Náš těžký námořník HOOK CRANE je precizně zkonstruován pro přísné požadavky zvedacích operací v loděnicích. Zkonstruováno tak, aby zvládlo velké zatížení, odolávat drsnému mořskému prostředí, a zajistit maximální bezpečnost, tento hák je kritickým spojením mezi vaším jeřábem a nákladem – od motorových bloků a ocelových plátů až po lodní sekce a vybavení suchých doků.

1. Nekompromisní síla & Trvanlivost

Materiál: Kované z oceli z lehké slitiny s vysokou tendennou (Třída 100/slitina E), tepelně zpracované pro výjimečnou houževnatost.

Nakládací kapacita: Hodnoceno pro SWL (Bezpečné pracovní zatížení) z 5 na 500+ tuny. Zakázkové dostupné designy.

Odolnost proti korozi: Trojnásobně chráněno žárovým zinkováním, epoxidový nátěr námořní kvality, nebo nerezové varianty (316L).

2. Vylepšené bezpečnostní systémy

Bezpečnostní závora: Odpružená, manuál, nebo poloautomatické západky zabraňují náhodnému uvolnění.

Ochrana proti přetížení: Volitelné integrované snímače zatížení pro monitorování v reálném čase (V souladu s API).

Bezpečný design: Konstrukce odolná proti únavě podle MKP 9.511 a ISO 4301/EN 13889 standardy.

3. Optimalizováno pro námořní pracovní postupy

360° Rotace: Otočné háky eliminují kroucení ocelového lana při přesném polohování.

Nízkoprofilový design: Vyčistí stísněné prostory na palubě lodi, paluby, a konstrukce suchých doků.

Absorpce šoku: Pružná axiální ložiska snižují dynamické namáhání při těžkých zdvihech.

4. Chytrá kontrola & Údržba

Indikátory opotřebení: Vizuální značky zvýrazňují kritické oblasti opotřebení (hrdlo, tip).

Fitinky Easy-Grease: Mazací otvory prodlužují životnost ložisek/šroubů.

Sledovatelnost: Laserem vyleptané ID se SWL, sériové číslo, a podrobnosti o certifikaci.

| Parametr | Specifikace |

| Modelová řada | MCH-SY (Norma) / MCH PLUS (Moderní) |

| Bezpečné pracovní zatížení (SWL) | 5– 500 tun |

| Bezpečnostní faktor návrhu | ≥ 5:1 (pro ISO 4301) |

| Materiál | Legovaná ocel (Třída 100/slitina E) |

| Proces kování | Zápustkové kování, testováno ultrazvukem |

| Tepelné zpracování | Uhasit & temperované (HRC 38-42) |

| Ochrana proti korozi | Třívrstvá: Zn-fosfátování + HDG + epoxidový nátěr (250μm) |

| Otáčení | 360° plynulé otáčení |

| Typ ložiska | Axiální kuželíkové ložisko (mazané tukem) |

| Bezpečnostní závora | Odpružená (norma), poloautomatický, nebo zapnutý RFID senzor |

| Provozní teplota. | -40°C až +150 °C |

| Únavový život | 500,000 cykly @ 60% SWL (ISO 4301-5) |

| Limit opotřebení | Max 10% zmenšení hrdla / 5% deformace hrotu háčku (ASME B30.10) |

| Požadavky NDT | MPI každý 6 měsíce; UT pro háčky >100 tuny |

| Certifikace | DNV-GL, Abs, Lloyd's Register, CCS, IRS |

| Rozměry (Příklad) | *MCH-SY 100 tun:* – Krk: 320 mm – Šířka: 180 mm – Výška: 785 mm |

Řešení na míru pro komplexní výtahy:

| Požadavek | Naše schopnosti |

| Extrémní prostředí | Háčky arktické kvality (-60° C.), výbušná atmosféra (ATEX) varianty |

| Nestandardní zatížení | Asymetrické háky pro úhlové výtahy, ergonomické rukojeti pro jemné součásti |

| Automatizace připravena | Robotické podložky rozhraní, samosvorné senzory, dálková zátěžová telemetrie |

| Retrofit sady | Starší vylepšení jeřábu s digitálními snímači zatížení + antikolizní systémy |

| Funkce | Technická hodnota | Kompatibilita |

| Integrovaný snímač zatížení | přesnost ±0,5 %., 4-20výstup mA/RS485 | API 9B/ISO 17025 certifikovaný |

| Anti-Sway systém | Aktivní tlumení gyra (doba odezvy: <0.8 sek) | Integrace PLC jeřábu připravena |

| RFID monitorování | Štítky ISO 18000-6C (paměť: 8 KB) | Synchronizováno s EAM/CMMS |

| Certifikace ATEX | Zóna 1/21 (IIB+H2 T85°C) | Západky odolné proti výbuchu |

| Adaptér pro rychlou výměnu | Rozhraní vyhovující normě DIN 15403 | Pro úlovky, pouta, nebo magnety |

1. Háčkové bloky & Shromáždění

Tandemové háky: Vícehákové rozpěrné nosníky pro vyvážené zvedání nepravidelných břemen (NAPŘ., lodní moduly).

Rotující kladky: Integrované systémy kladek snižují otěr drátu + umožnit vertikální rýhování (ISO 4309 vyhovující).

Technologie Anti-Sway: Gyroskopicky stabilizované háky s inerciálními tlumiči pro přesné umístění ve větrných docích.

2. Chytré přílohy

RFID značení: Bezdrátové sledování zátěže + automatizované kontrolní protokoly (kompatibilní s platformami IoT jeřábů).

Vision-Assist sady: Vestavěné kamery + LiDAR pro sledování mrtvého úhlu během výtahů v omezeném prostoru.

Adaptéry pro rychlou výměnu: Vyměnitelné hlavice háku (Clevis, urvat, spoutat) pro rychlé přepínání úkolů.

1. Dry-Dock Lifting: Části trupu, vrtulí, kormidla.

2. Výroba obchodů: Ocelové plechy, stojany na trubky, stroje.

3. Vybavení Quays: Instalace motoru, modulární kabiny.

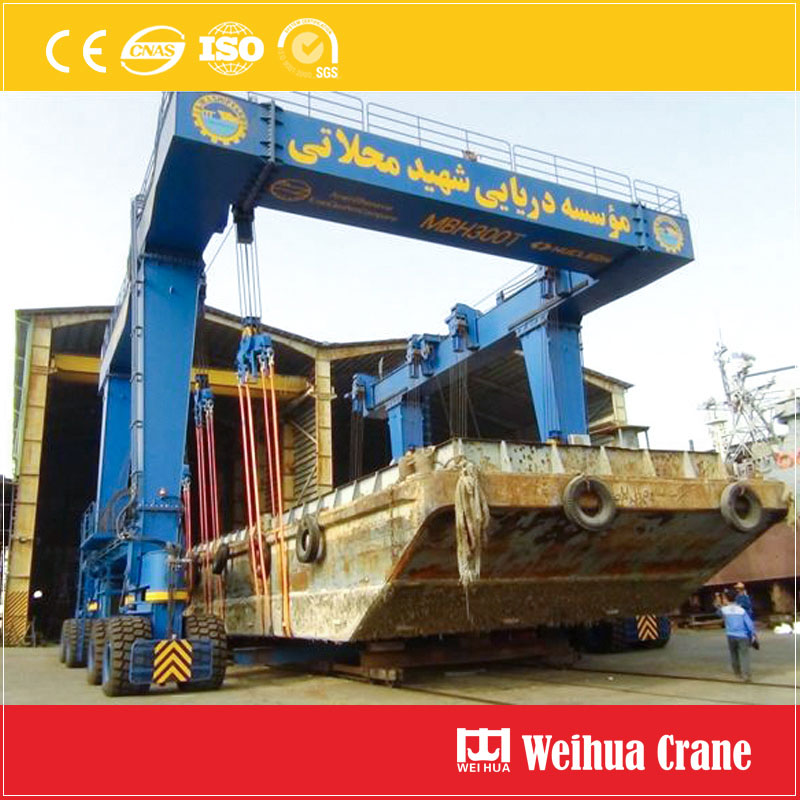

4. Těžká doprava: Provoz portálového jeřábu, nakládky.

Dědictví s nulovým selháním: 200,000+ hodin provozní spolehlivost v globálních loděnicích.

Zakázkové inženýrství: Přizpůsobené délky stopky, západky, nebo RFID tagy pro digitální správu vozového parku.

Globální dodržování předpisů: Certifikováno pro EU, NÁS, asijské námořní bezpečnostní režimy.

Vyžádejte si cenovou nabídku nebo technickou dokumentaci

Vylepšete svou bezpečnost při zvedání pomocí háčků vyrobených tak, aby vydržely sůl, bouře, a napětí. Pro diagramy zatížení kontaktujte náš technický tým, CAD modely, a rychlé prototypování.

Vážíme si vaší zpětné vazby! Vyplňte prosím níže uvedený formulář, abychom mohli přizpůsobit naše služby vašim konkrétním potřebám.

Kliknutím na tlačítko získáte informace o produktu a nabídky na WhatsApp.

Získejte citát

Nejnovější komentáře