ال 30 الرافعة العلوية طن هي معدات معالجة المواد الأساسية المصممة للتطبيقات الصناعية المتوسطة إلى الثقيلة.

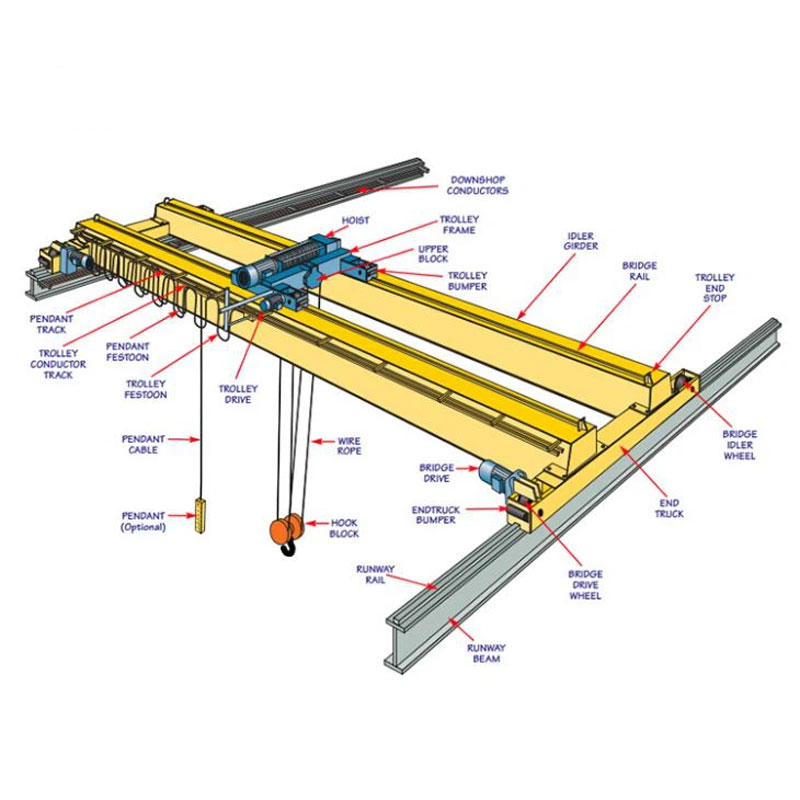

ال 30 الرافعة العلوية طن هي معدات معالجة المواد الأساسية المصممة للتطبيقات الصناعية المتوسطة إلى الثقيلة. يتفوق في الرفع, يتحرك, وتحديد المواقع الأحمال تصل إلى 30 طن بدقة عالية, استقرار, والسلامة, مما يجعلها أصلاً لا غنى عنه للصناعات التي تتطلب نقلًا فعالاً للأحمال الثقيلة. سواء في ورش التصنيع, محطات توليد الطاقة, أو ساحات لوجستية, تعمل هذه الرافعة على تحسين سير العمل, يقلل من كثافة العمل اليدوي, ويضمن كفاءة تشغيلية متسقة.

ال 30 الرافعة العلوية طن تدمج الهندسة المتقدمة, تصميم السلامة, ووظائف سهلة الاستخدام, مع المزايا الرئيسية التالية:

|

فئة المعلمة

|

تفاصيل المواصفات

|

|

قدرة الرفع المقدرة

|

30 طن (الخطاف الرئيسي); 5-10 طن (هوك مساعد, خياري)

|

|

نطاق سبان

|

10 م - 31.5 م (قابلة للتخصيص لورش العمل الخاصة)

|

|

رفع الارتفاع

|

6 م - 30 م (قابلة للتخصيص على أساس ارتفاع ورشة العمل)

|

|

سرعة رفع (هوك الرئيسي)

|

0.8 - 8 م/بلدي (تردد متغير, تنظيم بلا خطوات)

|

|

سرعة رفع (هوك أوكس)

|

2 - 16 م/بلدي (إذا كانت مجهزة)

|

|

سرعة السفر الطولية (رافعة)

|

20 - 40 م/بلدي (تردد متغير)

|

|

سرعة السفر العرضية (عربة)

|

10 - 20 م/بلدي (تردد متغير)

|

|

الطبقة العاملة

|

A5 – A7 (A5: متوسطة الخدمة, 1,000 ساعات العمل / سنة; أ7: الثقيلة, 4,000 ساعات العمل / سنة)

|

|

مزود الطاقة

|

380الخامس/50 هرتز/3Ph (قابلة للتخصيص لـ 415 فولت/60 هرتز للأسواق الدولية)

|

|

الوزن الإجمالي

|

15 - 35 طن (يختلف حسب الامتداد وارتفاع الرفع)

|

|

قوة المحرك (الرفع)

|

18.5 - 37 KW (الخطاف الرئيسي); 5.5 - 11 KW (هوك مساعد, خياري)

|

|

قوة المحرك (السفر الطولي)

|

2×7.5 – 2×15 كيلو واط (محرك واحد لكل شعاع نهاية)

|

|

قوة المحرك (السفر المستعرض)

|

1×3 – 1×7.5 كيلو واط

|

ال 30 يتم استخدام الرافعة العلوية للطن على نطاق واسع في الصناعات التي تتطلب التعامل مع الأحمال الثقيلة, بفضل قدرته على التكيف مع بيئات العمل المختلفة:

بينما يتعامل كلا النموذجين 30 طن, تختلف تصميماتها الهيكلية وسيناريوهات التطبيق بشكل كبير. ويقارن الجدول التالي الجوانب الرئيسية:

|

البعد المقارنة

|

عارضة واحدة 30 طن رافعة علوية

|

العارضة المزدوجة 30 طن رافعة علوية

|

|

التصميم الهيكلي

|

شعاع رئيسي واحد (I-beam أو شعاع الصندوق) مدعومة بعوارض نهائية.

|

عوارض رئيسية متوازية (عوارض الصندوق) متصلة بواسطة الحزم المتقاطعة.

|

|

القدرة على التكيف

|

الحد الأقصى للامتداد ≥ 22 م (محدودة بقدرة تحمل شعاع واحد).

|

أقصى مدى ≥ 31.5 م (مناسبة لورش العمل/الساحات الكبيرة).

|

|

رفع الارتفاع

|

عمومًا 6 - 18 م (محدودة بمساحة تركيب العربة).

|

عمومًا 10 - 30 م (مساحة رأسية أكبر لحركة العربة).

|

|

إشغال الفضاء

|

انخفاض الإرتفاع (يحفظ ارتفاع ورشة العمل); حجم إجمالي أصغر.

|

ارتفاع أعلى (يتطلب ورش عمل أطول); بصمة أكبر.

|

|

الاستقرار التشغيلي

|

الاستقرار المعتدل (عرضة لانحراف شعاع طفيف تحت الأحمال الثقيلة).

|

استقرار عالي (عوارض مزدوجة توزع الحمل بالتساوي, الحد الأدنى من الانحراف).

|

|

تردد التحميل

|

مناسبة لعمليات التردد المتوسط (≤ 1,500 دورات / سنة).

|

مناسبة للعمليات عالية التردد (≥ 3,000 دورات / سنة).

|

|

يكلف

|

انخفاض التكلفة الأولية (30% - 50% أرخص من العارضة المزدوجة).

|

ارتفاع التكلفة الأولية (ولكن انخفاض تكاليف الصيانة على المدى الطويل للاستخدام المكثف).

|

|

التكوينات الاختيارية

|

محدود (هوك مساعد, التحكم عن بعد فقط).

|

متنوع القدرات (هوك مساعد, الاستيلاء على دلو, مغناطيس, نظام مضاد للسيرة, إلخ.).

|

|

السيناريوهات المثالية

|

ورش عمل صغيرة ومتوسطة, التعامل مع الأحمال الثقيلة ذات التردد المنخفض (على سبيل المثال, مصانع الآلات الصغيرة).

|

ورش عمل كبيرة, التعامل مع الأحمال الثقيلة عالية التردد (على سبيل المثال, مصانع الصلب, محطات توليد الطاقة).

|

س 1: ما هي العوامل التي يجب مراعاتها عند اختيار أ 30 طن رافعة علوية?

A1: وتشمل العوامل الرئيسية:

Q2: كم مرة يفعل أ 30 طن رافعة علوية تتطلب الصيانة?

A2: تتبع الصيانة جدولًا زمنيًا من ثلاثة مستويات:

س 3: يمكن 30 يتم تخصيص طن رافعة علوية لتلبية الاحتياجات الخاصة?

A3: نعم. تشمل التخصيصات الشائعة:

س 4: ما هي شهادات السلامة الإلزامية 30 طن من الرافعات العلوية?

A4: تختلف الشهادات حسب المنطقة, ولكن تلك الرئيسية تشمل:

س 5: ما هي مدة خدمة أ 30 طن رافعة علوية?

A5: في ظل الاستخدام العادي والصيانة المناسبة, عمر الخدمة هو 10 - 15 سنين. وتشمل العوامل الرئيسية التي تؤثر على الحياة:

ال 30 تجمع الرافعة العلوية طنًا بين القوة, أمان, والمرونة لتلبية الاحتياجات المتنوعة للتعامل مع مواد الصناعة الثقيلة. مع تصاميم قابلة للتخصيص وأداء موثوق, إنه استثمار طويل الأجل لتحسين الكفاءة التشغيلية وضمان السلامة في مكان العمل. لمزيد من التفاصيل حول النماذج, يقتبس, أو حلول مخصصة, يرجى الاتصال بفريقنا الفني.

نحن نقدر ملاحظاتك! يرجى إكمال النموذج أدناه حتى نتمكن من تخصيص خدماتنا حسب احتياجاتك المحددة.

In the realm of heavy-duty material handling, the double trolley gantry crane stands ou……

اكتشف المزيد →

ال 50 طن من القنطرة المطاطية المتعبة (آر تي جي) الرافعة عبارة عن معدات مناولة مواد عالية الأداء……

اكتشف المزيد →

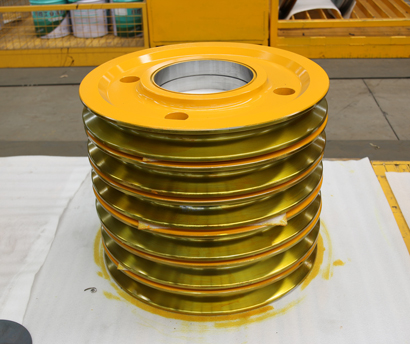

Product Overview The crane wire rope pulley is a critical component in lifting machiner……

اكتشف المزيد →

أحدث التعليقات