Overhead cranes are workhorses in industrial settings, lifting and moving heavy loads with precision. Nietemin, like any heavy machinery, they require regular inspection to ensure safety, prevent breakdowns, and extend their service life. A single oversight during inspection could lead to catastrophic accidents, duur stilstand, or damage to valuable equipment. In hierdie blog, we’ll walk you through a step-by-step guide on how to inspect an oorhoofse hyskraan effectively.

Pre-Inspection Preparation

Before starting the inspection, it’s crucial to prepare adequately to ensure the process is safe and thorough.

- 1. Eerste veiligheid: Secure the area around the crane with warning signs and barriers to prevent unauthorized access. Dra toepaslike persoonlike beskermende toerusting (PPE), including a hard hat, veiligheidsbril, steel-toed boots, and high-visibility clothing. Ensure the crane is powered off and locked out/tagged out (Hart) to avoid accidental activation during inspection.

- 2. Gather Tools and Documents: Collect necessary tools such as a flashlight, measuring tape, wringkrag sleutel, inspection checklist, and the crane’s operation and maintenance manual. Review the crane’s maintenance history and previous inspection reports to identify any recurring issues.

Daily Inspection Checklist

Daily inspections are quick checks performed before the crane is put into operation each day. They focus on visible components and basic functionality.

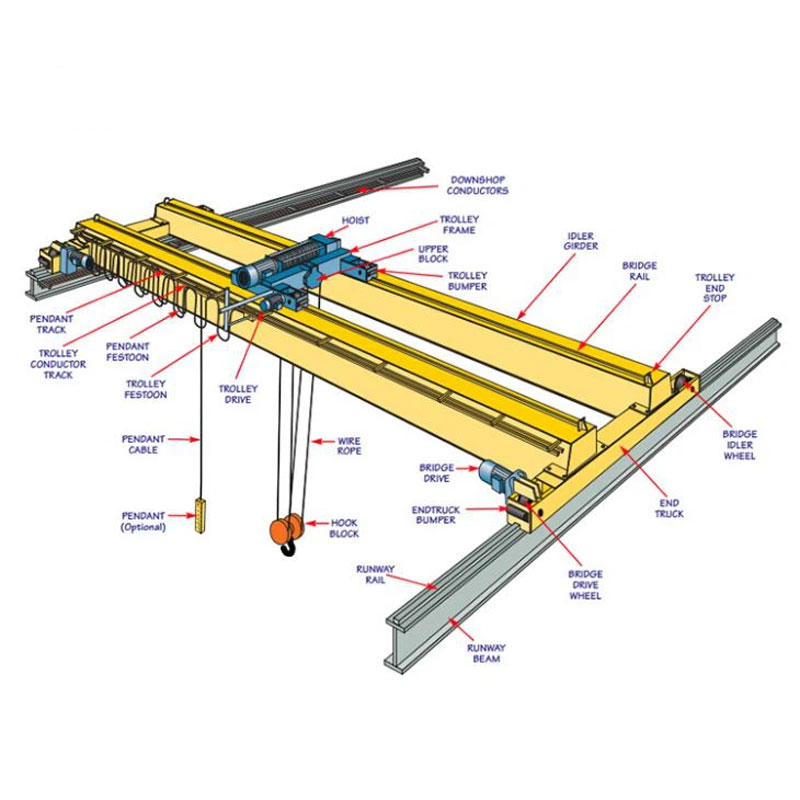

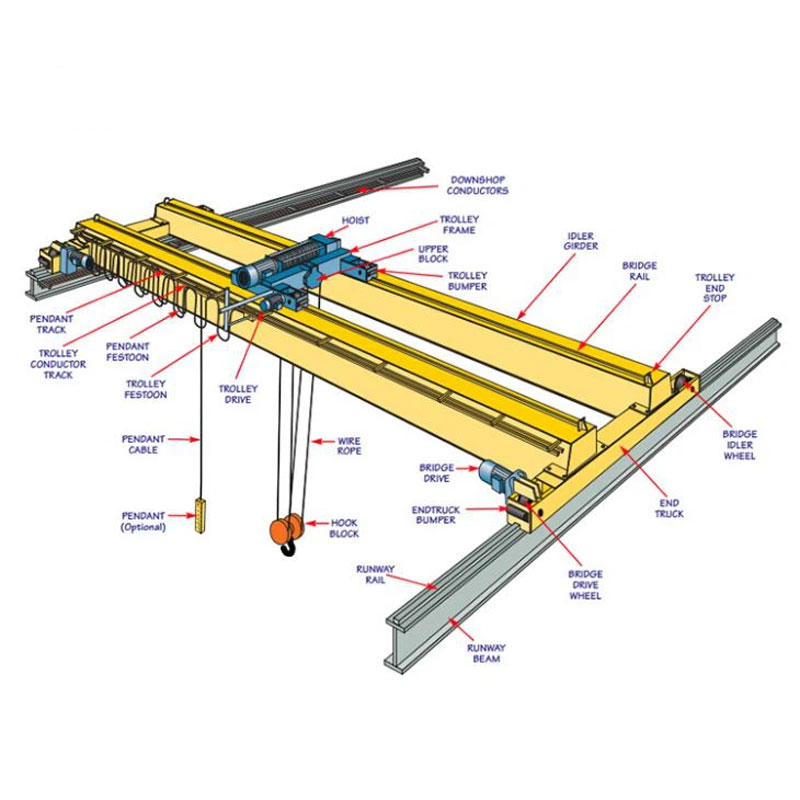

- 1. Hook and Lifting Accessories: Inspect the hook for cracks, dra, of vervorming. Check the crane hook latch to ensure it closes properly and securely. Examine slings, kettings, or cables for fraying, kinks, korrosie, or excessive wear. Verify that all lifting accessories are rated for the intended load.

- 2. Kontroles: Test all pendant or cab controls, including hoist up/down, trolley left/right, and bridge forward/backward. Ensure controls are responsive, and there are no unusual noises or delays in operation. Check that emergency stop buttons function correctly.

- 3. Visual Checks: Look for any loose bolts, neute, or fasteners on the crane structure, trollie, or hoist. Inspect the runway rails for debris, skade, of wanbelyning. Check for oil leaks from the hoist or trolley motors.

Periodieke inspeksie (Monthly/Quarterly/Annual)

Periodic inspections are more detailed and conducted at longer intervals (maandeliks, kwartaalliks, or annually, depending on usage and regulations). They require a closer look at critical components and may involve testing and measurements.

Monthly/Quarterly Inspections

- 1. Hoist System: Inspect the hoist motor for overheating, unusual noises, or vibration. Check the brake system to ensure it holds the load securely when stopped. Examine the gearbox for oil level and quality. Inspect the drum for cracks, dra, or damage to the cable grooves.

- 2. Trolley and Bridge: Check the trolley wheels for wear, krake, of wanbelyning. Inspect the trolley and bridge drive mechanisms, including gears, laers, and couplings, for proper lubrication and functionality. Verify that the bridge end stops are in good condition and function as intended.

Annual Inspections

- 1. Structural Components: Thoroughly inspect the crane bridge, balk, and end trucks for cracks, korrosie, of vervorming. Check welds for signs of fatigue or failure. Measure the deflection of the bridge under a test load to ensure it meets design specifications.

- 2. Electrical System: Inspect all electrical connections, drade, and cables for fraying, korrosie, or loose connections. Test the limit switches (hoist upper/lower limit, trolley and bridge travel limits) to ensure they stop the crane when activated. Check the power supply and voltage to ensure it’s within the recommended range.

- 3. Laai toetsing: Perform a load test with a rated load and an overload (if allowed by regulations) to verify the crane’s lifting capacity and stability. Monitor the crane’s performance during the test for any unusual behavior.

Inspection Frequency Guidelines

The frequency of inspections depends on several factors, including the crane’s usage (number of hours operated per day), the environment (harsh, korrosief, or dusty), and local safety regulations (such as OSHA in the United States or LOLER in the United Kingdom). Here are general guidelines:

- 1. Daily: Before each shift (quick visual and functional checks).

- 2. Maandeliks/Kwartaalliks: For cranes used regularly (detailed checks of critical components).

- 3. Jaarliks: Comprehensive inspection, including load testing (required by most regulations).

- 4. After Major Repairs or Accidents: Inspect the crane thoroughly before putting it back into service.

Post-Inspection Actions

After completing the inspection, take the following actions to ensure the crane is safe to operate:

- 1. Document Findings: Record all inspection results, including any defects or issues found, in a detailed inspection report. Note the date, inspector’s name, and any corrective actions taken.

- 2. Address Defects Promptly: If any serious defects are found (such as cracks in the hook or structural components), take the crane out of service immediately. Schedule repairs with qualified technicians and re-inspect the crane after repairs are completed.

- 3. Maintain Records: Keep all inspection reports and maintenance records on file for future reference and to comply with regulatory requirements.

Onthou, regular inspection is not just a regulatory requirement—it’s a critical step in ensuring the safety of your workforce and the efficiency of your operations. By following this guide, you can keep your overhead crane in top condition and minimize the risk of accidents.

Deel met PDF: Laai af

Nuutste kommentaar