عندما يتعلق الأمر بمعدات الرفع الثقيلة, أ كتلة ربط الرافعة يعد أحد أهم المكونات الأساسية التي تضمن التعامل الآمن والفعال مع الأحمال. يعد فهم التصميم وتفاصيل الرسم الخاصة بكتلة خطاف الرافعة أمرًا بالغ الأهمية للمهندسين, مشغلي, وفرق الصيانة على حد سواء. في هذا بلوق وظيفة, سنشرح ما أ ربط الرافعة وكتلة يكون, مكوناته النموذجية, كيفية قراءة رسم كتلة خطاف الرافعة, ولماذا تعد الرسومات الدقيقة أمرًا حيويًا في صناعة الرفع.

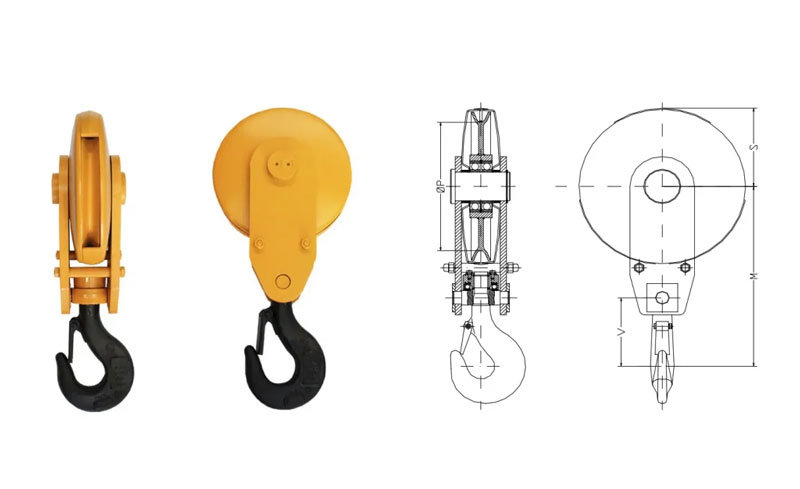

أ كتلة ربط الرافعة عبارة عن مجموعة تتضمن خطاف رافعة, الحزم (البكرات), إطار كتلة, محامل, ومزالج السلامة. تتصل هذه الكتلة بالحبل السلكي أو سلسلة الرافعة للرافعة وتنقل قوة الرفع إلى الحمولة. من خلال دمج الحزم المتعددة, تعمل كتلة الخطاف على تقليل التوتر على الحبل السلكي, مما يسمح برفع الأحمال الثقيلة بجهد أقل وتحسين السلامة.

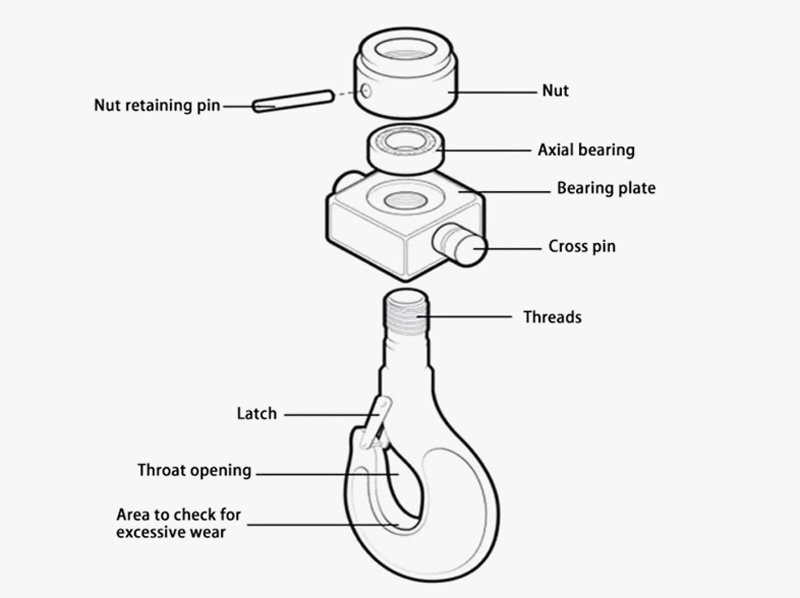

دقيق رسم كتلة هوك الرافعة سيُظهر عادةً جميع المكونات والأبعاد المهمة. فيما يلي العناصر الرئيسية المضمنة عادة:

خطاف: العنصر الحامل الرئيسي, عادة ما تكون مصنوعة من الفولاذ عالي القوة ومزودة بمزلاج أمان.

الحزم: عجلات محززة لتوجيه الحبل السلكي وتمكين الميزة الميكانيكية.

إطار الكتلة: السكن الذي يحمل الحزم ويربط معًا.

المحامل والمحاور: تمكين الدوران السلس للحزم.

مزلاج السلامة: يمنع الحمل من الانزلاق عن الخطاف عن طريق الخطأ.

تجميع دوار (خياري): يسمح للخطاف بالتدوير بحرية, تجنب التواء الحبل.

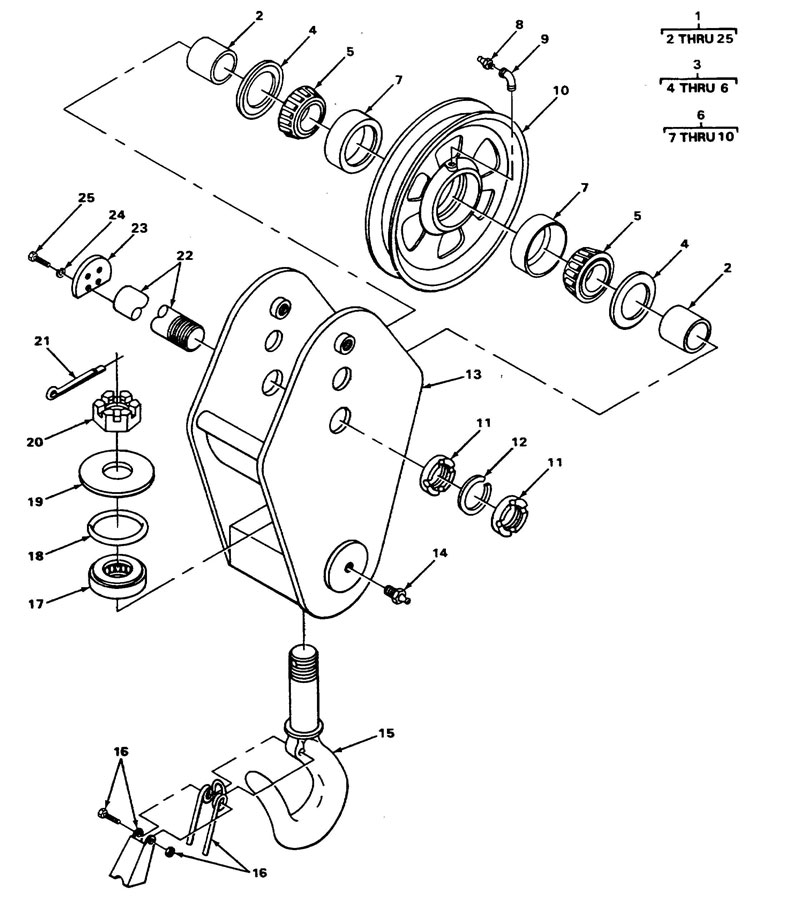

سيوفر الرسم التفصيلي لكتلة خطاف الرافعة أبعادًا لكل جزء, مواصفات المواد, تقييمات الحمل, وتعليمات التجميع.

القراءة أ رسم كتلة هوك الرافعة يتطلب معرفة الرسم الميكانيكية الأساسية. وهنا بعض النصائح:

1. فهم وجهات النظر: الرسومات غالبا ما تشمل الجبهة, جانب, وأعلى وجهات النظر من أجل الوضوح.

2. تحقق من الأبعاد: ابحث عن الأبعاد الشاملة, أقطار الحزم, فتح الحلق هوك, وأحجام تحمل.

3. تحديد تقييمات التحميل: تأكد دائمًا من أن كتلة الخطاف تلبي متطلبات قدرة الرفع للرافعة الخاصة بك.

4. المواد والمعايير: تحدد الرسومات الجيدة درجات المواد والامتثال لمعايير الصناعة (على سبيل المثال, من, ISO).

5. ملاحظات التجميع: انتبه إلى الملاحظات حول التشحيم, عزم الدوران الترباس, وفحوصات السلامة.

دقيق رسومات كتلة ربط الرافعة حاسمة لعدة أسباب:

1. أمان: تعمل الكتل المصممة والمصنعة بشكل صحيح على تقليل مخاطر الأعطال الميكانيكية.

2. صيانة: تساعد الرسومات الواضحة الفنيين على استبدال الأجزاء بشكل صحيح وإجراء عمليات الفحص الروتينية.

3. التخصيص: يمكن للمهندسين تكييف تصميمات كتلة الخطاف لتطبيقات محددة, مثل الرفع البحري أو الرافعات البرجية ذات القدرة العالية.

4. امتثال: يجب على المصنعين والمشغلين اتباع معايير صارمة لتلبية المتطلبات التنظيمية وشروط التأمين.

س 1: ما هو استخدام كتلة ربط الرافعة?

A1: خطاف الرافعة عبارة عن مجموعة تربط حبل سلك الرافعة بالحمل. يتضمن الحزم التي تضاعف قدرة الرفع, خطاف لعقد الحمل, ومكونات السلامة لضمان الرفع الآمن.

Q2: ما سبب أهمية رسم كتلة خطاف الرافعة التفصيلية?

A2: يضمن الرسم التفصيلي تصميم كتلة الخطاف, المصنعة, وتجميعها بشكل صحيح وفقا لمعايير السلامة. يوفر معلومات واضحة عن الأبعاد, مواد, والتجمع, المساعدة في منع الفشل والحوادث.

س 3: كم مرة يجب فحص كتلة خطاف الرافعة?

A3: التفتيش المنتظم أمر بالغ الأهمية. يجب إجراء الفحوصات البصرية قبل كل استخدام, وفحص شامل - التحقق من التآكل, تشققات, أو التشوه - يجب أن يتم ذلك بشكل دوري وفقًا لإرشادات الشركة المصنعة ولوائح السلامة المحلية.

س 4: هل يمكنني تخصيص تصميم كتلة خطاف الرافعة?

A4: نعم. تقدم العديد من الشركات المصنعة خطاف رافعة مخصصًا مصممًا لظروف رفع محددة, قدرات التحميل, والبيئات التشغيلية. تضمن الرسومات المخصصة أن الكتلة تلبي متطلبات المشروع الفريدة.

س 5: أين يمكنني الحصول على رسم كتلة خطاف الرافعة?

A5: يمكنك طلب رسم من الشركة المصنعة للرافعة أو كتلة الخطاف. لأغراض الاستبدال أو الصيانة, ارجع دائمًا إلى رسم المعدات الأصلية أو استشر مهندسًا معتمدًا لضمان التوافق والسلامة.

يعد خطاف الرافعة جزءًا صغيرًا ولكنه قوي من أي نظام رافعة. وجود مفصلة بشكل جيد رسم كتلة هوك الرافعة لا تقدر بثمن للتصميم الآمن, تصنيع, تثبيت, والصيانة. سواء كنت مهندسًا يقوم بصياغة معدات جديدة أو عاملًا يقوم بفحص معداتك, قم دائمًا بالرجوع إلى الرسومات الدقيقة لضمان عمليات الرفع الموثوقة.

تحتاج إلى كتل ربط رافعة مخصصة أو رسومات احترافية? اتصل بنا اليوم للحصول على دعم الخبراء لمشاريع الرفع الخاصة بك!

نحن نقدر ملاحظاتك! يرجى إكمال النموذج أدناه حتى نتمكن من تخصيص خدماتنا حسب احتياجاتك المحددة.

أحدث التعليقات