de seguridad (overload sensors, interruptores de límite) to manage power and operations.

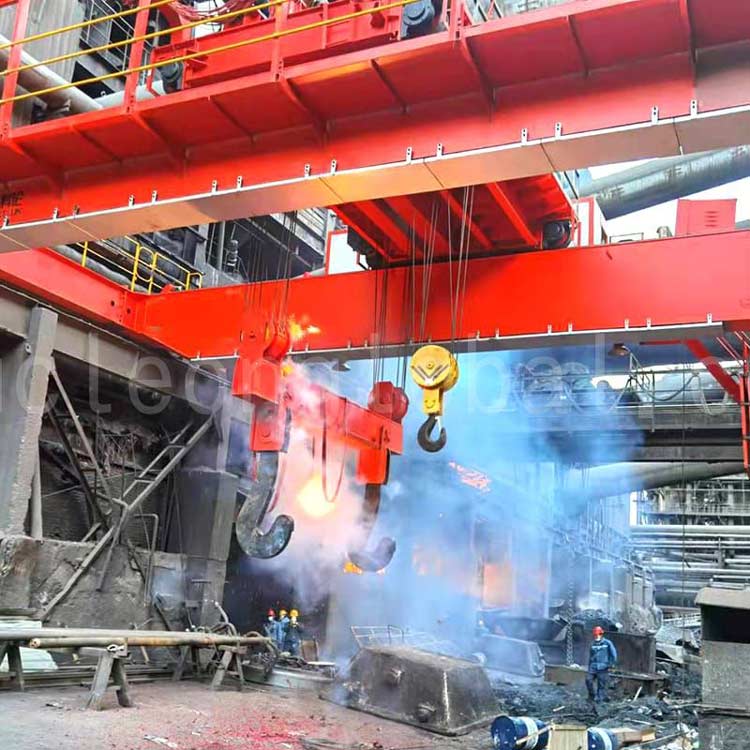

Double girder EOT cranes are indispensable in industries requiring heavy lifting and precise material handling:

Q1: What’s the difference between a double girder and single girder EOT crane?

A: Double girder cranes have two main girders, offering higher load capacity (10t+) y estabilidad, suitable for heavy-duty use. Single girder cranes have one girder, ideal for lighter loads (up to 20t) and smaller workspaces.

Q2: How often should a double girder EOT crane be maintained?

A: Routine inspections (daily checks for wear, monthly lubrication) and annual professional maintenance are recommended to ensure safety and extend service life.

Q3: Can double girder EOT cranes be customized for special environments?

A: Sí. Options include explosion-proof designs (for hazardous areas), corrosion-resistant coatings (for chemical plants), and high-temperature resistance (for foundries).

Q4: What safety standards do double girder EOT cranes comply with?

A: They adhere to international standards such as ISO, Femenado, DE, y OSHA, with built-in safety features like overload protection and emergency stops.

Q5: How long does it take to install a double girder EOT crane?

A: Installation time varies by size and complexity—typically 2–4 weeks for standard models, with longer timelines for custom or large-span systems.

Whether you need to lift heavy machinery in a factory or handle bulk materials in a port, our double girder EOT cranes deliver the strength, precisión, and reliability to optimize your operations. Contact us for a custom solution tailored to your needs.

Compartir con PDF: Descargar

Valoramos sus comentarios! Complete el formulario a continuación para que podamos adaptar nuestros servicios a sus necesidades específicas..

El 7 La grúa puente de toneladas es un equipo de manipulación de materiales versátil e indispensable ……

Descubre más →

The double girder overhead crane with electromagnet is a high-efficiency, heavy-duty li……

Descubre más →

Descripción general del producto El carro puente grúa es un componente central de los puentes grúa, de……

Descubre más →

Haga clic en el botón para obtener información del producto y cotizaciones en WhatsApp.

Obtener una cotización

Últimos comentarios