Cuando se trata de eficiencia, seguro, y manipulación duradera de materiales en talleres, fábricas, or warehouses, a 6 tons overhead crane stands out as a versatile workhorse. Designed to handle medium-duty lifting tasks with precision, this crane is engineered to streamline operations, reducir el trabajo manual, and enhance productivity across a range of industries. Whether you’re moving machinery, materias primas, or finished goods, nuestro 6 ton overhead crane delivers consistent performance you can trust.

What Is a 6 Toneladas Puente Grúa?

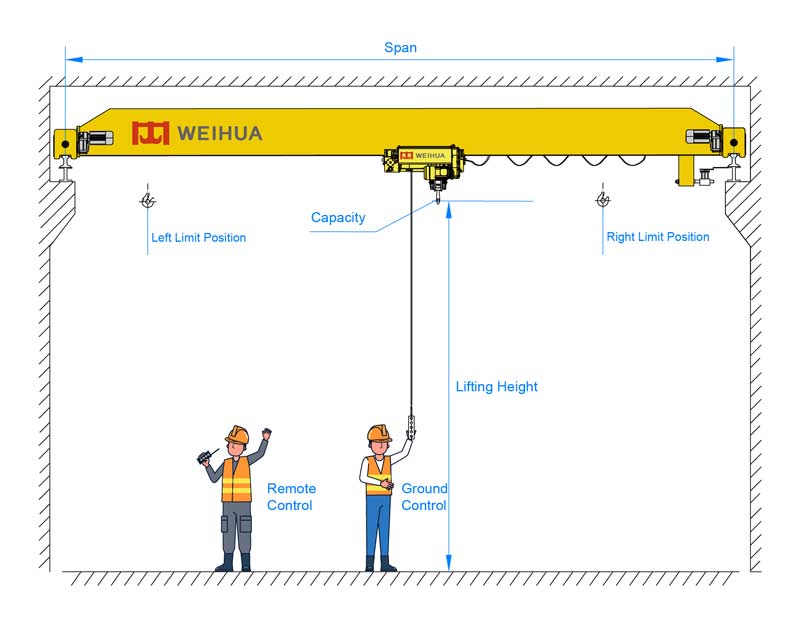

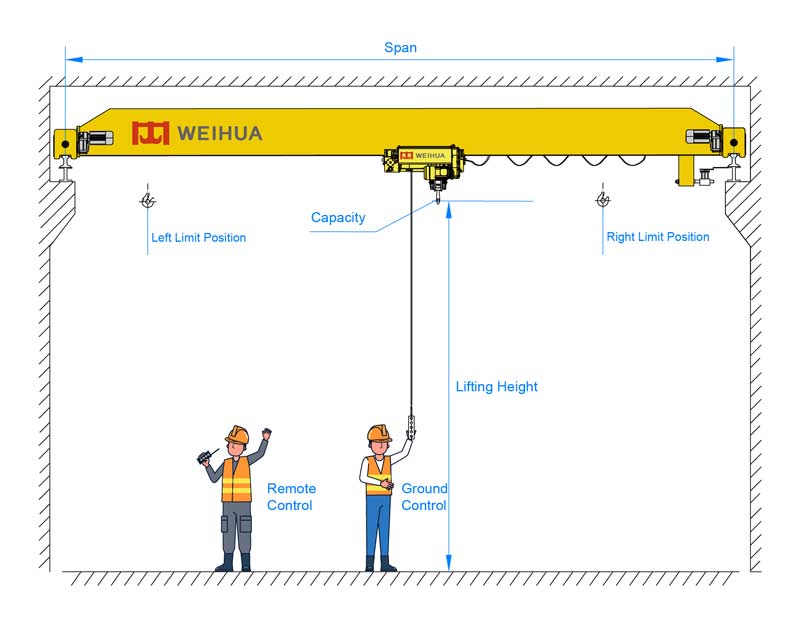

A 6 tons overhead crane is a type of material handling equipment designed to lift and transport loads up to 6 montones (12,000 lbs) within a fixed workspace. Mounted on a runway system that runs along the ceiling or elevated beams, it operates horizontally (along the runway) and vertically (via a hoist), allowing for 360° coverage of the working area. This design eliminates floor obstruction, maximizing usable space—critical for busy industrial environments.

Características clave de nuestro 6 Toneladas Puente Grúa

Nuestro 6 tons overhead crane is built with industry-leading standards to ensure reliability, seguridad, y rendimiento a largo plazo. Esto es lo que lo distingue:

- 1. High-Strength Construction: Crafted from premium grade steel, the crane’s bridge, end trucks, and hoist are engineered to withstand heavy loads and frequent use without deformation. This ensures a longer service life, even in harsh industrial conditions.

- 2. Efficient Hoist System: Equipped with a high-performance polipasto electrico, the crane offers smooth lifting and lowering operations with precise speed control (opciones de velocidad variable disponibles). The hoist is designed for low noise and minimal energy consumption, reducing operational costs.

- 3. Funciones de seguridad avanzadas: La seguridad no es negociable. Nuestro 6 tons overhead crane includes overload protection (prevents lifting beyond 6 montones), interruptores de límite (stops hoist at upper/lower limits), botones de parada de emergencia, y dispositivos anticolisión (for multi-crane setups). All components meet international safety standards (ISO, Ceñudo).

- 4. Fácil instalación & Mantenimiento: Designed for hassle-free setup, the crane’s modular components simplify installation, even in existing facilities. Maintenance is straightforward, with accessible parts and clear service guidelines to minimize downtime.

- 5. Opciones personalizables: We understand every workspace is unique. Choose from puente grúa monorraíl o grúa puente de dos vigas diseños, varying span lengths (8metros a 30 metros), and additional features like remote control (wireless or pendant), dust-proof enclosures, or corrosion-resistant coatings for outdoor use.

Especificaciones técnicas

|

Parámetro

|

Detalles

|

|

Capacidad de elevación nominal

|

6 montones (6,000 kg)

|

|

Tipo de grúa

|

Single-girder or double-girder available

|

|

Longitud del tramo

|

8m-30m (personalizable)

|

|

Altura de elevación

|

6m-20m (ajustable)

|

|

Velocidad de elevación

|

0.8 - 8 m/mi (variable options)

|

|

Velocidad de viaje (Puente)

|

10 - 30 m/mi

|

|

Velocidad de viaje (Carretilla)

|

5 - 15 m/mi

|

|

Fuente de alimentación

|

380V/3PH/50Hz (customizable for regions)

|

|

Clase trabajadora

|

A5 – A6 (suitable for frequent use)

|

6 Toneladas Puente Grúa: Composition & Key Lifting System

Basic Composition of 6 Toneladas Puente Grúa

A standard 6 tons overhead crane consists of four core components, working together to achieve stable and efficient material handling:

1. viga principal

The primary load-bearing structure, made of high-strength welded steel beams. It connects the end beams and supports the lifting trolley, ensuring even load distribution during operation.

2. End Beams

Installed at both ends of the main girder, they house the bridge travel mechanism. End beams are designed to fit the runway rails, enabling the crane to move horizontally along the workshop ceiling.

3. Travel Mechanism

Composed of motors, reductores, and wheels. The bridge travel mechanism drives the entire crane along the runway, while the trolley travel mechanism moves the hoist horizontally across the main girder.

4. Lifting System

6 polipasto electrico toneladas

The core part responsible for vertical load movement—centered on the 6 polipasto electrico toneladas, which is the key to realizing precise lifting and lowering.

Focus: 6 Polipasto eléctrico de toneladas (Lifting System Core)

El 6

tons electric hoist is the “power heart” of the puente grúa,

engineered for reliable medium-duty lifting.

Its design integrates advanced technology to balance performance, seguridad, y durabilidad.

Core Components of 6 Polipasto eléctrico de toneladas

- 1. High-Efficiency Motor: Equipped with a 3-phase asynchronous motor with class F insulation. It delivers strong torque for smooth starting and stable operation, with energy efficiency up to IE3 standard, reducing power consumption by 15-20% compared to conventional motors.

- 2. Hardened Gear Reducer: Adopts helical gear transmission for low noise (≤75dB) and high transmission efficiency (≥95%). Gears are carburized and quenched to HRC58-62 hardness, ensuring long service life even under frequent load changes.

- 3. Heavy-Duty Drum & Wire Rope: The drum is made of seamless steel pipe with a grooved surface to prevent rope slipping. The wire rope uses 6×37+FC high-strength steel, with a breaking force ≥120kN, ensuring safe lifting of 6-ton loads without deformation.

- 4. Dual-Brake System: Combines a mechanical disc brake and an electromagnetic brake. The electromagnetic brake acts as the main brake for instant stopping, while the disc brake serves as a backup, eliminating the risk of load falling due to single brake failure.

Performance Advantages of the Lifting System

- 1. Precise Speed Control: Supports variable lifting speeds (0.8-8 m/mi) and trolley speeds (5-15 m/mi). Slow speed mode (0.8-2 m/mi) is ideal for positioning fragile or heavy loads, reducing collision risks.

- 2. Low Maintenance Design: Sealed bearing units and lubrication-free components minimize maintenance frequency. The hoist’s detachable cover allows easy access to internal parts for inspection or repair, cutting downtime by 30%.

- 3. Wide Adaptability: Available in standard, a prueba de polvo, and corrosion-resistant versions. The dust-proof hoist is suitable for workshops with metal chips or powder, while the corrosion-resistant one works in humid or outdoor environments (P.EJ., coastal factories).

Safety Design of 6 Polipasto eléctrico de toneladas

In line with ISO and CE safety standards, the electric hoist is equipped with multiple protection measures:

- 1. Overload limiter: Automatically cuts off the lifting circuit when the load exceeds 110% de la capacidad nominal (6.6 montones).

- 2. Upper/lower limit switches: Stop the hoist when the hook reaches the maximum or minimum lifting height, preventing overwinding or overlowering.

- 3. Emergency stop function: Integrates with the crane’s main emergency button, enabling immediate shutdown of the hoist in case of emergencies.

Aplicaciones: Where a 6 Tons Overhead Crane Excels

El 6 tons overhead crane is ideal for medium-duty lifting needs across diverse industries:

- 1. Instalaciones de fabricación: Move machine parts, moldes, or assemblies on production lines.

- 2. Almacenes & Logística: Load/unload pallets, stack goods, or transfer inventory efficiently.

- 3. Talleres de Automoción: Lift engines, chassis, or heavy components during assembly or repair.

- 4. Metalworking & Fabrication: Handle steel plates, tubería, or welded structures safely.

- 5. Construction Yards: Transport building materials in enclosed or semi-enclosed work zones.

- 6. Alimento & Industria de bebidas: Move bulk ingredients or packaged goods in hygienic settings (with food-grade modifications).

¿Por qué elegir nuestro? 6 Toneladas Puente Grúa?

- 1. Calidad probada: Respaldado por 20+ años de experiencia en la fabricación de grúas, our products undergo rigorous testing to ensure durability and performance.

- 2. Cumplimiento: All cranes meet international standards (ISO 9001, Ceñudo, Femenado), ensuring compatibility with global industrial regulations.

- 3. Soluciones a medida: Our team works with you to design a crane that fits your workspace, requisitos de carga, y presupuesto.

- 4. Apoyo integral: From pre-sales consultation to installation, capacitación, y servicio postventa, we’re with you every step of the way.

Ready to enhance your material handling efficiency with a reliable 6 tonelada de grúa por encima? Contact us today for a free quote, technical advice, or to discuss your custom requirements. Let’s build a solution that lifts your operations to the next level.

Compartir con PDF: Descargar

Últimos comentarios