Die Crane Wire Rope Drum is 'n missie-kritiese komponent wat ontwerp is vir die veilige en doeltreffende spoel van draad tou op verskeie tipes hyskrane.

Kraan draadtou drom dien as die kern van die hys en, in sommige gevalle, die deurkruismeganisme, wat die hyskraan se hysvermoë direk beïnvloed, operasionele gladheid, en algehele veiligheid. Vervaardig van hoë-sterkte staal en ontwerp volgens presiese spesifikasies, ons draaddromme is gebou om uiterste vragte te weerstaan, slytasie weerstaan, en lewer betroubare diens oor 'n lang operasionele leeftyd in veeleisende industriële omgewings.

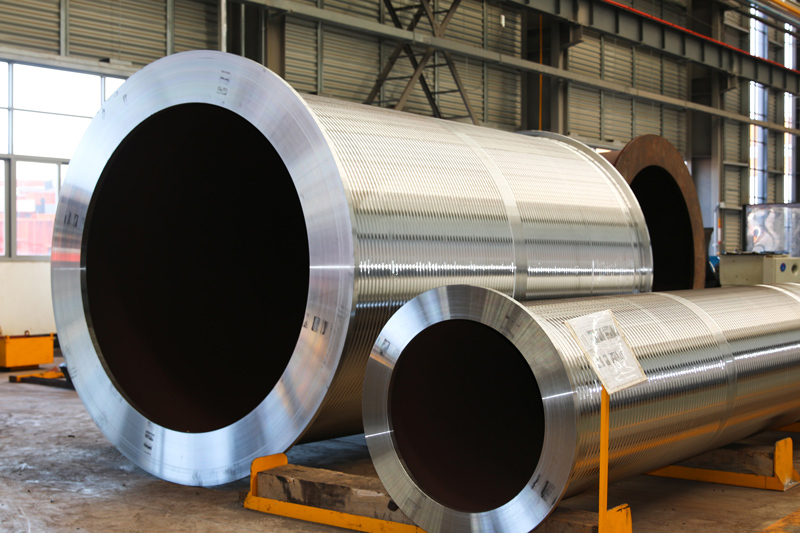

1. Robuuste konstruksie & Premium materiaal

Vervaardig van hoë-opbrengsterkte koolstofstaal of legeringstaal smeewerk.

Ontwerp met optimale wanddikte en strukturele integriteit om maksimum gegradeerde vragte te hanteer en vervorming te voorkom.

2. Presisie-bewerkte groewe

Die tougroewe is noukeurig gemasjineer om by die spesifieke deursnee van die draadtou te pas.

Verseker behoorlike spoel, minimaliseer tou slytasie en verplettering, en verleng die dienslewe van beide die drom en die tou.

3. Gevorderde flensontwerp

Flense is ontwerp met voldoende hoogte om veelvuldige lae tou veilig te bevat, die voorkoming van tou-oorslaan en moontlike ongelukke.

Geronde en gladde flensrande beskerm die draadtou teen skade tydens werking.

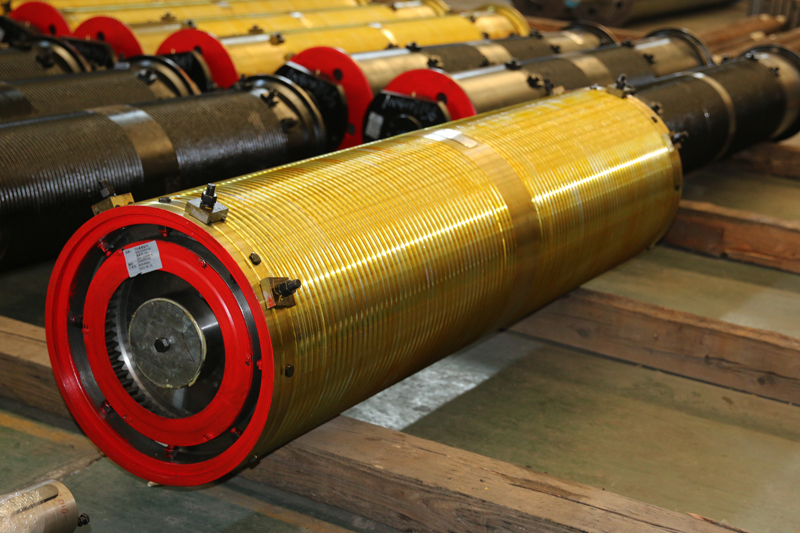

4. Duursame lewensduur & Oppervlakbehandeling

Dromme ondergaan gespesialiseerde hittebehandelingsprosesse (soos blus en tempering) om oppervlakhardheid en vermoeiingsweerstand te verbeter.

Opsionele beskermende bedekkings soos galvanisering of gespesialiseerde verfstelsels is beskikbaar vir uitstekende korrosiebestandheid in moeilike omgewings (Bv., mariene, chemiese).

5. Geoptimaliseerde verbinding & Montering

Ontwerp vir naatlose integrasie met ratkoppelings, gesplinede skagte, of direkte dryfstelsels.

Presisie-bewerkte monteerpunte verseker perfekte belyning met die ratkas en motor, vermindering van vibrasie en meganiese spanning.

6. Multi-laag spoel vermoë

Ontwerp vir gladde en beheerde multi-laag spoel, wat noodsaaklik is vir hyskrane wat hoë hefhoogtes benodig sonder 'n buitensporige groot dromdeursnee.

Let wel: Die volgende tabel verskaf 'n algemene spesifikasiereeks. Gepasmaakte tromme is ons spesialiteit.

| Parameter | Spesifikasie | Note |

|---|---|---|

| Drom kern deursnee | 200 mm - 2,000 mm | Pasgemaakte diameters beskikbaar gebaseer op tougrootte en toepassing. |

| Drom lengte | 500 mm - 6,000 mm | Bepaal deur tou lengte, aantal valle, en lae. |

| Tou deursnee reeks | 8 mm - 60 mm | Groewe word gemasjineer om by die gespesifiseerde tou-deursnee te pas. |

| Flenshoogte | Standaard: 1.5 x Tou deursnee Multi-laag: Soos per ontwerp |

Verseker veilige insluiting van die tou. |

| Max tou kapasiteit | Op na 1,000+ meter | Wissel met dromafmetings en spoellae. |

| Werkslading Limiet (Wll) | 1 Ton – 500+ Ton | Ontwerp met 'n veiligheidsfaktor wat industriestandaarde oorskry (Bv., Vrou, Van). |

| Montage tipe | Enkel- of dubbelflens | Ratkoppeling, Splined skag, of Direct Drive. |

| Materiële graad | Q235B, Q345B, Aisi 4140, of ekwivalente hoë-trekstaal. | |

| Oppervlakbehandeling | Skoot geblaas, Geverf (Standaard), Gegalvaniseer (Opsioneel) |

Ons draaddromme is veelsydig en kan aangepas word vir 'n wye verskeidenheid van hyskraantoepassings, insluitend maar nie beperk nie tot:

V1: Hoe kies ek die regte draaddrom vir my hyskraan?

N: Seleksie hang af van verskeie faktore: die hyskraan se maksimum hysvermoë, die draadtou deursnee, die vereiste toulengte (drom kapasiteit), die aantal spoellae, en die bedryfsdienssiklus. Dit word sterk aanbeveel om ons ingenieurspan te raadpleeg met jou hyskraan se spesifikasies.

V2: Kan jy 'n vervangingsdrom vir my ou of verouderde hyskraanmodel vervaardig?

N: Absoluut. Ons spesialiseer in omgekeerde ingenieurswese en vervaardiging van pasgemaakte vervangingsonderdele. Gee ons die oorspronklike tekeninge, of ons kan presiese mates van jou bestaande drom neem om 'n perfekte te skep, hoë-prestasie vervanging.

V3: Hoe gereeld moet die draaddrom geïnspekteer word?

N: Visuele inspeksies moet voor elke skof uitgevoer word. 'n Formele, gedetailleerde inspeksie moet maandeliks uitgevoer word of volgens u hyskraan se onderhoudskedule en in ooreenstemming met plaaslike veiligheidsregulasies (Bv., Osha, LOLER). Sleutel dinge om na te gaan is groefslytasie, krake, en flensintegriteit.

V4: Wat is die tekens dat 'n draaddrom vervang moet word?

N: Algemene tekens sluit in:

Oormatige slytasie in die tougroewe, skep 'n skerp rand wat die tou beskadig.

Sigbare krake of vervorming op die dromvat of flense.

Die drom is uit-rond of is aan 'n oorlading onderwerp.

V5: Bied jy oppervlak verharding vir die tou groewe?

N: Ja, ons bied induksieverharding of hardverchroomde plating vir die tougroewe as 'n opsionele kenmerk. Dit verhoog slytasieweerstand aansienlik en is ideaal vir hoëdienssiklustoepassings.

Vir verdere tegniese spesifikasies, pasgemaakte kwotasies, of ingenieursondersteuning, kontak asseblief ons verkoopspan.

Ons waardeer u terugvoer! Vul die onderstaande vorm in sodat ons ons dienste by u spesifieke behoeftes kan aanpas.

As a professional heavy-duty lifting equipment, the double trolley overhead crane (also……

Meer ontdek →

What is an Electric Single Girder Crane? electric single girder crane with electric ho……

Meer ontdek →

Product Overview The 15 Ton Overhead Crane is a robust and high-performance material h……

Meer ontdek →

Nuutste kommentaar