Weihua forklift crane hook adopts a quick connector system, which is suitable for mainstream brand forklifts and can be installed quickly. The hook body adopts alloy steel one-piece forging technology to improve the tensile strength of the hook. Meet various lifting needs under different working conditions.

In der Lagerlogistik, Gerätewartung oder temporäre Hebe-Szenarien, traditional cranes are often costly and lack maneuverability. Weihua’s innovatively designed forklift crane hook (special Hebekranhaken for forklifts) allows standard forklifts to be upgraded to mobile mini-cranes in 3 Sekunden! Through the perfect combination of high-strength hook components and intelligent safety locks, we provide you with a low-cost, highly flexible heavy object lifting solution.

Patented quick connector system:

Suitable for mainstream brand forklifts.

No tools required, one person can complete hook/fork switching in 3 Sekunden.

Modification-free design: directly utilize the existing hydraulic attachment interface of the forklift to retain the original vehicle load capacity.

One-piece forged hook body:

Material: Aisi 4140 Legierungsstahl (tensile strength ≥1200 MPa).

Safety factor ≥5:1, far exceeding ISO 10535 Standard.

Triple insurance mechanism: Mechanical self-locking tongue (anti-decoupling); Dual redundant safety pins (to prevent accidental unlocking); Overload alarm module (optional, 110% load whistle).

CE-Zertifizierung + ISO 10535 Testbericht: third-party certificate provided with goods.

Low headroom compact type: the distance from hook tip to fork frame is ≤200mm (standard fork position), maximizing the use of lifting height.

360° rotating bearing: the load direction can be manually adjusted during hoisting to avoid rope entanglement.

Modular expansion interface: can be installed:

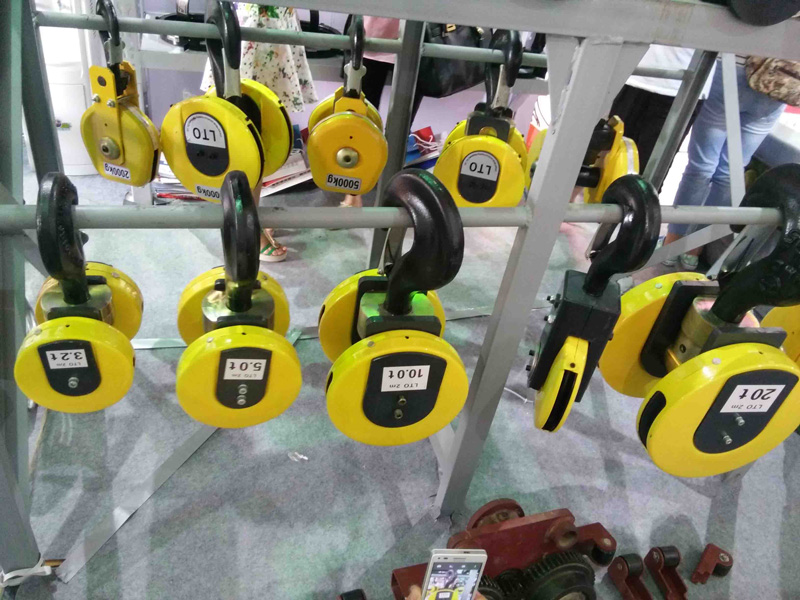

Electronic scale (accuracy ±0.5%).

Double hook balancing beam (asymmetrical loading).

Magnetic chuck (steel plate lifting).

| Modell | Safe working load | Applicable forklift tonnage | Hakenbreite | Featured scenes |

| WH-FH1 | 1 Tonne | 1.5~3t | 60mm | Warehouse equipment maintenance |

| WH-FH3 | 3 Tonne | 3~5t | 80mm | Mold/mechanical component lifting |

| WH-FH5 | 5 Tonne | 5~8t | 100mm | Small container unpacking |

| WH-FH10 | 10 Tonne | 10t+ | 150mm | Factory equipment installation |

Surface strengthening process:

Shot peening (anti-fatigue) + Heißtip-Galvanisierung (anti-corrosion).

Optional stainless steel version (food/chemical industry).

Self-lubricating bearings: 10,000 hours maintenance-free.

Container cargo unpacking operation

Pain point: Large equipment cannot be taken out with forks, and the cost of hiring a crane is $500+/hour.

Weihua plan:

WH-FH5 hook + lifting strap.

The forklift drives directly into the container and lifts out the heavy objects.

Cost comparison: save 80% on rental fees.

Quick replacement of production line molds

Pain point: Changing the mold of the injection molding machine requires two people to operate the crane, which takes 30 Minuten.

Weihua plan:

WH-FH3 hook + mold special lifting beam.

One person completes air transfer of mold in 5 Minuten.

Effizienzsteigerung: mold change time is reduced by 83%.

Emergency maintenance of outdoor equipment

Pain point: There is no crane in the field, and it is difficult to disassemble and assemble the diesel engine.

Weihua plan:

WH-FH10 hook + anti-sway chain.

The forklift moves to the fault point to lift the component.

Wert: Repair time shortened to 1/4.

| Project | Parameter value |

| Nennlast | 5,000 kg |

| Test load | 7,500 kg (1.5×SWL) |

| Selbstachtung | 78 kg |

| Suitable forklift lifting capacity | ≥ 5,000 kg |

| Maximum hook width | 100 mm |

| Drehwinkel | 360° manual lock |

| Arbeitstemperatur | -30℃ ~ +80℃ |

| Security certification | Ce, ISO 10535, Gb/t 10051.1 |

Q:Can the forklift crane hook be used as an ordinary fork?

A:cannot! This is an accessory specially designed for lifting. It is necessary to switch to the fork mode for pallet handling, and the switching time only takes 3 Sekunden.

Q:How do I confirm if my forklift can be installed?

A:Just provide: ① forklift model ② photo of attachment interface ③ hydraulic pressure value.

Weihua engineers will provide feedback on compatibility reports within 24 Std..

Q:How to control the center of gravity of the forklift during lifting?

A:Must comply with:

① The load is always directly in front of the fork.

② Lifting height ≤ 1/2 of vehicle height.

③ Install Weihua balance stabilizer (optional).

Wir schätzen Ihr Feedback! Bitte füllen Sie das folgende Formular aus, damit wir unsere Dienste auf Ihre spezifischen Anforderungen anpassen können.

Hauptmerkmale des Ramshorn-Kranhakens & Vorteile 1. Beispiellose Sicherheit: Die einzigartige t……

Entdecken Sie mehr →

Hauptmerkmale des C-Hakens des Coilhandhabungskrans Hohe Festigkeit & Stabilität: Weihuas Spule h......

Entdecken Sie mehr →

LKW -Kranhakenparameter Weihua Truck Crane Hooks müssen beide Lighs berücksichtigen ……

Entdecken Sie mehr →

Klicken Sie auf die Schaltfläche, um Produktinformationen und Angebote auf WhatsApp zu erhalten.

Holen Sie sich Zitat

Neueste Kommentare