Comparación de grado de material de gancho de la grúa

2025-09-17

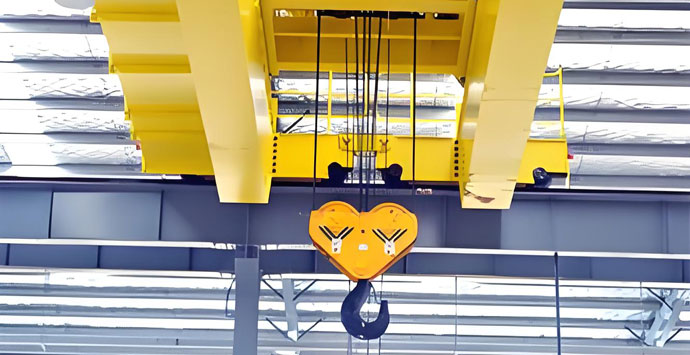

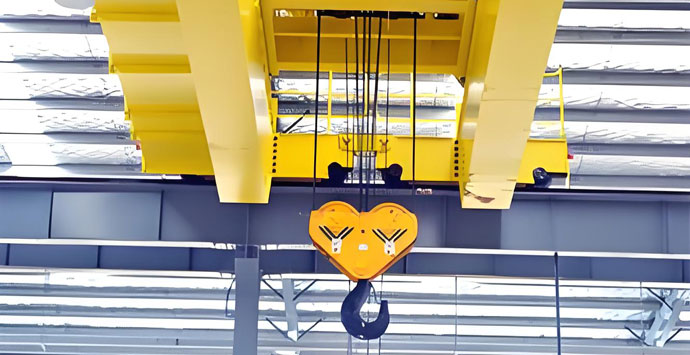

When it comes to heavy lifting, all eyes are on the crane—its impressive height, its powerful hoist, its graceful movement. But the true unsung hero, the critical point where all that power converges, is a relatively small component: el gancho. This humble piece of metal bears the entire weight of the load, and its failure is not an option.

The integrity of a crane hook is almost entirely dependent on the material from which it’s forged. Choosing the right grade isn’t just about strength; it’s about toughness, ductility, y resistencia a la fatiga. In this post, we’ll break down the common material grades used for crane hooks and help you understand what makes each one suitable for its specific role.

Why Material Choice is Critical

A crane hook is subjected to immense and complex stresses—primarily tension, but also bending and potential side-loading. The ideal material must possess a combination of:

- 1. High Yield Strength: To resist permanent deformation under load.

- 2. High Tensile Strength: To resist fracturing.

- 3. Buena ductilidad: To deform slightly (stretch) before breaking, providing a visual warning.

- 4. Excellent Toughness: To absorb energy and resist shock loading and impact.

- 5. Fatigue Resistance: To withstand repeated load cycles without developing cracks.

Now, let’s compare the most common material grades.

Acero carbono (P.EJ., A36 or Equivalent)

- 1. Overview: This is a general-purpose, low-carbon steel. It is malleable, relatively inexpensive, and easy to fabricate.

- 2. Typical Use: Light-duty applications. You might find hooks made from these grades on smaller workshop cranes, grúas de bandera, or for very low-capacity loads.

- 3. Pros: Cost-effective, good weldability.

- 4. Cons: Lower strength and toughness compared to alloy steels. Not suitable for heavy loads, dynamic lifting, or cold environments where it can become brittle.

- 5. Verdict: A basic choice for non-critical, low-capacity lifting.

High-Strength Low-Alloy Steel (HSLA) (P.EJ., ASTM A572 Grade 50)

- 1. Overview: This grade offers a significant step up from carbon steel. By adding small amounts of alloying elements like columbium-vanadium, it achieves higher yield and tensile strength while maintaining good formability.

- 2. Typical Use: Medium-duty crane hooks and other structural components. A very common and versatile material.

- 3. Pros: Excellent strength-to-weight ratio, better resistance to atmospheric corrosion than carbon steel, and good weldability.

- 4. Cons: While stronger, its toughness and fatigue resistance may still be outperformed by more specialized grades.

- 5. Verdict: The reliable workhorse for a wide range of general industrial lifting applications.

Acero aleado (P.EJ., ASTM A508 / A508 Gr.4N)

- 1. Overview: This is where we enter the realm of high-performance crane hooks. Alloy steels like A508 are quenched and tempered to achieve an exceptional combination of very high strength and superior toughness.

- 2. Typical Use: Heavy-duty and high-capacity hooks for overhead cranes, grúas torre, y grúas móviles. This is the industry standard for serious lifting.

- 3. Pros: Exceptional yield and tensile strength, outstanding impact toughness (even at low temperatures), and excellent fatigue life. It is designed to bend, not break.

- 4. Cons: More expensive than carbon or HSLA steels. Requires precise heat treatment during manufacturing.

- 5. Verdict: The premium choice for safety-critical, alta capacidad, and high-cycle applications.

Acero inoxidable (P.EJ., 316 o 410 Stainless)

- 1. Overview: The primary advantage of stainless steel is its exceptional corrosion resistance.

- 2. Typical Use: Specialized environments where moisture and chemicals are a constant threat. Think marine applications, plantas químicas, food and beverage processing, and pharmaceuticals.

- 3. Pros: Excellent corrosion resistance, hygienic properties (easy to clean).

- 4. Cons: Generally has lower strength than an equivalently sized alloy steel hook. Significantly more expensive. The fatigue strength can also be lower.

- 5. Verdict: Not chosen for its strength, but for its resistance to corrosive environments where a standard steel hook would quickly degrade and become unsafe.

Comparison Table at a Glance

| Grado del material |

Typical Use Case |

Key Properties |

Mejor para |

| Acero carbono (A36) |

Light-Duty |

Low cost, good weldability |

Non-critical, low-capacity lifts |

| HSLA Steel (A572 Gr. 50) |

Medium-Duty |

Good strength-to-weight ratio |

General industrial applications |

| Acero aleado (A508) |

Servicio pesado |

High strength & superior toughness |

Alta capacidad, safety-critical lifts |

| Acero inoxidable (316/410) |

Corrosive Environments |

Excellent corrosion resistance |

Marina, químico, food & beverage industries |

How to Choose: It’s Not Just About the Grade

While material grade is paramount, it’s only one part of the equation. The manufacturing process—specifically forging and heat treatment—is equally important.

- 1. Forja: Forged crane hooks are stronger than those that are cast or cut from plate. Forging aligns the metal’s grain structure to the shape of the hook, creating a part that is inherently stronger and more resistant to impact.

- 2. Tratamiento térmico (Temple & Templado): This process precisely controls the hardness, fortaleza, y, lo más importante, the toughness of the final product. A properly heat-treated hook has the perfect balance of being strong enough to hold the load yet tough enough to deform under extreme overload.

Always look for hooks that are certified to relevant standards (como ASME B30.10), which govern the material, diseño, fabricación, and testing processes.

There is no one-size-fits-all answer. The “best” crane hook material is the one that is fit-for-purpose:

- 1. For standard factory lifting, an A572 or A508 hook is typical.

- 2. For the most demanding, heavy-cycle, and highest-capacity lifts, alloy steel like A508 is the unequivocal choice for maximum safety.

- 3. Never compromise with a carbon steel hook for a demanding application, and only choose stainless steel when the environment demands it.

Always consult the manufacturer’s specifications and ensure your hook has the proper certifications for your application. Recordar, the hook is the final, critical link in your lifting chain—investing in the right material is investing in safety.

Últimos comentarios