Kdy vyměnit drátěné lano na jeřábu?

2025-10-09

Klíčová kritéria pro výměnu ocelového lana jeřábu (The “10-2-1” Rule is a good start)

A common and easy-to-remember guideline is the “10-2-1” Rule, but it’s just the beginning.

1. Broken Wires (The “10” and “2”)

- Random Broken Wires: The rope must be replaced if the number of randomly distributed broken wires in one rope lay (the length it takes for one strand to make a complete spiral around the core) reaches 10.

- Broken Wires in a Strand: If 2 or more broken wires are found in one strand within one rope lay, the rope must be replaced. This indicates a localized problem or “birdcaging” in that specific strand.

2. Wear and Corrosion (Reduction in Diameter)

- Loss of Metallic Cross-Section: Measure the rope diameter. If there is a loss of more than 1/3 of the original nominal diameter due to wear, koroze, or core failure, the rope must be replaced. This is a critical sign of strength loss.

3. Koroze (The “1”)

- Heavy Corrosion: The rope must be replaced if there is evidence of any pitting or severe corrosion that has weakened the rope. This is a standalone reason for replacement, regardless of broken wires.

Other Critical Reasons for Immediate Replacement

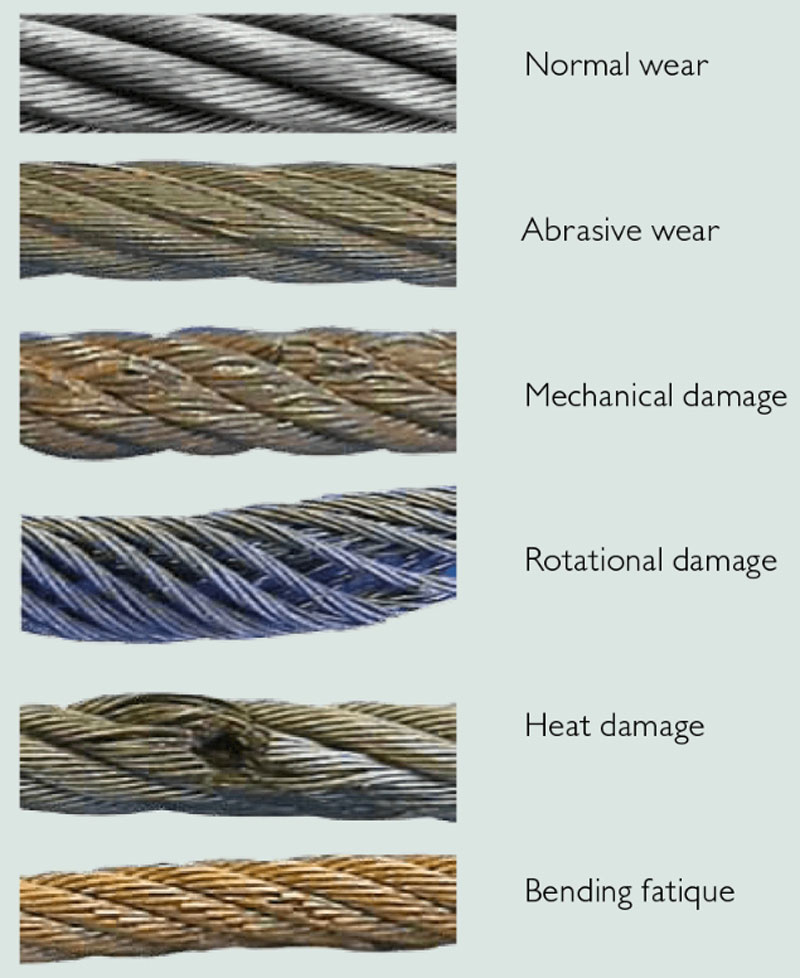

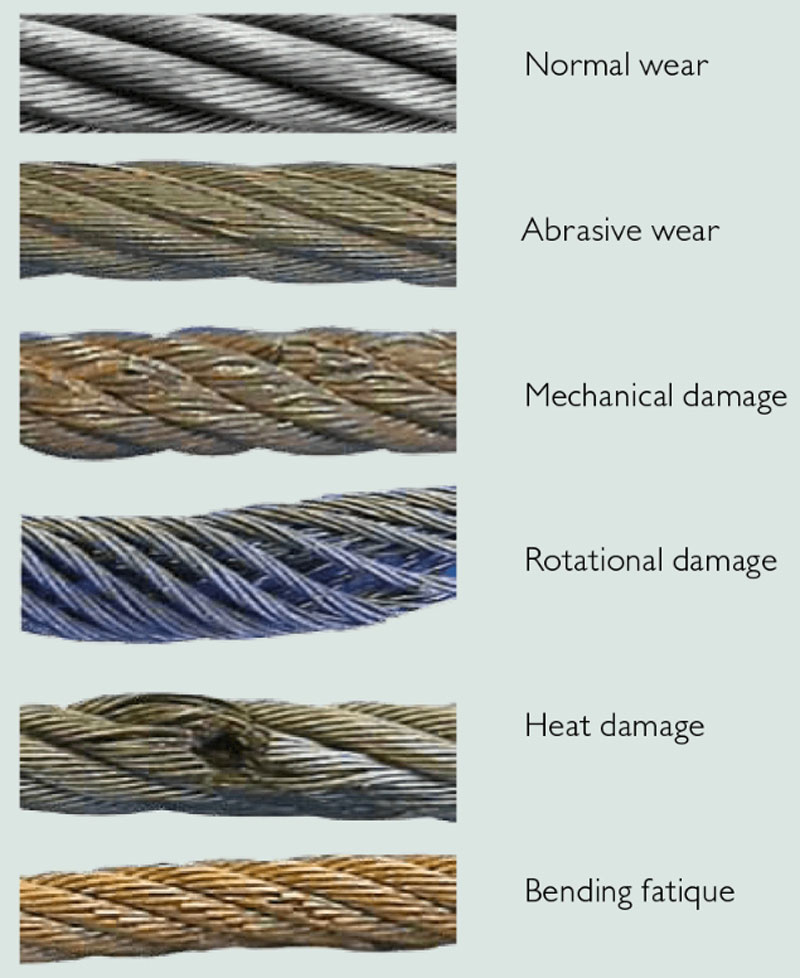

Beyond the “10-2-1” rule, look for these specific types of damage:

- 1. Poškození teplem: Any evidence of exposure to high heat (NAPŘ., from a fire or being near welding). This can be identified by a blue-black discoloration and loss of lubricant integrity. The rope’s strength is permanently compromised.

- 2. Kinking, Crushing, or Birdcaging: Any distortion that changes the rope’s geometry. A “kink” creates a permanent weak point. “Birdcaging” (where strands are forcibly pushed out from the core) indicates severe shock loading or mechanical damage.

- 3. Damaged or Pushed-Out Core (Core Protrusion): If the core is visibly protruding from the strands, the rope’s internal support is gone.

- 4. Electric Arc Damage: If the rope has been part of an electrical fault, it can have melted or burned spots, severely weakening it.

- 5. Severe Localized Wear (Scrubbing): Excessive wear at points where the rope contacts other ropes, drums, or sheaves, especially in a single spot.

- 6. Reduction of Rope Diameter at an End Fitting: This can indicate core failure or corrosion inside the socket.

- 7. Excessive Stretching: If the jeřábové lano has permanently elongated, it indicates that the wires have yielded and lost their strength.

Summary: When to Replace – Crane Wire Rope Quick Checklist

| Condition |

Action – REPLACE THE ROPE |

| 10 or more broken wires in one rope lay. |

YES |

| 2 or more broken wires in one strand in one rope lay. |

YES |

| Rope diameter is reduced by over 1/3 from its original size. |

YES |

| Any signs of severe corrosion or pitting. |

YES |

| Evidence of heat or electrical damage. |

YES |

| Kinks, zdrcující, chov ptáků, or any distortion. |

YES |

| Damaged end attachments (NAPŘ., cracks in sockets). |

YES |

| Core failure or protrusion. |

YES |

| Worn-out or cracked outer wires (even if not broken). |

Consult a qualified inspector immediately. |

Always follow the manufacturer’s guidelines and comply with local safety regulations (OSHA, ASME, atd.). Formal inspections must be performed by a designated and qualified person.

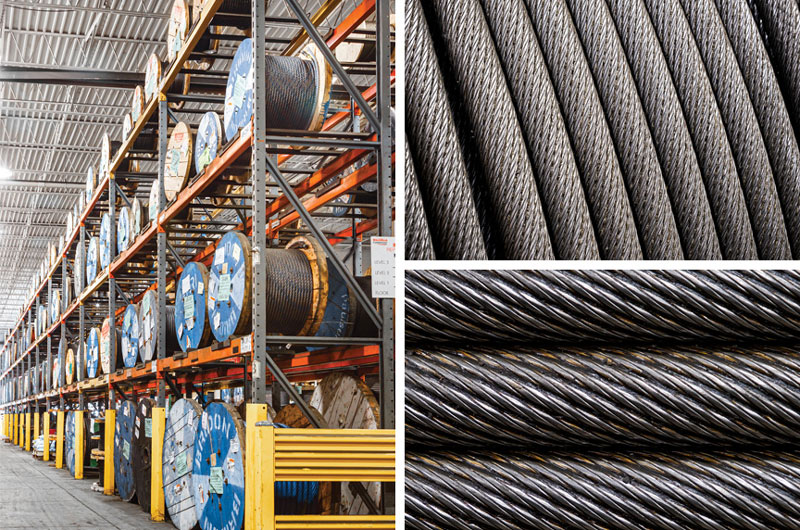

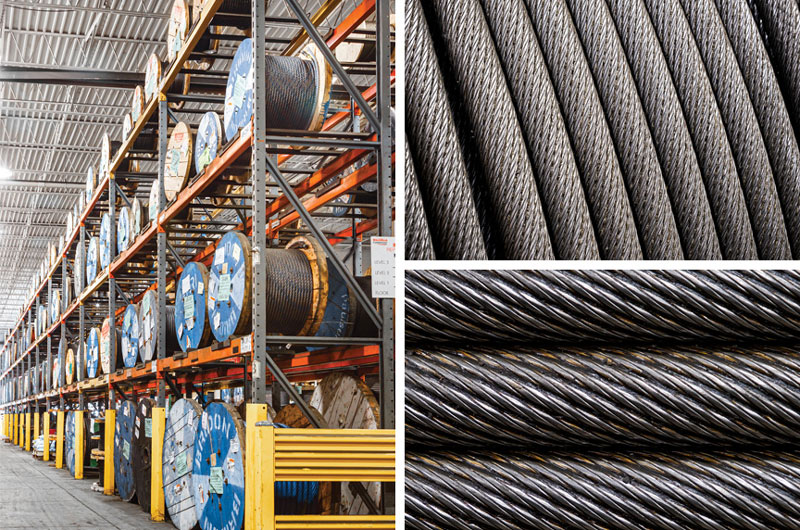

For detailed information on crane wire ropes, viz: Crane Wire Rope

Nejnovější komentáře