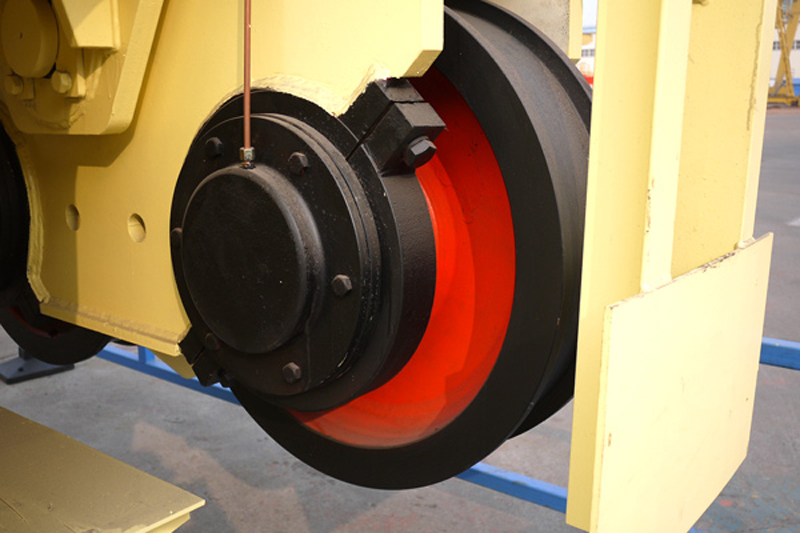

Gantry crane wheels are responsible for bearing the entire load of the crane, including the hoisted materials, and facilitating smooth, آمن, and efficient longitudinal travel along the defined path. Engineered for extreme durability and performance, these wheels directly impact the crane’s operational safety, longevity, and noise levels. Manufactured from high-strength alloys and subjected to rigorous heat treatment, our gantry crane wheels are designed to withstand immense pressure, shock loads, and abrasive wear in the most demanding industrial environments, from steel mills and shipping ports to heavy fabrication workshops.

1. Exceptional Durability & ارتداء المقاومة

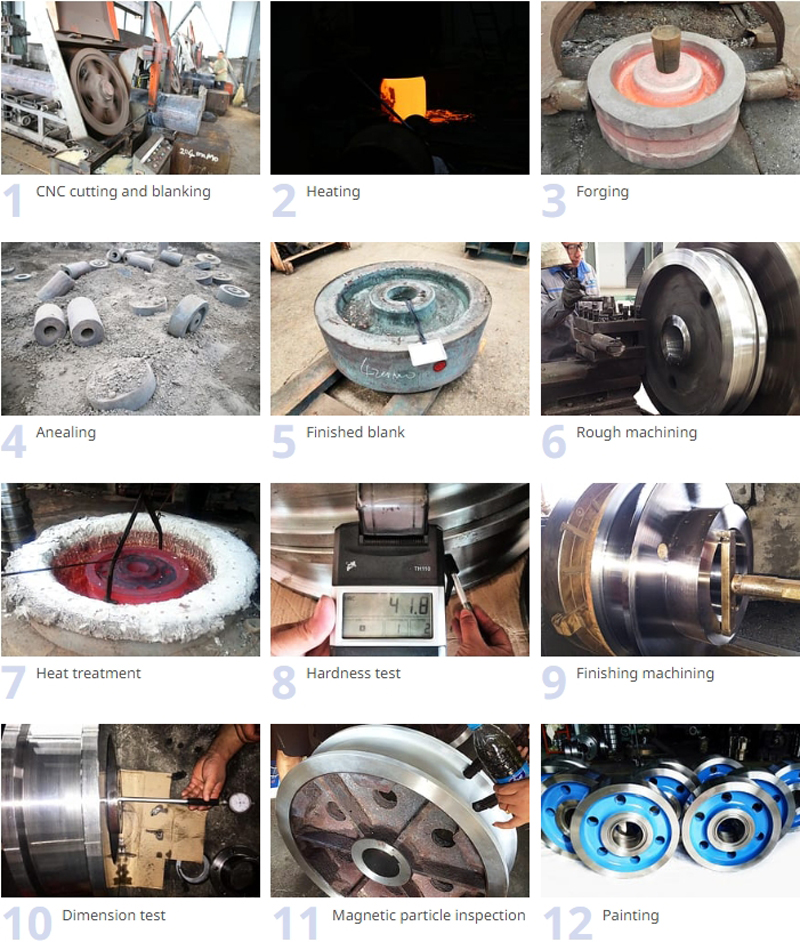

Forged from high-carbon steel or alloy steel (على سبيل المثال, 65MN, 42CRMO), our wheels offer superior tensile strength and hardness.

Advanced heat treatment processes like quenching and tempering create a hard, wear-resistant outer surface (rim) while maintaining a tough, shock-absorbing core.

2. High Load-Bearing Capacity

Precisely engineered to handle static and dynamic loads, ensuring stable performance under the full rated capacity of the crane without deformation.

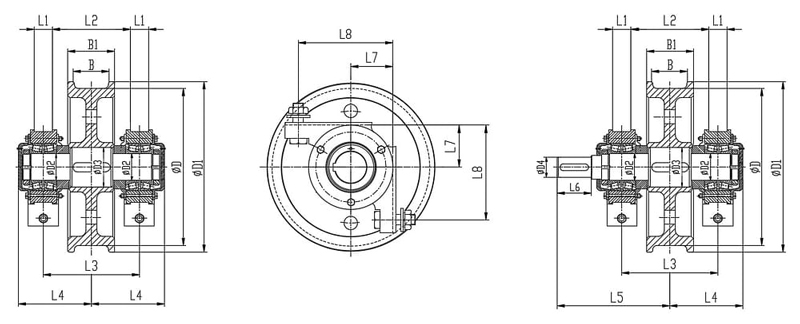

3. Optimized Tread Profile & Flange Design

The tread profile is machined to perfectly match the contour of the crane rail (على سبيل المثال, ARA, KRUPP, flat rail), ensuring maximum contact area and reducing point stress.

The flange is designed to provide secure guidance, preventing derailment while minimizing friction and wear against the rail side.

4. الآلات الدقيقة

Each wheel undergoes precision machining and grinding to achieve strict tolerances on diameter, concentricity, and surface finish. This ensures smooth rotation, reduces vibration, and extends the life of both the wheel and the rail.

5. مقاعد تحمل قوية

The bore and keyway are accurately machined to ensure a perfect fit with the axle and bearings, guaranteeing efficient power transmission and preventing slippage or premature failure.

6. خيارات التخصيص

We provide fully customizable wheels tailored to your specific requirements, including diameter, width, bore size, flange height, and material grade to suit your unique gantry crane model and application.

The following table provides standard specifications. Custom dimensions and materials are available upon request.

| المعلمة | نطاق المواصفات | ملحوظات |

|---|---|---|

| قطر العجلة | 250 – 1000+mm | أقطار مخصصة متاحة |

| Tread Width | 90 – 200+mm | Matched to rail head width |

| قطر تتحمل | 80 – 200+mm | Precision machined with keyway |

| ارتفاع شفة | 25 – 45mm | Standard or as per requirement |

| درجة المادة | 65MN, 42CRMO, 55# فُولاَذ, C45 | Other alloy steels available |

| صلابة السطح | 45 - 60 لجنة حقوق الإنسان | Achieved through heat treatment |

| صلابة الأساسية | 240 - 280 غ.ب | يضمن المتانة ومقاومة التأثير |

| الأعلى. Wheel Load | 5 - 100+ طن | Per wheel, dependent on configuration |

Gantry crane wheels are categorized based on their flange type and material/construction.

1. عجلات شفة مزدوجة:

2. عجلات ذات شفة واحدة:

3. Flangeless Wheels:

1. عجلات فولاذية مزورة:

Manufactured through a forging process that aligns the grain structure, resulting in superior strength, مقاومة التأثير, and fatigue life. They are the premium choice for heavy-duty and high-cycle applications.

2. Cast Steel Wheels:

Made by pouring molten steel into a mold. A cost-effective solution for standard-duty applications. The quality is highly dependent on the casting process to avoid internal defects.

3. عجلات من سبائك الصلب:

Made from steel alloys like 42CrMo or 65Mn, which provide an excellent balance of high surface hardness and deep toughness after heat treatment. This is the most common and recommended material for industrial gantry cranes.

4. Case-Hardened Wheels:

Undergo a specific heat treatment (على سبيل المثال, carburizing) to create an extremely hard, wear-resistant surface layer while retaining a soft, ductile core. Excellent for applications with very high wear and rolling contact fatigue.

س 1: What is the primary function of a gantry crane wheel?

أ: The gantry crane wheel is a fundamental component that serves two main purposes: to support the full weight (حمولة) of the gantry crane and its lifted materials, and to guide the crane smoothly and safely along the runway rails.

Q2: How often should gantry crane wheels be inspected?

أ: We recommend a visual inspection before each shift for signs of wear, تشققات, أو الضرر. رسمي, detailed inspection should be conducted monthly by a qualified technician. The exact frequency depends on the crane’s duty cycle, load intensity, and operating environment.

س 3: What are the common signs of a failing crane wheel?

أ: Common warning signs include:

س 4: How do I choose the right material for my crane wheel?

أ: The choice depends on your application’s demands:

س6: How is the maximum wheel load calculated?

أ: The maximum wheel load is a calculated value based on the crane’s total weight, its lifting capacity, the number of wheels, and the load distribution. It is a critical safety parameter. Our engineering team can assist in verifying the required wheel load capacity for your system.

All specifications and data provided are for reference purposes. The final design and specifications must be confirmed based on the specific gantry crane model, duty class, and operational conditions. Contact our engineering team for a tailored solution.

نحن نقدر ملاحظاتك! يرجى إكمال النموذج أدناه حتى نتمكن من تخصيص خدماتنا حسب احتياجاتك المحددة.

نظرة عامة على المنتج ال 40 tons double girder overhead crane is a heavy-duty material han……

اكتشف المزيد →

أنواع الرافعات العلوية للمستودعات وتطبيقاتها 1. عارضة علوية واحدة كروم……

اكتشف المزيد →

As a high-performance heavy-duty lifting equipment, ال 60 طن رافعة علوية (also kn……

اكتشف المزيد →

أحدث التعليقات