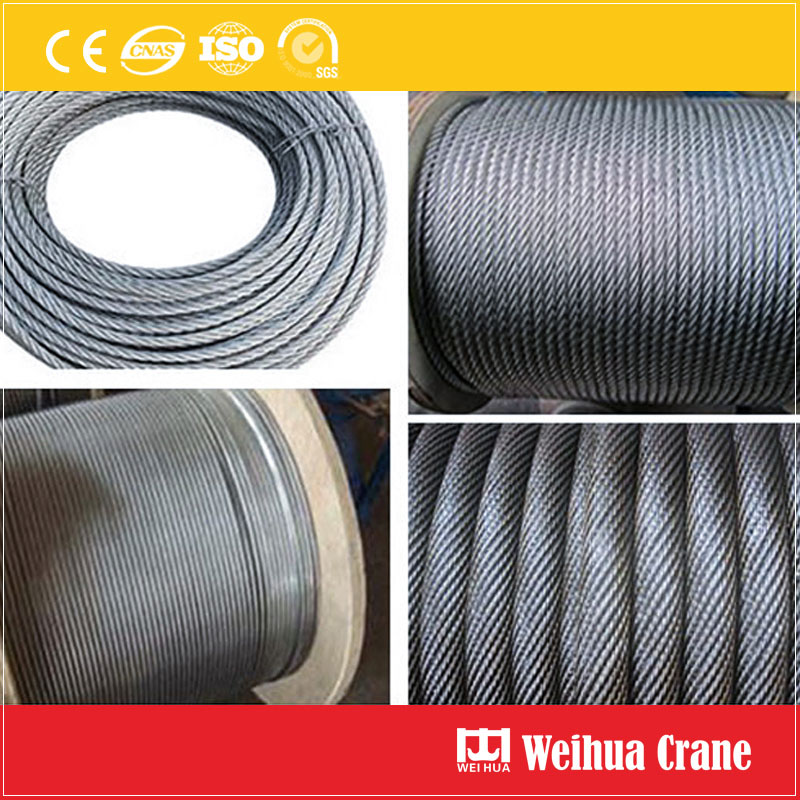

El cable metálico de la grúa es un componente clave utilizado en la elevación., equipos de elevación y tracción. Está hecho de múltiples hilos de alambre de acero trenzado y tiene las características de alta resistencia., resistencia al desgaste y resistencia a la corrosión. Es muy utilizado en puentes grúa., grúas de pórtico, grúas para contenedores, polipastos electricos, etc..

En el mundo exigente del manejo de materiales, construcción, y levantamiento pesado, Cada componente debe funcionar con confiabilidad inquebrantable.. En el centro de estas operaciones críticas se encuentra Crane Wire Rope, un producto diseñado no solo para levantar, pero para aguantar, asegurar, y para empoderar.

Nuestros cables para grúas son la culminación de la metalurgia avanzada., fabricación de precisión, y pruebas rigurosas. Están diseñados para ser los más fuertes., más duradero, y el eslabón más seguro de su sistema de elevación, garantizando el máximo rendimiento en los entornos más desafiantes.

1. Fuerza sin concesiones & Durabilidad:

Construido con acero con alto contenido de carbono con varios grados. (P.EJ., IPS, PEI, EEIP), Nuestras cuerdas ofrecen una resistencia a la tracción excepcional.. Esto significa un mayor factor de seguridad., mayor resistencia a la rotura, y la capacidad de manejar su carga de trabajo máxima con confianza.

2. Resistencia a la fatiga mejorada:

La flexión constante sobre poleas y tambores es la causa principal de fallas en los cables metálicos.. Nuestras cuerdas están diseñadas con una construcción de núcleo óptima y un patrón de hebras preciso para soportar millones de ciclos de flexión., ampliando significativamente la vida útil y reduciendo el tiempo de inactividad.

3. Resistencia superior a la abrasión:

Ofrecemos una gama de tratamientos superficiales., incluyendo brillante (Sin recubrimiento), Galvanizado, y acero inoxidable, para combatir el desgaste y la corrosión. Para las condiciones más duras, Nuestro cable de acero impregnado de plástico (PVC o nailon) El revestimiento proporciona una capa adicional de protección contra la abrasión., humedad, y exposición química.

4. Excepcional resistencia al aplastamiento:

Un núcleo robusto, ya sea un núcleo de cable independiente (IWRC) o núcleo de fibra (FC)—es vital. Nuestra construcción IWRC proporciona un soporte superior contra cargas elevadas y fuerzas de aplastamiento en los tambores., mientras que nuestro FC ofrece una excelente flexibilidad y amortiguación..

5. Personalizado para su aplicación:

No hay dos ascensores iguales. Ofrecemos una variedad de construcciones. (P.EJ., 6×19, 6×36, 6x25FW, 8×19) para satisfacer sus necesidades específicas:

6Clase ×19: Un caballo de batalla versátil para servicio general de grúas, izar, y arrastrando.

6Clase ×36: Ofrece más cables para una mayor flexibilidad., ideal para aplicaciones que requieren colas frecuentes.

Resistente a la rotación: Construcción multicapa diseñada para evitar que gire bajo carga., esencial para una sola línea, ascensores suspendidos.

| Grados | IPS (1770 N/mm²), PEI (1960 N/mm²), EEIP (2160 N/mm²) |

| Núcleos | Núcleo de cable independiente (IWRC), Núcleo de fibra (FC), Núcleo sintético (CAROLINA DEL SUR) |

| Construcciones | 6x19S, 6x25FW, 6x36WS, 6x41WS, 8x19S, y tipos resistentes a la rotación. |

| Recubrimientos | Brillante (sin recubrir), Galvanizado (Recubierto de zinc), Recubierto de PVC/nylon, Acero inoxidable. |

| Lubricación | Impregnado con un lubricante de alto rendimiento durante la fabricación para reducir la fricción interna y prevenir la corrosión.. |

Nuestros cables para grúas gozan de confianza en multitud de sectores.:

El principio general de las normas de seguridad como OSHA y ASME B30.2 es: Un cable metálico debe retirarse del servicio cuando haya evidencia de distorsión., desgaste excesivo, corrosión, o daño que podría resultar en una pérdida mensurable de fuerza o integridad funcional.

En la práctica, esto está determinado por regulares, inspecciones documentadas. Hay dos categorías principales de inspección.:

Elegir el cable metálico adecuado es fundamental. Nuestro equipo técnico está listo para ayudarle a seleccionar el cable perfecto para la capacidad de carga de su grúa., ciclo de trabajo, y condiciones ambientales.

Contáctenos hoy para una consulta y cotización..

Valoramos sus comentarios! Complete el formulario a continuación para que podamos adaptar nuestros servicios a sus necesidades específicas..

30 Toneladas grúa pórtico (General Type) 30 Toneladas grúa pórtico (General Type) Introduction T……

Descubre más →

Introducción a Weihua 32 Toneladas Puente Grúa weihua 32 toneladas de puente grúa es un alto-……

Descubre más →

Descripción general del producto Nuestra grúa pórtico portátil es un diseño de equipo de elevación revolucionario...

Descubre más →

Haga clic en el botón para obtener información del producto y cotizaciones en WhatsApp.

Obtener una cotización

Últimos comentarios