A Wire Rope Guide (WRG) Das System ist ein fortschrittliches Sicherheits- und Steuergerät für Turmdrehkrane und andere Hebezeuge. Seine Hauptfunktion besteht darin, das Hubseil zu steuern, verhindert, dass es unkontrolliert schwingt, "Vogelkäfig" (untwisting), oder die Struktur des Krans beeinträchtigen, insbesondere bei Hochgeschwindigkeits- oder Langstreckeneinsätzen.

Das Seilführungssystem ist eine hochmoderne Pendel- und Führungslösung für moderne Laufkrane. Es ist ein unverzichtbares Zubehör, das die präzise Positionierung und Stabilität des gewährleistet Kranhaken und Last, indem das Drahtseil physisch entlang einer definierten Bahn geführt wird. By replacing traditional, weniger effektive Methoden wie Slogans oder komplexe sensorbasierte Systeme, Der Seilführer erhöht die Sicherheit, verbessert die betriebliche Effizienz, und reduziert Lastschwankungen erheblich, Dies führt zu einer schnelleren und genaueren Lastplatzierung.

Dieses System ist besonders wichtig bei Anwendungen, bei denen es auf Präzision ankommt, beispielsweise in überfüllten Produktionshallen, automatisierte Lagersysteme, oder beim Umgang mit empfindlichen und hochwertigen Gütern.

1. Superior Load Stability & Anti-Sway

Reduziert die durch Kranbewegungen verursachten Lastschwankungen erheblich, cross-traveling, oder Umweltfaktoren wie Wind. Dies ermöglicht eine punktgenaue Platzierung der Lasten, even at high speeds.

2. Erhöhte Betriebssicherheit

Minimiert die Unfallgefahr durch schwingende Lasten, protecting personnel, Infrastruktur, und die Ladung selbst. Schafft eine sicherere und vorhersehbarere Arbeitsumgebung.

3. Erhöhte Produktivität & Effizienz

Bediener können den Kran mit höheren Geschwindigkeiten betreiben, ohne dass die Präzision darunter leidet, Reduzierung der Zykluszeiten. Es wird weniger Zeit mit Manövrieren und Warten auf die Stabilisierung der Ladung aufgewendet.

4. Reduzierter Seilverschleiß

Die Führungsscheiben sind so konstruiert, dass der abrasive Kontakt mit dem Drahtseil minimiert wird, verhindert vorzeitigen Verschleiß, „Vogelkäfig,” und andere Formen der Seilschädigung. Dies verlängert die Lebensdauer Ihrer Drahtseile.

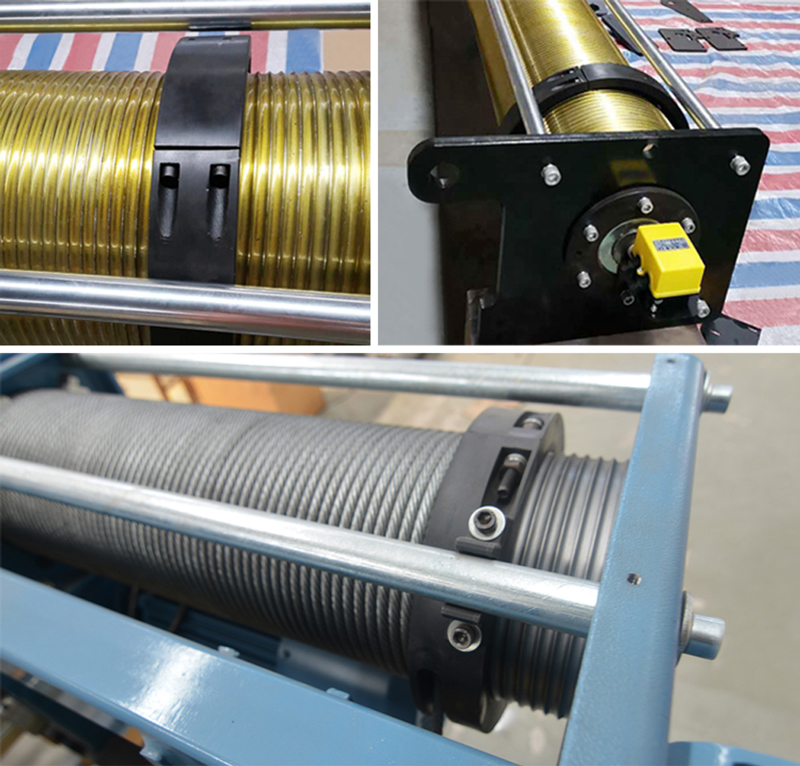

5. Einfaches und robustes Design

Aus hochfestem Material gefertigt, langlebige Materialien (Z.B., gehärteter Stahl, Polymerverbundwerkstoffe) für lange Lebensdauer bei minimalem Wartungsaufwand. Das System ist mechanisch einfach und äußerst zuverlässig.

6. Einfache Installation und Integration

Entwickelt für die einfache Nachrüstung bestehender Systeme Brückenkräne oder als integrierte Komponente für neue Krane geliefert. Kompatibel mit den meisten Standardkran- und Hebezeugmodellen.

7. Verbesserte Präzision in automatisierten Systemen

Unverzichtbar für automatisierte/bedienerlose Kransysteme (AGCs) where consistent, wiederholbar, und eine genaue Lastpositionierung ist nicht verhandelbar.

Notiz: Die folgende Tabelle enthält allgemeine Spezifikationen. Die genauen Parameter können je nach Krankapazität und spezifischem Modell variieren.

| Parameter | Spezifikation | Notizen |

| Kompatible Krankapazität | 1 Tonne zu 500+ Tonnen | Für höhere Kapazitäten sind kundenspezifische Designs verfügbar. |

| Seildurchmesserbereich | 6 mm zu 22 mm | Passend für die meisten Standard-Drahtseile. |

| Guide Sheave Material | Nylon, Polyamid, oder Gussstahl | Die Auswahl hängt von der Anwendung und dem Seiltyp ab. |

| Rahmenmaterial | High-Tensile Steel Plate | Bietet strukturelle Integrität und Haltbarkeit. |

| Mounting Options | Oben auf Hebeblock montiert / Side-mounted on trolley | Flexible Installation basierend auf der Krankonfiguration. |

| Betriebstemperatur | -20° C bis +80 ° C. | Geeignet für die meisten industriellen Umgebungen. |

| Schutzbewertung | IP65 / IP66 (Optional) | Schutz gegen Staub und Strahlwasser für raue Bedingungen. |

Das Seilführungssystem ist vielseitig und kann an einer Vielzahl von Hebegeräten eingesetzt werden, einschließlich:

Verbessern Sie die Leistung Ihres Krans, Sicherheit, und Effizienz. Unser Ingenieurteam hilft Ihnen gerne bei der Auswahl und Integration des perfekten Seilführungssystems für Ihre spezifischen Anforderungen.

Wir schätzen Ihr Feedback! Bitte füllen Sie das folgende Formular aus, damit wir unsere Dienste auf Ihre spezifischen Anforderungen anpassen können.

Der 50 tons overhead crane is a heavy-duty lifting equipment designed for handling larg……

Entdecken Sie mehr →

For industrial material handling requirements requiring a reliable 2 Tonnen-Portalkran, ……

Entdecken Sie mehr →

20 Tonnen-Einzelträger vs. Doppelträger-Brückenkrane Der Hauptunterschied im 20-Tonnen-O……

Entdecken Sie mehr →

Klicken Sie auf die Schaltfläche, um Produktinformationen und Angebote auf WhatsApp zu erhalten.

Holen Sie sich Zitat

Neueste Kommentare