الرافعة العلوية ذات العارضة المزدوجة عبارة عن معدات قوية لمعالجة المواد مصممة لرفع ونقل الأحمال الثقيلة في البيئات الصناعية.

الرافعة العلوية ذات العارضة المزدوجة عبارة عن معدات قوية لمعالجة المواد مصممة لرفع ونقل الأحمال الثقيلة في البيئات الصناعية. تم تصميمها باستخدام عوارض رئيسية متوازية, فهو يوفر ثباتًا فائقًا وقدرة تحمل للحمل مقارنةً بنماذج العارضة الواحدة, مما يجعلها الاختيار الأمثل للتطبيقات الثقيلة مثل مصانع الصلب, مصانع التصنيع, المستودعات, ومواقع البناء. ما إذا كنت بحاجة إلى نقل الآلات, مواد خام, أو المنتجات النهائية, تجمع الرافعات العلوية ذات العارضة المزدوجة لدينا بين الدقة, متانة, والسلامة لتحسين سير العمل الخاص بك.

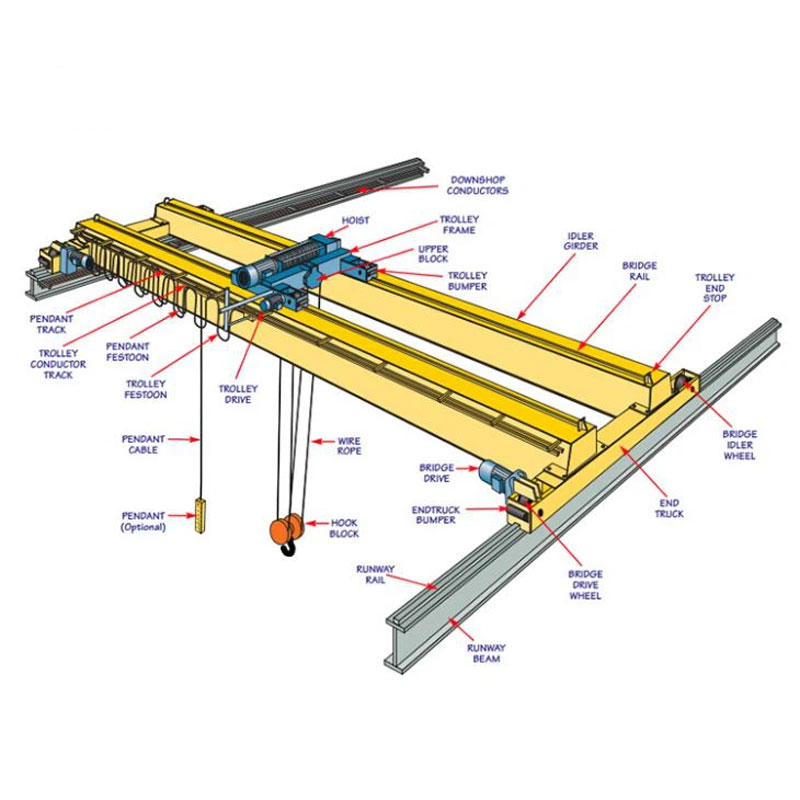

الرافعة العلوية ذات العارضة المزدوجة هي نوع من الرافعات الجسرية التي تتكون من عارضتين رئيسيتين أفقيتين مدعومتين بشاحنات نهاية (أو نهاية العربات) التي تعمل على طول القضبان المرتفعة (مدارج) مثبتة على أعمدة البناء أو الهياكل المستقلة. يتم تركيب آلية رفع الرافعة - عادة رافعة أو عربة - على عربة تسير على طول العوارض الرئيسية, السماح بتغطية 360 درجة لمساحة العمل أدناه.

على عكس الرافعات العلوية ذات العارضة الواحدة, والتي تعتمد على شعاع رئيسي واحد, تعمل تصميمات العارضة المزدوجة على توزيع الوزن بشكل أكثر توازناً, لتمكينهم من التعامل مع الأحمال الثقيلة (في كثير من الأحيان يصل إلى 500 طن أو أكثر). وهذا يجعلها ضرورية للصناعات التي تتطلب رفع الأحمال الثقيلة بشكل متكرر, حيث الموثوقية والسلامة غير قابلة للتفاوض.

تم تصميم الرافعات العلوية ذات العارضة المزدوجة لدينا لتتفوق في البيئات الصعبة. وهنا ميزاتهم البارزة:

|

المعلمة

|

النطاق/التفاصيل

|

|

قدرة الرفع القصوى

|

10 طن – 500 طن (الخيارات المخصصة المتاحة للأحمال العالية)

|

|

طول الامتداد

|

10م – 35 م (يمتد مخصص عند الطلب)

|

|

رفع الارتفاع

|

6م – 30 م (قابل للتعديل على أساس التطبيق)

|

|

سرعة الرافعة

|

0.5م/دقيقة – 10 م/دقيقة (سرعة متغيرة مع خيار عاكس التردد)

|

|

سرعة سفر العربة

|

5م/دقيقة – 30 م/دقيقة

|

|

سرعة سفر الرافعة

|

10م/دقيقة – 50 م/دقيقة

|

|

الطبقة العاملة

|

A5 – A8 (معيار ISO; مناسبة للضوء للخدمة الشاقة, الاستخدام المستمر)

|

|

مزود الطاقة

|

380فولت/3PH/50 هرتز (قابلة للتخصيص لـ 220 فولت/440 فولت أو مناطق أخرى)

|

|

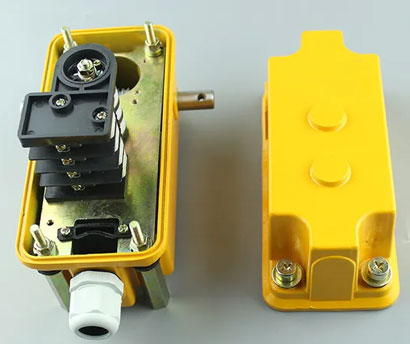

وضع التحكم

|

سيطرة قلادة, التحكم عن بعد (لاسلكي), أو التحكم في المقصورة

|

تتكون الرافعة العلوية ذات العارضة المزدوجة من عدة مكونات رئيسية تعمل معًا لضمان كفاءة الرفع والحركة:

العوارض الرئيسية

عوارض فولاذية متوازية (عوارض) التي تشكل هيكل الجسر. إنهم يتحملون حمولة العربة والمواد المرفوعة, تتطلب قوة وصلابة عالية.

نهاية الشاحنات

يتم تركيبها على طرفي العوارض الرئيسية, تحتوي هذه العجلات والمحركات التي تدفع الرافعة على طول قضبان المدرج.

عربة

وحدة متحركة تنتقل على طول العوارض الرئيسية أو أسفلها. إنها تحمل الرافعة وتعمل بمحرك خاص بها للحركة الأفقية.

رفع

آلية الرفع, بما في ذلك أ طبل الرافعة, حبل سلكي/كابل, و خطاف الرافعة. وهي المسؤولة عن رفع وخفض الأحمال, مع خيارات التشغيل الكهربائي أو الهيدروليكي.

النظام الكهربائي

يشمل المحركات, لوحات التحكم, مفاتيح, والأسلاك لتشغيل الرافعة وتشغيلها, عربة, ورافعة.

محددات الزائد, مفاتيح حدود السفر, أنظمة التوقف في حالات الطوارئ, وأجهزة مضادة للتأثير لضمان التشغيل الآمن.

س 1: ما هو الفرق بين الرافعة العلوية ذات العارضة المزدوجة والرافعة العلوية ذات العارضة الواحدة؟?

أ: تحتوي الرافعات ذات العارضة المزدوجة على عارضتين رئيسيتين, تقدم قدرة تحميل أعلى (10+ طن) والاستقرار, مما يجعلها مناسبة للاستخدام الشاق. الرافعات ذات العارضة الواحدة لها عارضة رئيسية واحدة, أخف وزنا, وأفضل للأحمال الخفيفة (حتى 10 طن) في مساحات عمل أصغر.

Q2: ما هي الصناعات التي تستخدم الرافعات العلوية ذات العارضة المزدوجة?

أ: يتم استخدامها على نطاق واسع في مصانع الصلب, تصنيع السيارات, أحواض بناء السفن, مواقع البناء, المستودعات (للتعامل مع البليت الثقيلة), ومحطات الطاقة.

س 3: كم مرة يجب صيانة الرافعة العلوية ذات العارضة المزدوجة?

أ: عمليات التفتيش الروتينية (الشيكات اليومية لارتداء, تشحيم) والصيانة المهنية (كل 6-12 شهرًا) يوصى بها لضمان السلامة وطول العمر.

س 4: هل يمكن تخصيص الرافعات ذات العارضة المزدوجة لتطبيقات محددة?

أ: نعم. نحن نقدم التخصيصات لسعة التحميل, فترة, ارتفاع الرفع, أنظمة التحكم, والمرفقات المتخصصة (على سبيل المثال, مغناطيس للتعامل مع المعادن, الاستيلاء على المواد السائبة).

س 5: هل الرافعات العلوية ذات العارضة المزدوجة متوافقة مع معايير السلامة الدولية?

أ: رافعاتنا تلبي معايير ISO, فيم, ومعايير OSHA, مع ميزات أمان مدمجة لضمان الامتثال للوائح الصناعية العالمية.

شارك مع PDF: تحميل

نحن نقدر ملاحظاتك! يرجى إكمال النموذج أدناه حتى نتمكن من تخصيص خدماتنا حسب احتياجاتك المحددة.

Product Overview Designed specifically for the harsh and demanding conditions of materi……

اكتشف المزيد →

مقدمة ل 3 طن رافعة علوية أ 3 الرافعة العلوية طن متعددة الاستخدامات, صناعة……

اكتشف المزيد →

As a core equipment in bulk material handling scenarios, the grab overhead crane is spec……

اكتشف المزيد →

أحدث التعليقات