En el bullicioso mundo de la fabricación, almacenes, sitios de construcción, y puertos, Los puentes grúa son caballos de batalla indispensables. Estas máquinas de servicio pesado agilizan el manejo de materiales, levantar cargas masivas, y mejorar la eficiencia operativa. ¿Pero alguna vez te has preguntado qué hace que estas grúas sean tan confiables y versátiles?? La respuesta está en sus componentes bien diseñados., cada uno desempeña un papel único y crítico. en este blog, romperemos la clave puente grúa Componentes y sus funciones esenciales., ayudándole a obtener una comprensión más profunda de cómo operan estos gigantes industriales.

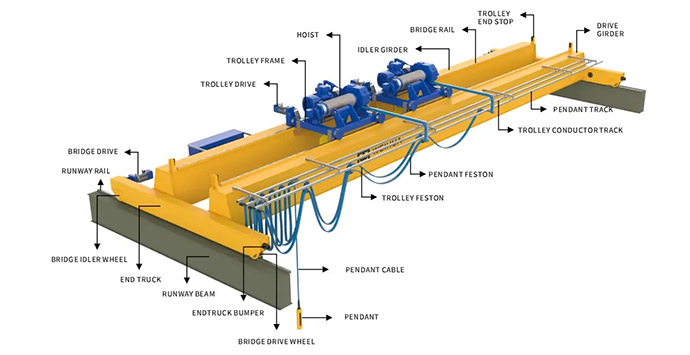

La viga del puente, a menudo denominada viga principal, es la columna vertebral de una grúa puente. Es la estructura horizontal que se extiende a lo ancho del espacio de trabajo. (P.EJ., entre dos pistas de grúa) y soporta el peso de la carga, carretilla, y otros componentes.

Funciones:

Las vigas de los puentes suelen estar hechas de acero de alta resistencia para soportar cargas extremas.. Los diseños comunes incluyen los de una sola viga. (para cargas más ligeras) y de dos vigas (para mas pesado, aplicaciones más exigentes) configuraciones.

Los testeros están montados en ambos extremos de la viga del puente.. Ellos albergan el ruedas de puente grúa, ejes, y mecanismos de accionamiento que permiten que toda la grúa se mueva a lo largo de los carriles de rodadura instalados en las paredes o columnas del edificio..

Funciones:

El diseño de las cabezas varía según la capacidad de la grúa y los requisitos de velocidad.. Algunas cabezas utilizan unidades motorizadas para el movimiento automatizado., mientras que otras pueden operarse manualmente para grúas de servicio más liviano.

El carro es una unidad móvil que se desplaza a lo largo de la parte superior o inferior de la viga del puente.. Lleva el mecanismo de elevación. (la parte que levanta la carga) y permite el movimiento lateral (de lado a lado) de la carga dentro del área de cobertura de la grúa.

Funciones:

Los carros se clasifican en diferentes tipos., como el de mayor rendimiento (viaja sobre la viga del puente) y subfuncionamiento (viaja debajo de la viga del puente), dependiendo del diseño y aplicación de la grúa.

El mecanismo de elevación es el corazón del puente grúa., Responsable de subir y bajar la carga.. Consta de varios subcomponentes., incluyendo un motor, caja de cambios, tambor de cable de grúa, cuerda de alambre o cadena, manos, y frenos.

Funciones:

La capacidad del mecanismo de elevación determina la carga máxima que la grúa puede levantar.. Por ejemplo, una grúa con un mecanismo de elevación de 10 toneladas puede levantar cargas de hasta 10 montones.

El gancho Es el componente que se une directamente a la carga.. Se suspende del mecanismo de elevación mediante cables o cadenas y viene en varios diseños para adaptarse a diferentes tipos de cargas..

Funciones:

Los ganchos de la grúa están hechos de acero aleado de alta resistencia para soportar cargas pesadas y se inspeccionan periódicamente para detectar desgaste., grietas, o deformación para garantizar la seguridad.

La cabina del operador es el centro de control del puente grúa., donde el operador se sienta para manipular los movimientos de la grúa. Para grúas más pequeñas o utilizadas en espacios reducidos, colgantes de control (controles de botón de mano) o a menudo se utilizan mandos a distancia por radio.

Funciones:

Los controles remotos por radio ofrecen mayor flexibilidad, Permitir que el operador permanezca en la posición óptima para monitorear la carga sin estar confinado a la cabina..

El sistema eléctrico alimenta y controla todos los componentes de la grúa., incluyendo el motor de elevación, motor del carro, motores de viaje, frenos, y sistemas de control. Consta de una fuente de alimentación., motores, inversores, controladores, cables, y dispositivos de seguridad.

Funciones:

Las grúas puente modernas suelen utilizar accionamientos de frecuencia variable. (VFD) en sus sistemas eléctricos para optimizar la eficiencia energética y mejorar el control sobre la velocidad de movimiento.

Aunque no siempre se considera parte de la propia grúa, Los carriles de rodadura son esenciales para el funcionamiento de la grúa.. Se instalan a lo largo del espacio de trabajo. (generalmente en las columnas o estructuras de soporte del edificio) y proporcionar una vía para que los cabezales de la grúa se desplacen.

Funciones:

Los rieles de la pista deben estar correctamente alineados y nivelados para evitar el desgaste excesivo de las ruedas de la grúa y garantizar una operación segura..

Q1: ¿Con qué frecuencia se deben inspeccionar los componentes del puente grúa??

A1: La frecuencia de inspección depende del componente y de la intensidad de uso.. Componentes críticos de carga (como vigas de puente, manos, y cables de alambre) El operador debe someterse a inspecciones visuales diarias antes de su uso.. Se recomiendan inspecciones exhaustivas realizadas por técnicos cualificados trimestralmente., y exámenes minuciosos anuales (incluyendo pruebas no destructivas para piezas de alto desgaste) son necesarios para garantizar el cumplimiento de las normas de seguridad. Para grúas utilizadas en entornos hostiles (P.EJ., temperatura alta, corrosión), Las inspecciones deberían ser más frecuentes..

Q2: ¿Cuáles son los principales signos de que es necesario sustituir un componente de la grúa??

A2: Las señales de advertencia clave incluyen grietas visibles, deformación, o desgaste excesivo en vigas y ganchos del puente; raedura, hebras rotas, o corrosión en cables metálicos; Ruidos anormales o vibraciones de los motores., cajas de cambios, o testeras; rendimiento de frenado inconsistente; y fallo de los dispositivos de seguridad (P.EJ., interruptores de límite, protectores de sobrecarga) para funcionar correctamente. Cualquier componente que muestre estos signos debe reemplazarse inmediatamente para evitar accidentes..

Q3: ¿Se pueden mezclar y combinar diferentes marcas de componentes de puentes grúa??

A3: No se recomienda mezclar ni combinar componentes de diferentes marcas a menos que lo apruebe explícitamente el fabricante de la grúa.. Los componentes de la grúa están diseñados para funcionar de forma sinérgica, y las piezas que no coinciden pueden no cumplir con los requisitos de carga originales., seguridad, o requisitos operativos. Esto puede conducir a un rendimiento reducido., mayor desgaste, y posibles riesgos de seguridad. Si un componente necesita reemplazo, Lo mejor es utilizar piezas originales del fabricante o equivalentes autorizados..

Q4: ¿Cómo afecta el entorno de trabajo a la vida útil de los componentes del puente grúa??

A4: Los entornos hostiles acortan significativamente la vida útil de los componentes. Las altas temperaturas pueden degradar los lubricantes y debilitar las estructuras metálicas.; ambientes húmedos o corrosivos (P.EJ., puerto, plantas químicas) Causa óxido y corrosión en componentes metálicos como ruedas de testeras y sistemas eléctricos.; Los ambientes polvorientos pueden obstruir motores y cajas de cambios., provocando sobrecalentamiento y fallos prematuros. Para mitigar estos efectos, Medidas de protección como revestimientos resistentes a la corrosión., cubiertas antipolvo, y se deben utilizar lubricantes de alta temperatura, y se debe mejorar el mantenimiento regular.

El rendimiento de un puente grúa depende de la perfecta colaboración de todos sus componentes. Desde la viga del puente (la columna vertebral) al mecanismo de elevación (el corazon) y la cabina del operador (el cerebro), Cada parte juega un papel vital para garantizar la seguridad., eficiente, y manipulación fiable de materiales. Comprender estos componentes y sus funciones no solo es útil para los operadores de grúas y los equipos de mantenimiento, sino también para los propietarios de empresas que buscan invertir u optimizar sus equipos de manipulación de materiales..

Ya sea que esté operando una pequeña grúa monorraíl en un taller o una gran grúa birraíl en un puerto, El mantenimiento adecuado de cada componente es clave para prolongar la vida útil de la grúa y garantizar la seguridad en el lugar de trabajo.. Inspecciones regulares, lubricación, y las reparaciones mantendrán su puente grúa funcionando sin problemas en los años venideros.

Tiene preguntas sobre los componentes del puente grúa o necesita asesoramiento para elegir la grúa adecuada para su aplicación.? No dudes en dejar un comentario a continuación.!

Valoramos sus comentarios! Complete el formulario a continuación para que podamos adaptar nuestros servicios a sus necesidades específicas..

Haga clic en el botón para obtener información del producto y cotizaciones en WhatsApp.

Obtener una cotización

Últimos comentarios